June 4, 2010

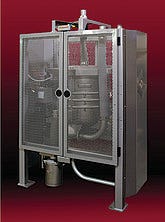

Rugged Separator

Rugged Separator

The MX is a new generation separator with design features to increase safety, provide a stronger construction, and allow for a more sanitary process. The totally enclosed weight guard prevents “reach-in” injuries, complying with CE Standards. Making use of the appropriate motor, the MX also complies with ATEX Standards. Angled support springs minimize aggressive vibration that typically occurs during shutdown of the machine. The extremely rugged construction of the MX utilizes conical construction rather than flat plates creating a more rigid geometric structure. The open-base construction allows for cleaning underneath the unit, preventing dirt and product buildup. Additionally, the MX base design eliminates all gussets and external crevices where product can become trapped while allowing for total external polishing of the machine. Sweco, Florence, KY 859-283-8400 www.sweco.com

Centrifugal Sifter

Centrifugal Sifter

Engineered to meet high-capacity sifting for bulk load-in/load out and larger process applications, the Rota-Sieve handles a wide variety of powder, granules, agglomerates, and other free-flowing materials. The combination of high-centrifugal force and blade-spreading action reduces binding problems, even when handling materials that tend to flake or agglomerate due to fat and moisture content. The unit can not only be used for sifting, scalping, and classifying, but may also remove foreign material, such as plastic and string. Prater-Sterling, Bolingbrook, IL 630-759-9595 www.prater-sterling.com

Circular Unitized Gyratory Screen

Circular Unitized Gyratory Screen

The Vibroscreen is a large circular unitized gyratory screen with three-component multiplane mechanical vibration. The motion is through a motor with a double extended shaft, fitted at both ends with eccentric weights. The whole drive assembly is mounted on a circular base by rugged springs that allow the unit to vibrate freely, and at the same time, the springs prevent transmitted vibration from reaching the floor area on which the machine stands. Screens can be mounted one on top of the other within the screening assembly. The unit is suitable for virtually any type of screening operation. (Pennwalt LTD) Heinkel USA, Swedesboro, NJ 856-467-3399 www.heinkelusa.com

Compact Screener

Compact Screener

The Megatex XD screener delivers accurate screening performance in a compact footprint. The unit is ideal for a wide range of screening processes, including agriculture, plastics, and chemical applications. An elliptical linear motion provides efficient screening performance with less downtime and lower energy consumption. The unit provides 25–50% greater capacity per square foot of screen cloth. The elliptical-linear motion—generated by an external drive cartridge—separates from ¼ in. to 100 mesh (6.3mm to 150µm). The screener requires minimal maintenance. Single screen deck changes take no more than 10 minutes; all screen decks can be changed in just two hours. Powered by a single 15- or 20-hp motor, the unit maximizes energy. Rotex Global LLC, Cincinnati, OH 800-453-2321 www.rotex.com

Rectangular Screening Machines

Rectangular Screening Machines

ScreenX rectangular screeners are based on a unique multi-frequency adapter that converts vibratory technology to impart high amplitudes/high energy directly to the screen surface. This energy pattern prevents blinding and stratifies the material across the screen surface to provide significant separation performance improvement. The Virto ScreenX 2.3x1 and ScreenX 2.8x1 rectangular machines excel on minerals, building materials, mining, and chemical applications. The equipment can operate at a rate of 3 to 12 times greater than standard vibratory screeners. Efficiencies of 95% and greater are achieved in a single pass, resulting in higher product yield and better undersize removal. Capital expense is automatically lowered because less equipment is needed to achieve greater results. Virto/Elcan Industries, Mamaroneck, NY 800-283-5226 www.virto-elcan.com

