April 1, 2010

Ho rizontal Motion Conveyor

rizontal Motion Conveyor

Providing gentle, linear conveying of even the most fragile food products and powders, the X-Force horizontal motion conveyor is capable of transferring material up to 200 ft with a single drive. Like the Slipstick, the X-Force employs a slow advance, quick-return conveying action that makes it ideal for flakes, blended materials, and coated products. In addition, it reduces material damage, coating loss, segregation, and stratification. Buildup of oily fines or sticky materials is also greatly reduced. All models feature full-length hinged covers and are equipped with smooth, sanitary surfaces and large radius corners for ease of cleaning. Troughs with multiple lanes are available to simultaneously transfer more than one product. These troughs can be aluminum, stainless steel, or application-specific polymer or composite materials. Triple/S Dynamics, Dallas, TX 800-527-2116 www.sssdynamics.com

T rough Slider-Bed Belt Conveyors

rough Slider-Bed Belt Conveyors

Booth 1837 - These trough slider-bed belt conveyors use an open-center concave pan section and a variety of belt sizes to quickly move large volumes of bulk material. A choice of smooth belt and textured cleat topped belts are available. The motor is mounted on the side of the conveyor section. Adding options such as in-feed hoppers, spouts, spout extensions, diverters, plow-offs, belt wipers, incline and decline elbows, and covers to the basic unit increases versatility. These conveyors are ideal for when your operations needs to: move grains, sawdust, forages, chips, and many other bulky materials; move material where you want with one-way or directional conveying, adjustable elbow or straight-line conveying, and plow-off; move material at your choice of belt speeds; and have the option of any length of conveyor from 4 to 200 ft. Bunting Magnetics Co., Newton, KS 316-284-2020 www.buntingmagnetics.com

Conveyors and Bulk Handling Systems

Booth 3533 - Along with PosiPortion feeders, Helix flexible screw conveyors and the company’s tubular drag conveyors can be combined with bag dump, bulk bag handling, and general industrial processing equipment to engineer complete weigh/batch systems. A wide range of performance options are also available to assist in enhancing processing rates and accuracy. Hapman, Kalamazoo, MI 800-427-6260 www.hapman.com

B ulk Material Handling Systems

ulk Material Handling Systems

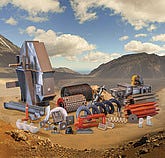

Martin offers standard bulk material handling equipment and custom systems and components. Units are supplied for just about every segment of the industry with fast delivery to avoid costly downtime. Available components include: CEMA standard screws; shaftless screws; drag conveyors; bucket elevators; large flights up to 10 ft in diameter and 1½ in. thick; cone screws; ribbon screws; self-lubricating hard iron bearings; and more. Martin Sprocket & Gear Inc., Arlington, TX 817-258-3000 www.martinsprocket.com

F lexible Screw and Vibratory Tube Conveyors

lexible Screw and Vibratory Tube Conveyors

Convey-All/FSC flexible screw conveyors feature a rugged design with only one moving part for ease of maintenance and cleaning, are available in 10- to 20-ft lengths, and offer a choice of a 3-in-diam helix screw that nominally conveys up to 150 cu ft/hr or a 4-in.-diam helix screw that conveys up to 450 cu ft/hr. These conveyors have only two moving parts for long-lasting operation with low power consumption, are available in 4- to 10-ft lengths with 6- to 10-in. diam tubes, and convey high rates of difficult flowing or friable dry solids up to 400 cu ft/hr. Both conveyors are specifically designed and engineered to provide flexibility to accommodate other Metalfab up or downstream equipment such as bin activators, bulk bag unloaders, Posibins, feeders, and hoppers. Metalfab Inc., Vernon, NJ 800-764-2999 www.metalfabinc.com

Heavy-Duty Aeromechanical Conveyor

Heavy-duty TransVair mechanical conveyors are manufactured for users who need to operate 24 hours/day and require up to 100 psig internal pressure rating for handing explosive products. The TMC is dust- and gas-tight, using a patented o-ring tube seal design, outboard greasable bearings, triple lip seals on sprocket shafts, optional lantern ring, and purge and hand wheel operated rope tensioner for quick tensioning. These conveyors use standard MAX-LIFE ropes that are available from stock. Young Industries Inc., Muncy, PA 800-546-3165 www.younginds.com

