April 15, 2014

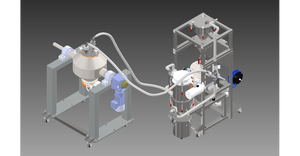

Solids handling specialist, Ajax Equipment, has supplied leading Swedish plastics company Polykemi AB with a stainless steel, twin-screw continuous mixer that mixes plastic granulates with additives and pigments for a range of extrusion machines.

The Ajax continuous mixer replaces a batch mixer that was inflexible in the quantities processed and time consuming to clean. The new mixer has significantly reduced the downtime needed for cleaning equipment between production runs.

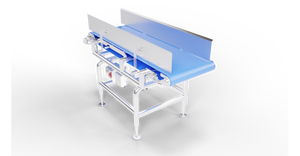

The twin ‘U’ profile mixer features two screw augers with LynFlow paddle blades for effective mixing and handling of the granulates. Continuous mixing offers many advantages over traditional batch mixing, including: greater control over the homogeneity and quality of the mixed granulate compound and the ability to process varying overall quantities and rates.

“We were looking for ways to shorten our production downtime such as cleaning the equipment, especially with an increasing range of mix requirements,” said Roland Persson, operations and maintenance manager at Polykemi AB. “A period of running trials and testing determined that an Ajax continuous mixer could provide the solution. The twin mixer features an almost food-quality high standard of finish and quick release couplings ensuring easy cleaning of the machine. The mixer also has Makrolon window-style covers, allowing the mixing process to be monitored.

For related equipment reviews, articles, and news, visit our Mixers & Blenders Equipment Zone

Click here for information about the International Powder & Bulk Solids Conference & Exhibition

You May Also Like