September 14, 2010

Gravity Metal Detector

Gravity Metal Detector

The Phantom gravity metal detector is ideal for inline inspection of dry, powder, or granular products that can be gravity fed through a pipe from a processing machine. The detector is built with anti-static UHMW pipes, air control, and a ceiling support frame. A selection of several aperture sizes is available and an optional automatic reject valve can remove contaminated product from the flow. Fortress Technology Inc., Toronto, ON, Canada 888-220-8737 www.fortresstechnology.com

Click to enlarge

Precision Lump BreakerWith a combination of engineering excellence and precision construction, the Delumper DC2085L crusher breaks up lumps, crushes minerals, improves product consistency, facilitates mixing, drying, and conveying, and keeps process lines running smoothly. This powerful lump breaker reduces a wide range of materials including chemicals, sugar, food, mineral, salts, plastics, and pharmaceuticals to desired output. It utilizes individually replaceable teeth mounted on a smooth rotating drum for a non-churning, positive once-through chopping action. Its design reduces solids to basic grain size without overgrind, heat rise, or fines. This precision unit runs with minimal vibration or noise. It features a seamless, one-piece stainless steel body and wide mounting flanges for easy connection to systems or hoppers. Additional features include shaft seals with purge capability, a choice of direct or belt drives. Franklin Miller Inc., Livingston, NJ 973-535-9200 www.franklinmiller.com

Triple Shaft Mixer

Triple Shaft Mixer

Designed for multiple mixing requirements such as high-speed dispersion, emulsification, and particle size reduction, the VersaMix triple shaft mixer is now available with a solid/liquid injection manifold (SLIM) system. The incorporation of this high-speed powder induction technology adds to the VersaMix’s flexibility and broadens its applicability while manufacturing viscous materials. When introducing low-density solids, agglomerates can form when using top-entry slow speed mixers. In some cases, this lumping is irreversible – subsequent shearing will not eliminate the ‘fish eyes’ that have formed, restricting plant operators to very slow addition of powders which hurts production throughput. The SLIM system injects materials directly into the rotor/stator agitator of the VersaMix. Charles Ross and Son Co., Hauppauge, NY 800-243-7677 www.mixers.com

Click to enlarge

Metal DetectorThe Insight PH is offered with advanced plug-and-play architecture featuring an array of new communications options – USB, SCADA, wireless and standard ethernet - designed to meet the requirements of both systems integrator and manufacturer to equal degree. In conformance with GMP, the unit is designed and constructed in compliance with 21 CFR Parts 210 and 211 and is now sealed to IP66/NEMA 4X. It is compatible with all leading tablet presses and dedusters, while detecting metal at throughputs up to 30,000 units per minute and rejecting contaminated material using a variety of reject options including wash-in-place and dust-tight. Lock Inspection Systems Inc., Fitchburg, MA 978-343-3716 www.lockinspection.com

Shut-off Valve

Shut-off Valve

Mucon Disc Valve is the reliable, durable, low-maintenance shut-off valve for the powder processing industry. Often used in toxic or hazardous environments, the Mucon Disc Valve, when used in pairs and fitted with a safety vented spool, form an airlock for the safe loading of components into dangerous processes. Not only do they constantly control the flow of product, they insure it stays within the system and does not leak into the atmosphere. They also perform well under pressure and at elevated temperatures. The Mucon Disc Valve is the non-jamming, tough valve for the powder processing industry. Kemutec Powder Technologies, Bristol, PA 215-788-8013 www.KemutecUSA.com

Click to enlarge

Bulk Bag Discharger with Integrated Dust Collection SystemThe patented Material Master bulk bag discharging system offers features that maximize production efficiency. An integrated pulse-jet dust collection system returns collected dust to the product stream and features stainless steel product contact surfaces. Automatically sequenced Flow-Master bag massagers and Power-Flo bag impactors promote material flow, while a powerful Flo-Lock discharge spout closure system halts material flow for partial bag discharging. A Sure-Seal actuated spout clamping system seals the bag discharge spout during the discharge cycle. Units are custom designed to application requirements. Material Transfer & Storage Inc., Allegan, MI 800-836-7068 www.materialtransfer.com

Desiccant Dehumidification Systems

Desiccant Dehumidification Systems

These liquid and dry desiccant dehumidification systems deliver precise, reliable energy-efficient temperature and humidity control for conveying and storing dry bulk products. Common applications include silos as well as unloading and conveying systems. In addition to providing consistent temperature and humidity control, the systems: eliminate mold growth; neutralize airborne microorganisms for bacteria-free air; improve product quality and extend shelf life; lower production costs for heat sensitive drying; maximize production rates for eliminating downtime; prevent product sticking and lumping; help avoid blockages in conveying lines; stop product from sticking to silo walls. All equipment is made of Fiber Reinforced Plastic (FRP) with industrial-grade construction to provide less maintenance and long equipment life. Kathabar Dehumidification Systems Inc., Buffalo, NY 732-356-6000 www.kathabar.com

