May 14, 2011

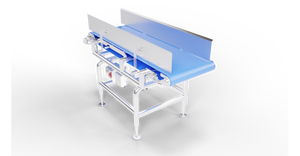

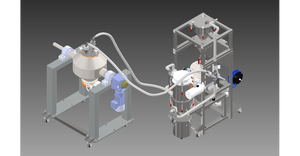

Thermo Fisher Scientific Inc., a world leader in serving science, has announced a collaboration with integrated process technology provider Glatt GmbH to deliver continuous twin-screw granulation and drying solutions for the pharmaceutical industry. Together, the two companies provide a one-stop solution for satisfying customer demands from powder handling to tablet production.

“To improve performance and yield in production processes, pharmaceutical companies are increasingly adopting continuous processing, especially for granulation,” said Markus Schreyer, vice president and general manager of the Thermo Fisher Scientific’s material characterization business. “Our customers have confirmed that twin-screw granulation is the next step in continuous processing because it simplifies scale-up, and we’re able to offer a comprehensive twin-screw granulation portfolio to meet their specific needs, from research and development to production.”

While many pharmaceutical companies still use batch process technologies, interest in continuous processing has increased because companies want to further reduce manufacturing costs and improve performance. “Glatt already serves customers using continuous process technologies in the food, feed, and fine chemical sectors, and the pharmaceutical industry is next for this innovation,” said Thomas Hofmaier, head of Glatt’s pharma process technologies business unit. “Combining Thermo Scientific twin-screw granulation technology with Glatt’s continuous drying technologies, as well as our complementary expertise in system integration and applications, offers a unique and beneficial solution to our customers.”

Thermo Fisher Scientific, one of the pioneers in rheology, successfully supports a wide range of industries with its comprehensive Thermo Scientific material characterization solutions. Material characterization solutions analyze and measure viscosity, elasticity, processability, and temperature-related mechanical changes of plastics, food, cosmetics, pharmaceuticals and coatings, chemical or petrochemical products, plus a wide variety of liquids or solids. For more information, visit www.thermoscientific.com/mc.

You May Also Like