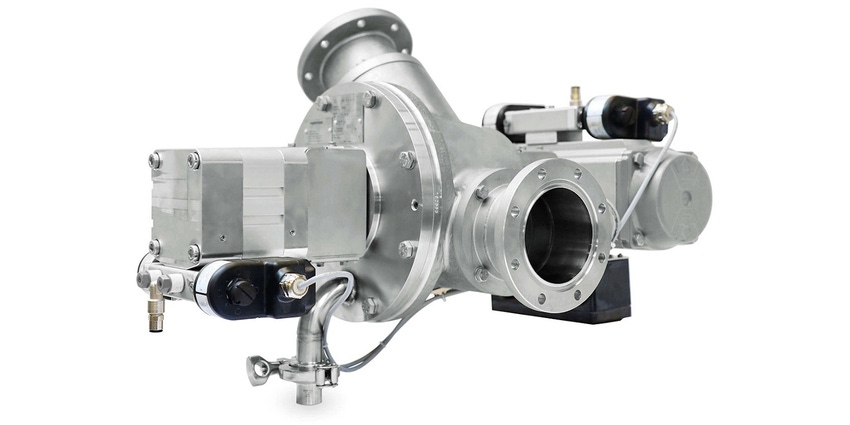

The new single-channel conical design of the WYK-CIP diverter valve is ideal for residue-free cleaning.

September 30, 2020

The new single-channel conical design of the WYK-CIP diverter valve is ideal for residue-free cleaning in manufacturing processes with frequent product changes, where highest requirements in hygiene and purity apply.

The WYK-CIP is suited for inline material handling of hygienic and difficult to handle powders, such as whey powder, lactose, dried milk powders, and infant formula. This valve can be used in pneumatic conveying systems, in order to divert transfer of the powder to different locations, and it is often used in return lines in spray drying applications.

The fully automatic CIP (clean-in-place) design permits complete purging of all product residues after the automatic cleaning process without dismantling and without manual cleaning. Due to a retractable rotor assembly, the rotor can be pulled slightly out of the housing, thus allowing the cleaning solution to rinse all product contact surfaces within the valve. In addition, specialty purge openings in the actuator plate enable an intense rinsing flow and complete discharge of the rinsing effluent.

This CIP design is particularly advantageous for locations that are typically difficult to access. By reducing the downtime for cleaning, the CIP concept saves both time and money.

Coperion K-Tron Salina Inc., Salina, KS 785-825-3830 www.coperion.com

About the Author(s)

You May Also Like