Click to enlarge

Compact In-Line Sifter/ScreenerThe QA24 in-line pneumatic sifter/screener has been developed to answer the quality assurance and HACCP needs of pharmaceutical, chemical, and food operations with moderate production requirements. Manufactured with a higher level of sanitation in mind, the QA24 has smooth surfaces with fewer weldments and snap-on neoprene gaskets that do not use adhesives. It has a net screen area from 4 to 10 sq ft and is ideal for dry free-flowing powders. It is designed to be directly inserted into a vacuum or pressure pneumatic conveying system, eliminating the need for additional equipment. Great Western Mfg. Company, Inc., Leavenworth, KS 800-682-3121 www.gwmfg.com

Drawer Magnets

Drawer Magnets

Continuous-cleaning HF drawer magnets can be used in any gravity-flow application in which continuous flow of product is required. They are ideal for operations that run 24/7 because they never need to be stopped to clean. They clean on the fly with no disruption of product flow and keep the operation going by: saving labor costs—no downtime needed; keeping product moving—self-cleans while product is still flowing; providing security—magnetic protection during entire process; and making installation easy—can be used in hard-to-reach locations. Bunting Magnetics Co., Newton, KS 316-284-2020 www.buntingmagnetics.com

Drawer Magnet

Drawer Magnet

The Round Spout Drawer Magnet (RSDM) removes small to medium ferrous tramp metal contaminants from dry, granular, free-flowing product streams in round gravity-fed vertical chutes and spouts. Unlike traditional drawer magnets, the RSDM can be attached directly to a pipe, eliminating the need to purchase and install mounting transitions or flanges. Available in 4- to 12-in. diam, it protects processing equipment and provides greater product purity. Ideal for sifter and screener discharge spouts, the standard RSDM boasts single or double magnet tiers to provide greater protection. Custom units with more magnet tiers are available. Magnetic Products Inc., Highland, MI 800-544-5930 www.mpimagnet.com

Air Classifiers

Air Classifiers

These air classifiers balance the physical principles of centrifugal force, drag force, and gravity to generate a high-precision method of classifying particles according to size and density. They meet cutpoints that are too fine for screens (200-400 mesh or finer). Other features include: continuous-duty avoids downtime from screen blinding; superior wear protection avoids downtime from screen wear/breakage; easy speed control adjustability to meet various product specifications; high capacity up to 800 tph (too large for screens); Whirlwind internal fan air classifier for fineness of 100 to 400 mesh; side-draft external fan air classifier for fineness of 100 to 400 mesh; and a super-fine external fan air classifier for fineness of 44 to 5 μm. These classifiers process aggregates, ceramics, chemicals, fly ash, foods, minerals, metals, plastics, and other materials. Sturtevant Inc., Hanover, MA 800-992-0209 www.sturtevantinc.com

High-Speed Two-Bearing Vibrating Screen

High-Speed Two-Bearing Vibrating Screen

The Overstrom high-speed two-bearing vibrating screen has adjustable-unbalance flywheels and a V–belt drive to allow speed changing. The flywheels can be set for peak efficiency amplitude, which increases with feed rate and aperture size. Changes in amplitude call for changes in rpm in inverse proportion to the square root of the amplitude change, to keep the centrifugal force within a safe operating range of 4-6 g. This versatile design for dry or wet screening is offered in screen sizes ranging from 2×4 ft to 10×24 ft, in one to three decks, and with two types of optional dust enclosures. Triple/S Dynamics, Dallas, TX 800-527-2116 www.sssdynamics.com

Manual Clean Drawer Magnet

Manual Clean Drawer Magnet

Engineered to remove medium and fine ferrous contaminants from dry, free-flowing products under gravity flow, this drawer magnet protects processing machinery and improves product purity. Multiple staggered rows provide maximum contact area for product flow. As product flows through the stainless-steel housing, it cascades over the staggered rows of magnetic tubes. Ferrous contaminants are pulled to the surface of the magnets where they move to the underside of the tube to prevent wash-off. EZ Clean and POW-R Clean options are also available for simplified cleaning. Puritan Magnetics, Oxford, MI 800-787-3624 www.puritanmagnetics.com