FDA-Compliant Nylon Elevator Buckets

Booth 1327 – These new Nylon elevator buckets comply with FDA Regulations Title 21 CFR177.1500, CFR175.105, CFR178.2010, and CFR 177.300. The polyethylene buckets already meet stringent FDA standards under Food Additives Law and Regulations Nos. 175.300 and 177.2600. FDA-compliant urethane buckets are also available. All FDA-compliant buckets are molded from engineered resins that will not leach into or affect the integrity of ingredients used for food products to maintain optimum quality control. Tapco Inc., St. Louis, MO 800-288-2726 www.tapcoinc.com

F lexible Screw Conveyor

lexible Screw Conveyor

Booth 1737 – This flexible screw conveyor is an economical method of conveying product from bulk bag unloaders, bag dump stations, and storage vessels. Available in a range of sizes, the conveyor typically transfers product over distances of up to 40 ft and rates to 10 tn/hr for materials having a bulk density of 40 lb/cu ft. Typical applications include the refilling of packaging machine hoppers, metered feed into mix tanks such as lime addition, and gain-in-weight hopper filling. Vac-U-Max, Belleville, NJ 800-822-8629 www.vac-u-max.com

Buc ket, Belt, and Vibrating Conveying Systems

ket, Belt, and Vibrating Conveying Systems

This company offers a wide range of mechanical conveying systems that include a wide variety of bucket, belt, and vibrating conveying systems. A standard range of conveying systems is available, as well as custom-designed units that suit specific applications. Systems are supplied for applications across the food, mineral, and chemical industries. Pictured is a small vibratory feeder that feeds a specialized mini-loop bucket conveyor. Gough-Econ, Charlotte, NC 800-264-6844 www.goughecon.com

S anitary Feeder-Conveyor

anitary Feeder-Conveyor

Booth 1005 - This combination feeder-conveyor for free-flowing and non-free-flowing bulk dairy products, pharmaceutical products, and other contamination-sensitive materials meets 3-A sanitary standards. A coupling positioned beyond the point at which material exits the discharge spout eliminates the potential of contamination while allowing quick disconnection of the screw from the motor drive for washdown. The screw is the only moving part contacting material. Flexicon Corp., Bethlehem, PA 888-353-9426 www.flexicon.com

Tu be Conveyors

be Conveyors

Booth 3725 - This complete line of vibrating tube conveyors moves virtually any bulk material without internal parts to wear or break. The machines are available in capacities up to 300 cu ft/hr, with single unit lengths up to 25 ft. They can be linked together for longer conveying distances and are available in carbon and stainless steel, with finishes to meet virtually any sanitary specification. Optional controls provide a 5:1 feed range and, when connected to a bin activator or bulk bag unloader, feed accuracies of ±2–3% are possible for most materials. A flexible connection at either end makes the machines entirely dust-tight. Vibra Screw, Totowa, NJ 973-256-7410 www.vibrascrew.com

Lu mp Breaker

mp Breaker

Booth 2814 - The Delumper crusher 1077L is a precision designed unit that reduces lumps and agglomerates to desired output with a positive once through chopping action. This unit employs a smooth rotating drum mounted with replaceable teeth that intermesh with special sizing combs. It easily processes a wide range of solids, reducing them to their basic grain size without fines, overgrind, or heat-rise. These materials include chemicals, minerals, plastics, pharmaceuticals, and more. The unit offers smooth operation, low noise and vibration, easy assembly, and long service. It features one-piece, dust-tight body construction, smooth polished seamless body individually replaceable teeth, shaft seals, connecting flanges, and a low-headroom design. Sanitary design and finish, special alloys, and outboard bearings with packing seals, as well as secondary sizing screens, are available. Franklin Miller Inc., Livingston, NJ 973-535-9200 www.franklinmiller.com

Bulk Bag Disc harging System

harging System

Booth 3917 – The modular Material Master bulk bag discharging system offers patented technology and features that maximize production efficiency. A Sure-Seal pneumatically actuated discharge spout clamping system and pulse-jet dust collection system ensure dust-tight operation, while a Flo-Master bag massaging system and high-deflection vibratory feeder with variable speed controls provide reliable metering of low bulk density powders. The pulse-jet dust collection system returns collected material back into the product stream, eliminating waste. The system is designed for Div. 2 service; product contact surfaces are Type 304 stainless steel. Systems are custom designed for specific application requirements. Material Transfer and Storage, Allegan, MI 800-836-7068 www.materialtransfer.com