Click to enlarge

Rotary Continuous MixerThis sanitary rotary continuous mixer blends bulk ingredients in ratios as extreme as one part per million with 100% uniformity regardless of disparities in the bulk densities, particle sizes, or flow characteristics of ingredients. Capacity ranges from 85 cu ft/hr at 1-minute residence time to 42 cu ft/hr at 2-minute residence time. Mixing flights in slowly rotating cylinder distribute ingredients thoroughly and gently while eliminating internal restrictions where material could plug or accumulate. Optional internal spray line allows uniform introduction of a liquid additive for spray coating, de-dusting, perfuming, agglomerating, and conditioning of materials. Munson Machinery Company, Inc., Utica, NY 800-944-6644 www.munsonmachinery.com

Combination Bulk Bag Unloader

Combination Bulk Bag Unloader

This bulk bag unloader is specifically designed to ensure plant and worker safety when processing hazardous powders or bulk solids. The stainless steel frame of the unloader serves as the basis for a number of options engineered for maximum dust containment. Operators can easily untie bulk bags or work with smaller bags within a sealed dump box station equipped with viewing ports and heavy-duty gloves that protect against contact with the material. Filtration options up to 1 micron of efficiency are available to capture and confine material within the unit. To further ensure material stays within the process, an integrated bag compactor allows the operator to dispose of minor ingredient bags safely through a pass-through port from the glove box dump station.Pneumatic agitators assure material flow from the bulk bag unloader while air pads in the hopper assist with product discharge. The unloader is available as hoist and trolley or forklift style. Hapman, Kalamazoo, MI 269-382-8228 www.hapman.com

Click to enlarge

Nano Dust Collector FilterThis new HemiPleat Nano dust collector filter offers higher filtration efficiencies, longer service life, and lower pressure drop than competitive nano fiber filters, for energy savings and enhanced performance. The manufacturer uses a new technology to apply a thick layer of highly durable nano fibers to the surface of the patented HemiPleat filter, yielding a MERV 14 efficiency rating - higher than that of most competitive filters. The media is strong enough to handle difficult dust challenges and it will withstand rigorous pulse-cleaning for all types of dry dust applications, bringing longer service life and lower operational costs. The product line includes MERV 14 and MERV 16 efficiency options, with a choice of high performance standard or fire retardant cellulose-blend base media. Camfil Farr APC, Jonesboro, AR 800-479-6801 www.farrapc.com

Food and Dairy Feeder

Food and Dairy Feeder

The Mechatron 3-A feeder is designed specifically for use in the food and dairy industries where equipment and processes must meet 3-A sanitary levels or equivalent. All welds, radii, seals, surface finishes, gaskets, and contact and non-contact materials meet 3-A standards. Available product features include AC and DC drive packages, an FDA/USDA-accepted Coni-Flex flexible conical feed-hopper, helix configurations for feed rates from 0.30 to 330 cu ft/hr and an ability to disassemble, clean, reconfigure, and service from the non-process side of the feeder. A domed hopper cover and open bottom frame speeds and optimizes draining during and after wash-down cycles. Smooth, crevice-free product contact surfaces at 32 micro in. or better help prevent the formation of bacteria. Schenck AccuRate, Whitewater, WI 800-558-0184 www.accuratefeeders.com

Click to enlarge

Vibratory Bin Activating FeederThe Gyro bin activating feeder produces 360° of pure gyratory motion to positively discharge granular materials from bins, storage silos, and hoppers at any desired feed rate. At the heart of the feeder is the drive that produces 360° of radial force, creating a uniform circular motion on all parts of the feeder. It is this annular radial vibratory motion that imparts the ultimate force, assuring a constant and reliable material flow. This also minimizes any material stratification in the storage silo or bin and develops a predictable and positive flow of material upon demand. The feeder can operate either continuously or as a start and stop operation. Dynamic Air Inc., St. Paul, MN 651-484-2900 www.dynamicair.com

