September 14, 2010

Vibratory Conveyor Monitoring System

Vibratory Conveyor Monitoring System

SmartArm is a wireless performance monitoring system for Iso-Flo vibratory conveyors that enables users to monitor asset or equipment shaker condition at any computer workstation. The system measures and reports speed and stroke to provide real-time analysis of shaker function, line-flow conditions, and trends at-a-glance. The SmartArm client also shows an alert when speed or stroke are out of tolerance. Empowering the shift from traditional time-based preventive maintenance to condition-based predictive maintenance, SmartArm not only prevents downtime and reduces labor, it also provides the opportunity to improve process efficiencies. Key Technology Inc., Walla Walla, WA 509-529-2161 www.key.net

Click to enlarge

Flexible Screw ConveyorThis Helix flexible screw conveyor is specifically designed to ensure food safety when processing sluggish powder and bulk solid ingredients. The Helix Hi/Lo flexible screw conveyor now features an optional mass-flow hopper that encourages discharge of sluggish or non-free flowing ingredients without the need for separate in-hopper agitation. The hopper’s steep, conical shape successfully moves challenging materials, such as those with high moisture or fat content. Optional external vibration can be added to assist with material flow. The mass-flow hopper eliminates the need to use an agitator, which utilizes seals that require a good deal of attention to clean. The design allows a single worker to safely and easily handle washdowns, auger changeouts, and servicing from floor level. An electric actuator automatically lowers the auger to an easy-to-access height. Exclusive T-handle couplings allow disassembly in minutes. Hapman, Kalamazoo, MI 269-382-8228 www.hapman.com

Multiple-Conveyor System

Multiple-Conveyor System

Multiple mechanical conveying methods are integrated into this automated bulk material handling system to move highly fibrous, non free-flowing material from infeed to discharge, from material conditioning to supply metering, and from metering to downstream processing. At infeed, a chain-driven live roller conveyor and an integrated, 3000-lb-capacity pop-up chain transfer conveyor move gaylords into position for automatic alignment with the gaylord dumper lift carriage. From the material conditioning stage, a 2500-lb/hr feed rate, continuous-duty weigh belt conveyor ensures accurate, reliable material supply. From material weighing an inclined, boxed-cleat belt conveyor delivers material to downstream processes at a final drive speed of up to 30 ft/min. National Bulk Equipment Inc., Holland, MI 616-399-2220 www.nbe-inc.com

Click to enlarge

Low-Maintenance Vibratory ConveyorThe Tex-Flex excited base vibratory conveyor utilizes a single maintenance-free rotary electric vibrator. It is mounted to an isolated conveyor frame to energize the leaf springs supporting the conveyor pan to produce the maximum conveying action with minimal power requirements. For most applications, the power requirement is less than 1 HP. The rotary electric vibrator is inverter driven allowing easy adjustment of conveyor speed and has adjustable eccentric weights allowing the force output and resulting conveyor stroke to be easily changed in the field to optimize conveying efficiency. Triple/S Dynamics, Dallas, TX 214-828-8604 www.sssdynamics.com

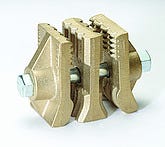

Non-Sparking Belt Splice

Non-Sparking Belt Splice

The Tapco-Splice NS is a bronze non-sparking belt splice designed to accompany the company’s existing zinc-plated Dura-Splice. This style of clamp splice holds belts in a vice-like grip, putting an end to the double belt thickness common to other splicing systems. Unique teeth at the top of the clamp provide extra gripping power. The non-sparking Tapco-Splice NS fits all pulley diameters and is recommended for belts rated up to 800PIW. It is supplied with a 4 ½-in. Grade 5 hex head bolt, accompanied by a Grade 8 hex compression nut, along with a self-adhesive template for creating the bolt holes in the belt. Tapco Inc., St. Louis, MO 800-288-2726 www.tapcoinc.com

Click to enlarge

Screw ConveyorsThese screw conveyors withstand harsh materials and unforgiving environments. They move virtually any dry, granular, or powdery material, even abrasive substances like fly ash, coal, coke, volcanic cinders, diatomaceous earth, and pebble lime smoothly and uniformly without packing or jamming. Long, unsupported screws eliminate the need for congestion-causing hangers. Products include screws with variable pitch, tapered flights, cut flights, mixing paddles, and ribbon screws. Screws are manufactured to any specified size using commercially available materials. Precision Machine & Manufacturing, Eugene, OR 800-722-9841 www.premach.com

Vibrating Transfer Conveyors

Vibrating Transfer Conveyors

These vibratory conveyors are ideal for moving a wide range of free-flowing materials in food and chemical processing. The natural frequency conveyor design uses less energy while efficiently moving material. Economical, low-hp motorized drive and FRP leaf springs are energy efficient and easy to maintain. An isolated base with coil springs results in low dynamic reaction. Standard designs are easily customized to meet your application requirements. General Kinematics Corp., Crystal Lake, IL 815-455-3222 www.gkprocess.com