Arch Breaker

Booth 2702 - This arch breaker features a vertical spindle fitted with flexible blades to ensure the mechanical agitation and discharge of dry solid materials from silos, bins, or hoppers, while preventing the bulk material from jamming, bridging, compacting, or rat-holing caused by vibration or fluidization. The mechanical arch breaker not only gently and efficiently discharges bulk products, but integrates 1, 2, 3, or 4 precise volumetric screw feeders. Each screw feeder is totally independent and can feed up to 15,000 lb/hr with different length and throughput variations. Lime, powder activated carbon, soda ash, and potassium permanganate are among the dry chemicals handled by this silo discharger. The arch breaker is adapted for bin activator or fluidization systems retrofit. Sodimate Inc., Chicago, IL 773-665-8800 www.sodimate-inc.com

Level Indicator with Universal Power Supply

Booth 2407 - The VibraRod vibratory type bin/silo sensor is a point level indicator that can be used in a wide variety of applications. It is ideal as a high-level indicator for bulk solids as low as 3.12 lb/cu ft with a maximum particle size of 3/8 in. The ordinary location VibraRod point level sensor now has a universal power supply (20-255V ac/dc). This allows customers with various power supply requirements to specify a single part number for all of their voltage requirements. Another useful feature is the single-element probe design that helps eliminate false signals that can exist when material builds up between the tines of “tuning fork” style probes. Monitor Technologies LLC, Elburn, IL 800-766-6486 www.monitortech.com

R ectangular Screeners

ectangular Screeners

Booth 1336 - ScreenX rectangular machines are based on a multi-frequency adapter that converts vibratory technology to impart high-amplitudes/high-energy directly to the screen surface. This energy pattern prevents blinding and stratifies the material across the screen surface to provide significant separation performance improvement. The Virto ScreenX 2.3x1 and ScreenX 2.8x1 rectangular machines are ideal for minerals, building materials, mining, and chemical applications. The equipment usually operates at a rate of 3 to 12 times greater than standard vibratory screeners. Efficiencies of 95% and greater can be achieved in a single pass. Virto/Elcan Industries, Mamaroneck, NY 800-283-5226 www.virto-elcan.com

V olumetric/Gravimetric Feeder

olumetric/Gravimetric Feeder

Booth 1637 - Designed specifically for low feed rate applications, the PureFeed AI-300 feeder includes the following customer driven features: quick and easy disassembly, a dual arm external agitation system for maximizing material handling versatility, and a disposable, recyclable EPDM feed hopper. That means simpler, shorter cleaning cycles and virtually no chance of cross contamination when moving from one dry bulk solids material to another. The unit also features a stepper motor that allows users to change the penetration agitation speed on the hopper of the feeder without making any mechanical adjustments. For customers who need to change materials frequently this feature allows them to do so without interrupting production accommodating the new material being fed. The feeder is available in volumetric and gravimetric configurations for applications such as metering micro ingredients, color pigments, and plastic additives in feed rates from 0.5 to approximately 150 kg/hr. Schenck AccuRate, Whitewater, WI 800-558-0184 www.accuratefeeders.com

Explosionproof Drum Discharging & Feeding System

Booth 3917 – This system safely inverts drums of dusty powders and then meters the material into an existing screener. The hydraulic Lift and Seal System seals the drum outlet to a dust-tight pour cone for a clean working environment. The patented Control Link rotation system provides 180° drum rotation for maximum product discharge. The stationary docking transition module supports the rotary valve feeder and tool-free flexible connection to screener inlet (screener not shown). All product contact surfaces are polished Type 304 stainless steel. Systems are custom designed to meet specific application requirements. Material Transfer and Storage, Allegan, MI 800-836-7068 www.materialtransfer.com

R emote Wireless Storage Monitor <

emote Wireless Storage Monitor <

Booth 2243 - BinMaster Level Controls and Digi International have collaborated on the development of the BinLink Web-based bin, tank, and silo monitoring solution. The solution enables remote wireless inventory management of stored material from any PC with Internet access. This saves customers time and money by eliminating the need for on-site remote bin level measurements. It also minimizes farm management mistakes that can lead to massive livestock losses due to increased visibility of bin/tank/silo information. The solution includes SmartBob2 and SmartBob-TS1 sensors mounted on the bins and a Digi Connectport X gateway running the SmartBob application to provide bin level measurement data that can be accessed easily via the Internet. BinMaster, Lincoln, NE 402-434-9100 www.binmaster.com