Dump Hopper

Dump Hopper

This bag dump hopper is designed to provide a quick, easy, and virtually dust-free way of dumping and filling process systems with material received in paper bags. Ruggedly built for continuous long-lasting operation, the hopper’s design incorporates a baffle and bin vent (to attach to a central dust collector) or optional bin vent filter over the dump area to maintain a dust-free work environment while providing a fast and effective means to discharge your dry solids products. The hopper features a hinged door to keep foreign materials from falling into the process stream when not in use and an expanded metal grid to prevent bag pieces from getting into the process as well. An integral exit cone is easily transitioned to accommodate other upstream or downstream equipment such as a feeder, flexible screw conveyor, rotary valve for pneumatic conveying, and other application specific requirements. Metalfab Inc., Vernon, NJ 800-764-2999 www.metalfabinc.com

Click to enlarge

Rotary Airlock for Abrasive MaterialsThe Type 6 airlock is constructed to withstand the most abrasive of materials. It is built with rugged Ni-Hard steel, a closed-end rotor constructed of carbon steel, and Stellite on wear surfaces. These features combined with its toughness, make this a long-lasting airlock. Smoot, div of Magnum Systems, Kansas City, KS 800-748-7000 www.magnumsystems.com

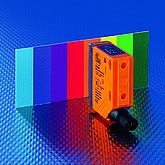

Color Identification Sensor

Color Identification Sensor

The O5C500 color identification sensor can verify, sort, and error-proof the presence of objects by color in fast-moving applications. The sensor uses RGB technology to emit pulses of red, green, and blue light from the its transmitter. The sensor‘s receiver evaluates the pulsed light reflected from the target to determine the best color for identification. The high-resolution color sensor offers five selectable tolerance steps to determine even the slightest differences in color shade. A simple, one-step teach function quickly establishes the parameters of an application. An auto-detect output automatically sets a single switching output to PNP or NPN operation. The sensor is programmable light-on or dark-on. ifm efector inc., Exton, PA 800-441-8246 www.ifm.com

Click to enlarge

Electric Bin VibratorThe Series EBV electric bin vibrator incorporates adjustable force features without creating irritating noise. The low-amperage draw at 115V reduces power consumption and makes the vibrators useable in any area. The EBV eliminates drawbacks associated with non-adjustable constant force unit. The conventional fix force units are sized with narrow operating limits and may not move material out of bins or pack the material in containers if the moisture content changes. With the ability to change the force of the EBV vibrator, you increase your application flexibility, reduce equipment downtime, minimize added operator expense, and improve safety by avoiding situations where the operator must climb up the bin or chute to loosen the material. Dwyer Instruments Inc., Michigan City, IN 800-872-9141 www.dwyer-inst.com

Industrial Vacuum Cleaners

Industrial Vacuum Cleaners

The S2 and S3 industrial vacuum cleaners feature several innovations: The Longopac collection system – an “endless” bag that can be dispensed as needed to your desired length. Once filled, it can be cut, sealed, disposed, and restored for a new use; LED indicators that automatically monitor filter performance and increase productivity; solid and liquid level LED sensors (100 L machines only) that automatically shut-off the machine when maximum capacity is achieved; ergonomic design for ease-of-use; includes an accessory storage tray; multiple configurations, including stainless steel construction, automatic filter cleaning systems, and HEPA filtration; dozens of hose, filters, and accessories to meet any industrial cleaning challenge. Nilfisk CFM, Malvern, PA 800-645-3475 www.NewNilfiskVacuums.com

Click to enlarge

Fluidizer DiskThe Model FD fluidizer disk combines aeration and vibration to solve the most difficult bulk solid flow applications. The special design creates a vibration as the air flows between the pads boot and bin wall. This is an effective flow aid for all types of dry products. Plus the FD does not require a specific air pressure for operation. Your pneumatic system pressure can range from 29 to 87 psi. Dwyer Instruments Inc., Michigan City, IN 800-872-9141 www.dwyer-inst.com

Adjustable-Depth Bearing Temperature Sensors

Adjustable-Depth Bearing Temperature Sensors

These adjustable-depth bearing (ADB) temperature sensors have been designed to allow the depth of the probe to be adjustable depending on your application. The ADB series is available with probe lengths of 2, 4, or 8 in. and screw directly into a bearing housing through the existing 1/8-in. NPT threaded grease zerk. There is no need to remove the sensor for bearing lubrication since each sensor is fitted with its own grease zerk. The ADB series have NTC type thermistors that allow for continuous temperature monitoring and can be connected to a PLC or to a hazard monitoring system, such as 4B’s T500 Hotbus Elite or Watchdog Elite. The ADB Series of bearing temperature sensors are Class II, Div. 1 approved. 4B Components Ltd., East Peoria, IL 309-698-5611 www.go4b.com

