A rotary airlock valve is a vital component on a conveying or handling line

April 14, 2022

Brittany Dollimore, sales manager, ACS Valves

When it comes to manufacturing and processing bulk solids, powders, and granulates in the food processing, pet food processing, pharmaceutical processing, or grain handling industries, nothing beats efficiency.

On a conveying or handling line, one of the most vital components is the rotary airlock valve. When it comes to maximizing efficiency for split feeds or conveying lines that handle multiple ingredients, it is worth taking a moment to consider the many rotary valve options available.

Valves designed for split feeds allow processors to change ingredients on the fly, giving them the opportunity to change, which products they want to prioritize at any given time. These valves also help processing lines remain contamination-free, keeping gluten, nuts, and other allergens separate, ensuring the health and safety of the end user.

To help processers make the right decision when it comes to purchasing rotary valves for bulk ingredients, this article will offer a brief overview of the best configuration options available to keep rotary valves working at peak capacity and NFPA compliance, maximizing efficiency on any conveying line.

Multi-Port Rotary Valves Provide Maximum Adaptability

On any processing line, the humble rotary valve is working overtime to keep everything moving. On a line where solids need to be split, additional ports can be the difference between success and failure, making a multi-port option the first and most important consideration for anyone in the market for high-efficiency rotary valves.

In nearly all applications, more ports mean fewer problems. Investing in a multi-port rotary valve system will keep lines running smoothly, maximizing production and minimizing downtime due to maintenance or repair issues.

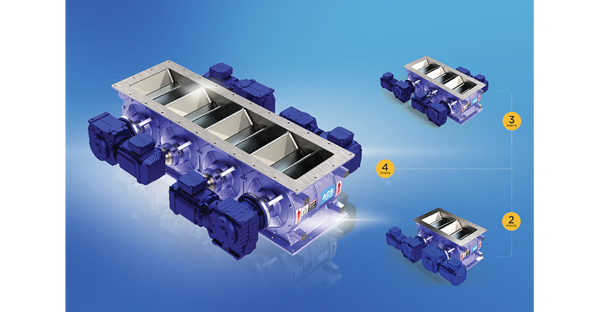

Multi-port valves break up very large pneumatic systems into smaller, more manageable systems, splitting one large capacity valve into independent feeds. Each compartment has its own rotor and direct-drive motor, so they can run independently or simultaneously as necessary.

A multi-port valve works well in almost any high-volume powder or bulk application, but it’s especially recommended for any line conveying free-flowing bulk material stored in large silos, such as grains or food additives.

Generous Flowthrough Capacities and Downtime Reduction

A valve with multiple compartments allows for one elongated discharge to feed a single system, or for one line to feed up to four different conveying systems for intermittent feeds, depending on need. Because there is always at least one compartment that keeps running even if there are problems in another section, a multi-port system virtually eliminates downtime.

Thanks to independent drives and separated airlock compartments, a potential breakdown in one airlock doesn’t stop the others from continuing to feed, meaning issues can be addressed on the line without interrupting productivity. Because the valve uses common parts, it’s also faster to order replacements, meaning less downtime for repairs and maintenance.

Maintaining NFPA Compliance

The sheer size of industrial valves can sometimes make it challenging to adhere to precise clearances required for NFPA compliances, but multiple ports make all the difference.

This is because individual compartments have a more compact design compared to larger-footprint options. NFPA clearances can be challenging to meet in larger airlocks, but multiple ports actually make it easier to maintain the correct rotor tolerances essential for NFPA safety and compliance.

In addition, direct drives in each compartment allow for independent operation, where separate material flow can be controlled.

Finally, sheer adaptability makes for better efficiency overall, thanks to the option for one elongated blow-through adapter to feed one system compared to multiple blow-through adapters connecting to different line feeds.

The beauty of the multi-port valve lies in its versatility, and a rotary valve expert can help determine the best configuration for any conveying system.

Say Goodbye to Build-up with Quick-Cleaning Features

Another important consideration when it comes to maximizing valve efficiency is convenience of cleaning.

On a processing line, there is almost always an inevitable build-up of residue on valve parts. Valves with quick-cleaning features will naturally boost productivity, safety, compliance, and material flow by virtue of making it easier to clean.

When processing bulk pellets, granulates, or powders, especially in a sanitary application like food, pet food, or pharmaceuticals, it’s important not only to limit build-up but also to ensure that nothing hinders the cleaning process.

Valve cleaning typically requires access the valve’s internals by disassembling the endplate. Depending on the size of the equipment, the disassembly and re-assembly process can take up precious hours of downtime, especially with larger and heavier valves.

