Sign up for the Powder & Bulk Solids Weekly newsletter.

January 6, 2011

6 Min Read

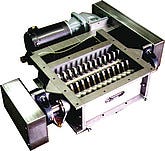

Click to enlarge

High-Capacity CrusherThe Delumper 2020LP is a powerful, high-capacity crusher that easily reduces large volumes of wet, dry, sticky, hard, and soft agglomerates and lumps to a free-flow condition. The unit’s efficient low-friction cutting action is excellent for processing large quantities of chemicals, fats, sludge cake, plastics, waste, and more. This straight-thru unit utilizes specially designed teeth that rotate through a bar cage with a complete self-cleaning action. Solids are reduced to their basic grain size without overgrind, heat rise, or fines. Lumps up to the full inlet opening size can be processed. The unit runs at low speed and creates little vibration or noise. The unit is solidly constructed with a one-piece, seamless body, and has individually replaceable teeth. It is supplied with lip-type shaft seals and heavy tapered roller bearings. Franklin Miller Inc., Livingston, NJ 973-535-9200 www.franklinmiller.com

Click to enlarge

Sanitary Lump Breaker with Side-Removal ScreensThe model RDC1515-SS sanitary lump breaker features side-removal bed screens for rapid, thorough wash down. Materials entering the 15-in. square inlet are reduced in size by dual rotors with three-point, single-piece, stainless steel breaking heads rotating with minimum clearance inside a curved, perforated bed screen. On-size material exits through apertures in twin bed screens ranging from 1/32 to 2 1/2 in. in diameter. The low-profile unit is designed to fit in restricted spaces between bulk storage, processing, and packaging equipment. Whereas conventional units must generally be unbolted from upstream and downstream equipment to access bottom-mounted bed screens, the new unit with side-removal bed screens can remain in place, allowing thorough sanitizing in a fraction of the time. Constructed of stainless steel finished to sanitary standards, the unit is suitable for food, dairy, and pharmaceutical applications, as well as industrial applications where cross-contamination is a concern. Munson Machinery Company, Inc., Utica, NY 800-944-6644 www.munsonmachinery.com

Click to enlarge

Vibratory Grinding MillsThese versatile Vibro-Energy grinding mills are available for fast, low-cost particle size reduction to sub-micron range. The Vibro-Energy grinding action achieves higher output per input horsepower, precise control of size and distribution. Product contamination from media and lining wear is virtually eliminated. Maintenance costs are low because of few moving parts and replaceable linings made of abrasion-resistant metal, ceramic, or elastomers. The mills’ vibratory motion, coupled with the use of cylindrical media, allows a dense packing of the media bed, assuring maximum media surface contact and minimum void area when operated under a low-energy condition. Feed materials as large as 300 microns can be reduced to sub-micron sizes. Sweco, Florence, KY 800-807-9326 www.sweco.com

Click to enlarge

Lab Size Universal MillThe versatile 5H universal mill offers interchangeable grinding media. Designed for laboratory and pilot plant applications, it is ideal for product/process development and is directly scalable to R&D, pilot, and production applications. Capable of fine grinding between 30-500µ, the easy-clean design is hygienic and available with a variety of grinding media and discharge options. Mills are available in stainless steel with a variety of finishes including bead blast or mirror finish. Kemutec, Bristol, PA 215-788-8013 www.KemutecUSA.com

Click to enlarge

Continuous Processing AttritorThe C Series continuous attritor is a “work-horse” machine that uses 1/8- 3/8-in. grinding media. The C-20 is designed for applications that require continuous production of large quantities of material. It is a low-maintenance, high-efficiency mill designed for processing ceramics, paints, coatings, chocolates, agricultural products, metal oxides, etc. The mill has been engineered with a “swivel head” that allows for easy access to the top of the grinding chamber. It also comes equipped with a 60-hp variable-frequency drive, tangential inlet assembly, media charging port, and media discharge plug. Union Process Inc., Akron, OH 330-929-3333 www.unionprocess.com

Click to enlarge

Lump ReducerThe LumpMaster reduces lumps and agglomerations in sugars, sludge cake, plastics, solid waste, or most other materials that compact. The simple and economical design is easily integrated into existing processes or can be engineered into a new feeding solution. Construction options are available for washdown or explosion-proof applications. Hapman, Kalamazoo, MI 800-427-6260 www.hapman.com

Click to enlarge

Hammer MillThe Model 4260 (42 x 60 in.) hammer mill features a two-stage reduction principle with a rain of hammer or ring blows that shatter and disintegrate the material. The materials are shattered two ways before passing through the grinding plate, 1) upon entry by the revolving hammers and 2) further disintegrated by forceful impact against the heavy breaker plates in the cover. The shredder-type hammers have six turns and Tungsten overlay on the cutting edge for extended life and lower operating cost. The size of the finished product can depend on the size of the openings in the perforated screens or spacing between the heavy-duty grates; the number, size, and type of hammers and rings, the setting of the adjustable grinding plate, and the rotor speed. The rotor construction is determined by the material to be reduced. Stedman, Aurora, IN 800-262-5401 www.stedman-machine.com

Click to enlarge

Single and Dual Rotor CrushersSingle and dual rotor crushers have been successfully applied to complement pneumatic conveying and bulk handling system installations in the dairy, food, chemical, pharmaceutical and agricultural industries. Many times the initial product characteristics or process can change, thus producing an agglomerated and harder material that is larger than the original material. If these larger pieces and agglomerations are not pre-conditioned through size reduction equipment, they can cause material drop out in the horizontal conveying lines. The proper selection of the size reduction equipment to pre-condition the material prior to the pneumatic conveying system will insure that you will not have any reduction in conveying performance or plugged lines. Machine and Process Design Inc., Anoka, MN 877-224-0653 www.mpd-inc.com

Click to enlarge

Air-Swept Pulverizer/ClassifierVersatility, energy savings, and one-step processing are key features of the Pulvocron. This air-swept pulverizer/classifier dries and grinds wet cakes, pastes, slurries, and produces free-flowing powders. It can also be used to dry non-aqueous volatiles. The unit is best suited for applications requiring moderate moisture reduction and size reduction. Process air can be heated up to 1200°F using gas, oil, or steam. It has a small footprint and internal components are easy to access for cleaning and maintenance. Bepex International, Minneapolis, MN 612-627-1415 www.bepex.com

You May Also Like