Stacked Deck Sifter

Stacked Deck Sifter

This stacked deck sifter allows quick screen changeouts. Whether a screen needs replacement due to a tear in the screen cloth, a change in mesh specifications, or when switching from one product to another, the CS-1 gyratory sifter saves time and labor. With the use of only standard hand tools, screen inserts can easily be changed within minutes. No noxious glue, drying time, or tensioning machine is required to replace the screens. The unit provides from 2 to 4 separations of dry product from ¼ in. in size down to 400 mesh with a capacity of 50,000 lb/hr. Sifter Parts & Service Inc., Wesley Chapel, FL 800-367-3591 www.sifterparts.com

Compact Sifters

Compact Sifters

The S10 is designed for small batch operations, while the S30 is designed for larger batch/continuous flow operations. With the addition of these two models, the FlexSift line can now handle up to 110,000 lb/hr, depending on the product being screened. The high-capacity, compact designs are easily vertically integrated into processes and overcome many of the typical problematic product flow bottlenecks associated with traditional sifting technologies. The FlexSift security screens, delumps, and discharges, all without the need for a product feeder, thereby allowing for higher capacities and better product flow than large conventional sifters. The unit is safe and simple to disassemble and has a minimal number of parts, enabling easier cleanup, quicker screen maintenance, and minimal down-time. Quadro Engineering Corp., Waterloo, ON, Canada 519-884-9660 www.quadro.com

High-Capacity Screener

High-Capacity Screener

This vibratory screener that discharges oversize particles 360° around the periphery of a circular screening deck increases capacity, improves efficiency, minimizes screen blinding, and prolongs screen life. The 60-in.-diam Vibroscreen model with External Kascade deck screens wet or dry bulk materials containing a large percentage of oversize fractions, at higher rates than attainable with conventional screeners. On-size particles pass through the screen and funnel through a lower discharge chute. Oversize particles flow outward in a spiral pattern and cascade at any point over the periphery of the circular screen onto a spiral vibratory trough that directs the material into a high-capacity discharge spout. The screening deck is offered on any of the company’s Vibroscreen separators from 40 to 72 in. in diam, and is available as a retrofit kit for any make of circular vibratory screener. Kason Corp., Millburn, NJ 973-467-8140 www.kason.com

Gravity Metal Detector

Gravity Metal Detector

Powder, dry, or granular free-flowing products are gravity fed through a pipe into the Phantom gravity metal detector. Designed to detect the smallest metal contamination, systems are available in aluminum or stainless-steel casings, with a selection of pipe sizes. Fortress Technology Inc., Scarborough, ON, Canada 416-754-2898 www.fortresstechnology.com

Ultrasonic Screening System

Ultrasonic Screening System

W.S. Tyler now offers the Haver ultrasonic screening system that uses sound waves to increase the throughput and screening efficiency of fine dry particles. This ultrasonic screening process uses a generator (included) to convert electrical energy into high-frequency pulses, which is then converted to sound waves. The sound waves create an oscillation in the screen frame at high frequencies. These oscillations are transferred to a screening cloth where they are evenly distributed across the entire surface. The oscillations reduce frictional resistance between material and screening media, thus creating a reduction in blinding and increased throughput and efficiencies. W.S. Tyler, Mentor, OH 800-321-6188 www.wstyler.com

Continuous-Cleaning Drawer-in-Housing

Continuous-Cleaning Drawer-in-Housing

This continuous-clean, magnetic drawer-in-housing is designed for ferrous metal separation in dry processing systems. It is ideal for remote magnet installation locations, applications requiring frequent cleaning, and fully automated processing systems. Magnetic tubes are aligned on alternating centers for multiple row drawer configurations, forcing the product flow in a zigzag pattern while contacting the magnetic tubes. The cascade effect ensures maximum tramp metal separation by causing product to have repeated and intimate contact with magnetic tubes and ensuring maximum capture of contaminants. The cleaning process is continuous and does not require the product flow to be stopped. The cleaning cycle is completed in a matter of seconds. Industrial Magnetics Inc., Boyne City, MI 800-662-4638 www.magnetics.com

You May Also Like