Rotary Dryer Saves Energy, Reduces Cost

October 18, 2012

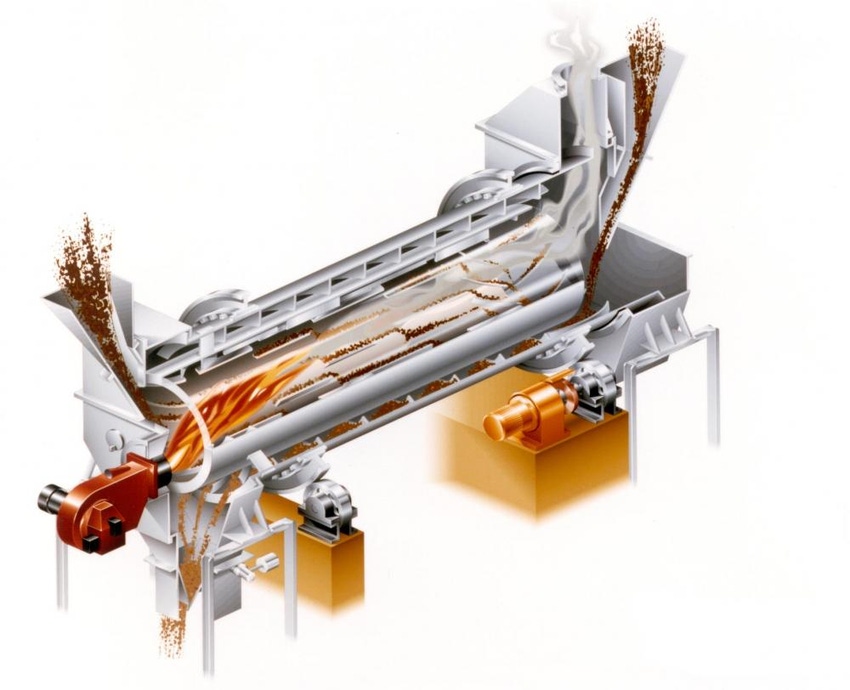

The Allgaier-Mozer TK+ rotary dryer saves energy, reduces cost, and preserves the environment. The efficiency is achieved through a patented double-shell design. Material is dried in the inner dryer shell. A percentage of wet material is then mixed with the already dry material in the outer shell. Residual heat from the dried material evaporates the moisture of the wet material. The additional moisture of the wet material cools the previously dry material through evaporation. More material is dried by heat reuse. In the process, the material is cooled. Depending on initial moisture content of the material, fuel consumption has been shown to be reduced 9-20%. In addition, ambient air is not required for cooling, ambient air is not exposed to the process, energy is saved, costs are reduced, and environmental exposure is limited.

ALMO Process Technology, Cincinnati, OH 513-402-2566 www.almoprocess.com

You May Also Like