P article Size Analyzer

article Size Analyzer

Booth 3014 - Beckman Coulter has extended the range of its LS 13 320 particle size analyzer to allow high-resolution, reproducible measurement of samples from 0.017 to 2000 µm. The enhanced analyzer also adds Rosin-Rammler and Folk & Ward Phi methods to its full complement of standard analytical capabilities. The instrument’s patented Tornado Dry Powder Dispersing System keeps sample particles intact, allowing true measurement of the original samples. Reproducibility is typically better than one percent. These features combine with the extended size range to provide high-accuracy/high-resolution detection without the risk of missing either the largest or the smallest particles in a sample. Beckman Coulter Inc., Miami, FL 305-380-2314 www.coultercounter.com

C onveyor Seals

onveyor Seals

Booth 2630 – MECO HB model seals for standard-sized screw conveyors offer many of the features used in the company’s custom shaft seals, but are in stock in five CEMA and 11 metric shaft sizes, from 1 ½ to 3 7/16 in. and from 40 to 90mm. HB seals are designed to perform under 90% of the typical operating conditions associated with screw conveyors or scrolls, even where waste pack housings, packed glands, lip seals, or other seals fail. This includes food-grade applications, temperatures up to 500ºF, abrasive products, and vertical or inclined conveyor shafts. The HB accommodates up to ¼ in. of shaft run-out. Woodex Bearing Company, Inc., Georgetown, ME 800-526-8800 www.mecoseal.com

H igh-Speed Abort Gate

igh-Speed Abort Gate

Booth 2715 – This abort gate is an important part of any duct spark or leak detection system. An abort gate can be located prior to the inlet of a dust collection system to prevent a flame or burning ember from entering the dust collection system. This method is used if extinguishment from spark detection equipment is not adequate or not an option. Leak detection or broken bag sensors can activate the abort gate in the event of a filter failure. The abort gate can be placed on the return air side of the dust collector to redirect contaminated air to safe location. Standard features include: heavy-duty fully welded steel construction, painted OSHA safety yellow, 110-V control panel, manual gate reset by a hand-crank actuator, gate accelerating springs, fail-safe electro-magnets, steel gate seals, and limit switches for gate position indication. Imperial Systems Inc., Jackson Center, PA 800-918-3013 www.isystemsweb.com

Nozzle-Based Cleaning System

Booth 2603 – This company offers a complete line of baghouses and cartridges collectors with special design features that include a nozzle-based cleaning system that induces more cleaning air into the media. By improving the amount of cleaning air induced, the filter will last longer and allow more process air to pass through or recover better. A recent nozzle improvement induces even more cleaning air into the filter than before. In addition, certain nozzle types also allow the reverse pulse-jet system to operate at lower compressed air psi levels. In this proven technology the venturi at the top of the bag/cage is eliminated. This allows for a lower design and operating system pressure drop. Scientific Dust Collectors, Alsip, IL 708-597-7090 www.scientificdustcollectors.com

Co mpletely Enclosed Conveyor

mpletely Enclosed Conveyor

The Python conveyor can be installed in both a vertical and horizontal position and can be routed around obstructions with radius of turn as small as 10 ft. The conveyor is a dust-free system when transporting material by totally encasing the product. The Python tube inherits closing force when manufactured. There are no mechanical devices needed for closing the tube and for securing conveyed material in any position. An important quality control issue is checking stability of closing forces. The photo shows a special installation that is testing a ready-to-go tube sample for one million open/close cycles. For a 600-ft-long conveyor with a speed of 500 ft/min, one million openings/closings of the tube will be reached after more than 27 months, working 24/7, year-round. ATBC LLC, Park Ridge, IL 847-648-2822 www.python-conveyor.com

Vibratory Conveyor Monitoring System

The SmartArm is a wireless performance monitoring system for Iso-Flo vibratory conveyors that enables users to monitor asset or equipment shaker condition at any computer workstation. The system measures and reports speed and stroke to provide real-time analysis of shaker function, line-flow conditions, and trends at-a-glance. Empowering the shift from traditional time-based preventive maintenance to condition-based predictive maintenance, the system not only prevents downtime and reduces labor, it also provides the opportunity to improve process efficiencies. Key Technology Inc., Walla Walla, WA 509-529-2161 www.key.net

You May Also Like