Click to enlarge

Tilt-Down Portable Bulk ConveyorThis bulk conveyor with a tilt-down portable base fits through tight spaces and provides easy access for removal of the flexible screw. Its reduced footprint enables the caster-mounted frame to maneuver through narrow aisles and around corners. With the hopper, support boom, and conveyor assembly tilted down, the unit fits through standard doorways and orients the conveyor tube horizontally, allowing the flexible screw to be removed easily for thorough cleaning and inspection. Each unit is custom configured according to the discharge height, tilt-down height, discharge overhang, and overall size parameters of individual applications. The hopper, which is equipped with a hinged lid, feeds a flexible screw conveyor that transports bulk ingredients ranging from sub-micron powders to large pellets. The enclosed conveyor tube prevents product and plant contamination, while the gentle rolling action of material being conveyed prevents the separation of blends. The rugged inner screw is the only moving part contacting material, resulting in reduced maintenance and increased reliability. Flexicon Corp., Bethlehem, PA 888-353-9426 www.flexicon.com

Flexible Screw Conveyor

Flexible Screw Conveyor

The Aero-Flex flexible screw conveyor provides an economic method of metering product from bulk bag unloaders, bag dump stations, and storage vessels. Available in a range of popular sizes the unit transfers powders over distances of up to 40 ft and rates to 10 tn/hr. Vac-U-Max, Belleville, NJ 800-822-8629 www.vac-u-max.com

Click to enlarge

Tube ConveyorsThis complete line of vibrating tube conveyors moves virtually any bulk material without internal parts to wear or break. The machines are available in capacities up to 300 cu ft/hr, with single unit lengths up to 25 ft. They can be linked together for longer conveying distances and are available in carbon and stainless steel, with finishes to meet virtually any sanitary specification. Optional controls provide a 5:1 feed range and, when connected to a bin activator or bulk bag unloader, feed accuracies of ±2-3% are possible for most materials. The conveyors also have the ability to handle fragile particles without degradation. A flexible connection at either end makes the machines entirely dust-tight. Vibra Screw, Totowa, NJ 973-256-7410 www.vibrascrew.com

Aero-Mechanical Conveyor

Aero-Mechanical Conveyor

This aero-mechanical conveyor is designed for high throughput of semi free-flowing powders like Talc, TiO2, and carbon black. The unit can convey up to 18 cu ft/min and is ideal for bulk bag unloading and loading, conveying powders quickly to process vessels, and reloading feeders. Features include clean-in-place housings, independent tensioning, and flood feed inlets. The unique properties of a combination of fluidized and mechanically assisted conveying enables high transfer rates at low levels of power. Aerocon, Belleville, NJ 800-405-2376 www.aeromechanical.com

Click to enlarge

U-Trough and Tubular Screw ConveyorsThese screw conveyors provide efficient and reliable service to suit any demanding industrial application especially for food, cosmetic, biotech, and pharmaceutical processes. The conveyors are available in conventional U-trough and tubular designs. In addition, the exclusive split-tubular design offers several features and benefits that facilitate operation and maintenance procedures. The hinged, gasketed, and tubular cover offers the material confinement of a conventional conveyor, with the added benefit of easy cleaning and inspection of the auger. Batch processing is facilitated where there is the need to eliminate cross contamination and removal of any residual material from a prior batch. S. Howes Inc., Silver Creek, NY 716-934-2611 www.showes.com

Bulk, Package, and Pallet Conveyors

Bulk, Package, and Pallet Conveyors

Multiple standard conveyor designs include flat and troughed, slider and roller bed frames. Belting with smooth or patterned surfaces is utilized for horizontal and incline applications, corrugated sidewall belts for steep incline applications, and flat wire and powered rollers for bag and pallet applications. Chantland-MHS, Humboldt, IA 515-332-4045 www.chantland.com

Click to enlarge

Flexible Screw and Vibratory Tube ConveyorsConvey-All/FSC flexible screw and vibratory tube conveyors provide economical, yet effective, conveying of dry bulk solids materials. They feature a rugged design with only one moving part for ease of maintenance and cleaning, are available in 10- to 20-ft lengths, and offer a choice of a 3-in.-diam helix screw that nominally conveys up to 150 cu ft/hr or a 4-in-diam helix screw that conveys up to 450 cu ft/hr. They have only two moving parts for long-lasting operation with low-power consumption, are available in 4- to 10 ft-lengths with 6- to 10-in.-diam tubes, and convey high rates of difficult flowing or friable dry solids up to 400 cu ft/hr. Metalfab Inc., Vernon, NJ 800-764-2999 www.metalfabinc.com

You May Also Like