Click to enlarge

High-Speed Bag TurnerHeavy-feed bagged products are oriented gently, positively, and almost 30% faster than previously possible by A-B-C’s high-speed pop-up repositioner for the company’s bag palletizers. This device turns bags 90, 180, or 270º, depending on the desired pattern, allowing manufacturers to position the product so that the bottom (butt) of the bag or the printed panel will face out when palletized. The turner is operated by the Intelligent Control system of the palletizer, programmed for each pallet configuration. When bag orientation is required, the bag is conveyed into position above the turner, and the turner moves vertically to lift the bag from below, supporting the entire weight of the bag as it is positioned. This efficient action maintains the bag’s shape for efficient palletizing. If product orientation is not required, the repositioner retracts below the roller conveyor and bags are smoothly transported above the turner for palletizing. A-B-C Packaging Machine Corp., Tarpon Springs, FL 800-237-5975 www.abcpackaging.com

Fabric Duct for Air Dispersion

Fabric Duct for Air Dispersion

ChemSox is the HVAC industry’s first fabric duct air dispersion system for chemically harsh environments in metal plating, paper/pulp, wastewater treatment, chemical processing, plastics manufacturing, petrochemical, battery manufacturing, and other highly corrosive and caustic industries. Its recyclable, inert high-density polyethylene (HDPE) fabric outlasts conventional polyester-based fabric duct and accessories, which are subject to brittleness and cracking in harsh environments. Additionally, ChemSox is up to 50% less expensive than the materials and installation costs of coated metal, aluminum, and stainless steel ductwork, which is typically scheduled for permanent replacement cycles in corrosive spaces. Although it was developed for chemical resistance in environments using substances such as hydrochloric acid, sodium sulfate and isopropanol, it also resists the corrosiveness of many other chemicals as well. DuctSox Corp., DuBuque, IA 866-382-8769 www.ductsox.com

Click to enlarge

Multi-Axis Bucket ConveyorThe multi-axis Elecon bucket conveyor and elevator system moves material in three different directions for optimum flexibility in planning a material handling system within a production facility. The conveyor uses cantilevered buckets that move vertically, horizontally, and can turn any direction up to 90º without having to transfer the load being conveyed. This feature lets users fit the conveyor within their production facility instead of modifying their facility to accommodate the material handling system. The multi-axis capability of the unit is the result of its patented chain design and the cantilevered wedged-shaped buckets that come together and overlap at the load station. Gough Econ, Charlotte, NC 800-264-6844 www.goughecon.com

Dust Collector Pulse Timer

Dust Collector Pulse Timer

The IntelliPULSE pulse-jet timer for baghouses and dust collectors reduces energy costs and offers direct connection to PLCs with user specified field bus communications such as Devicenet, Ethernet, Modbus, and Profibus. The intelligent pulse-cleaning control technology minimizes compressed air use during filter cleaning, reducing energy consumption. No tuning is required. Compressed air energy savings up to 90% over continuous pulse-cleaning methods and up to 40% over pulse on demand methods are reported. Compact DIN rail packaging makes for easy mounting and field service. FilterSense, Beverly, MA 978-927-4304 www.filtersense.com

Click to enlarge

Product Recovery SystemThe Taskmaster TM1600PRS product recovery system (PRS) quickly separates bulk product from packaging providing a solution for recycling, disposal, or reprocessing. The unit can separate dry products from their packaging to reduce waste, cost, and make both the product and packaging available for recycling or reprocessing. It uses a Taskmaster shredder to shred the packaging before sifting both the packaging and contents through a powerful separator, allowing the operator to recover or dispose of the product. The efficiency of this unit will allow for cost savings in both waste and labor and can quickly pay for the equipment cost in savings. The system is provided in carbon steel construction as well as in stainless steel. An automatic wash system can be provided as an option. The shredder is quiet in operation and easy to use and maintain. Franklin Miller Inc., Livingston, NJ 973-535-9200 www.franklinmiller.com

Plastic Shaft Collars

Plastic Shaft Collars

These plastic clamp-type shaft collars are machined from various thermoplastics to match process applications requiring chemical resistance and frequent wash-downs. Collars are offered in one- and two-piece styles and are supplied with stainless steel clamping screws for use in FDA- and USDA-approved processing equipment and conveyors. Machined from Teflon, Delrin, nylon, and other thermoplastics, they let designers specify collars that precisely match other system components. Available in 1- to 4-in. I.D. bore sizes, they are suited for many applications requiring chemical resistance and/or frequent washdowns such as food and pharmaceutical processing. Stainless steel, steel, and anodized aluminum collars are also offered. Stafford Manufacturing Corp., North Reading, MA 800-695-5551 www.staffordmfg.com

You May Also Like