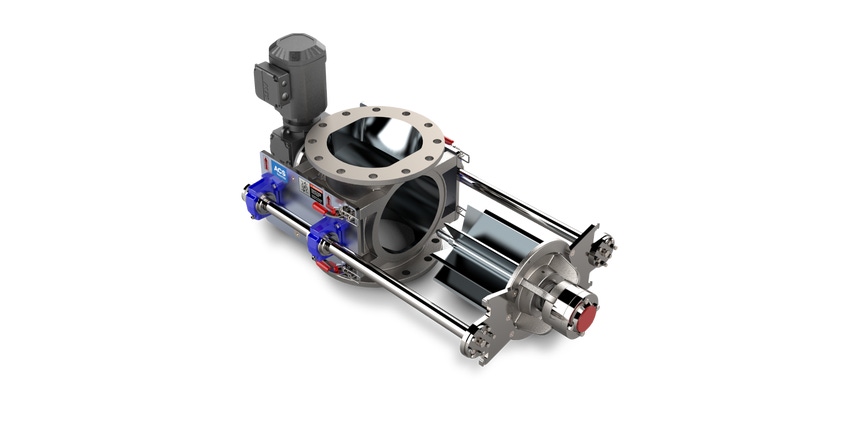

Advanced quick-clean or easy-clean rotary valves built on a rail system maintain rotor and endplate alignment during disassembly and endplate re-alignment during re-assembly. Thanks to quick-release handles that slide out easily, the rotor assembly makes cleaning possible without tools or heavy lifting. This allows single-step access to rotor and internal surfaces, making for more efficient and thorough cleaning, validation, and inspection — which is especially important in sanitary or food-grade applications.

Rotor Types for All Situations

Whatever the specific processing need, there is a rotor type for every line and every job.

Closed-end rotors are used with extremely abrasive material to protect the outboard bearings and endplates, while flex tip style rotors are the preferred choice for fibrous materials like flakes or chips.

For materials that are sticky or tend to pack, a radius pocket rotor is a reliable workhorse. Unlike the standard V-shaped rotor pocket, this rotor's pockets are U-shaped, which minimize material packing in the crease of the rotor vane, making it optimal for sanitary or food-grade valves.

Whenever granulated sticky materials are conveyed, the valve interior can become coated, clogging up the insides of the valve. Bolt-on serrated tip rotors clean as they work, scraping away granulated or sticky materials that coat the interior, and the two bolt-on serrated tips are counter aligned for full scraping coverage.

Where moderately abrasive material is conveyed, tips will wear prematurely. Adjustable tip rotors allow for easy replacements. While they aren’t recommended for food or sanitary applications, adjustable tips can be used in both open and closed end rotors, making them extremely versatile.

Coatings and Construction Material

The last consideration when choosing the right rotary valve — but certainly not the least important — is the construction material and coating.

Simply put, the more time spent choosing the right materials, the less time will need to be spent doing maintenance on the processing floor. The right materials and coatings will support easier cleaning and better longevity in the long run, so neglecting this consideration is not recommended.

While certain chemicals can cause corrosion for valves that aren’t properly treated, food applications present an altogether different challenge. Fine, sticky materials such as sugar, flour, and some pet food ingredients are classic cases for build-up. As material accumulates inside the valve, it can cause major havoc with the flow rate, pocket fill, and might possibly cause contamination.

But challenges don’t stop there. Salt is a classic example of a material that needs help on both fronts: it’s corrosive and prone to sticking. In each case, material wears down the valve’s rotor and internals, making it necessary to replace parts more often and reducing the valve’s overall lifespan — unless the proper materials and coating are chosen from day one.

The proper non-stick coating helps materials slide off the valve and makes the cleaning process easy, maximizing safety and efficiency side-by-side.

When choosing the right rotary valve, there are four key considerations to keep top of mind.

1. Strong Construction

High-quality metallurgy with strong composition and solidification prevents the formation of stress cracks where contaminants can build up. For example, stainless steel housings are best-in-house options for industries with sanitary concerns — essentially anywhere food and pharma products are processed.

2. Internal Coatings

Valves should come with their own factory-applied coatings. Top-tier choices such as tungsten coatings prevent surface cavities and other imperfections from forming inside the valve. Coatings help reduce contaminant build-up, reduce wear on the valve, and improve the flow of hard-to-convey materials.

3. Glandless Sleeve-Style Shaft Seals

Bearing seal leaks pose a double pronged challenge in the form of both a cleanup and contamination risk. Luckily, a Teflon “sleeve-style” shaft seal with a triple barrier design for extra security can help mitigate both risks. With this improved shaft seal design, time-consuming pusher plate adjustments are also bypassed.

4. Sloped Planes and Rounded Edges

Finally, with rotors with U-shaped pockets, you can effectively promote material flow and prevent dead zones all at once.

Ensuring safety, efficiency, and compliance doesn’t simply come down to the valve types installed on a processing line; the materials and even the coating contribute to valve performance as well.

Final Thoughts

A technical rotary valve expert can tell you more about choosing the right valve, configuring it with the right rotors, coatings, and accessories, and boosting efficiency in your conveying system. Look for products sold through a global network of sales representatives and supported by a corporate staff of applications engineers and customer services technicians.

If you have concerns about regulatory compliance — whether it’s FDA, USDA, or NFPA — a technical expert can help.

Brittany Dollimore is sales manager at ACS Valves, Caledonia, ON, Canada. For more information, call 800-655-3447 or visit www.acsvalves.com.

You May Also Like