November 6, 2007

Flexible-Screw Conveyor

Flexible-Screw Conveyor

This company is introducing the Rhinoveyor flexible-screw conveyor and the aeromechanical conveyor-tensioning device. The Rhinoveyor FSC is designed to convey even the most abrasive materials such as sintered metals, PFA, pumice, sand aggregates, silica, cement, and carborundum. The AMC automatic tensioning device eliminates the need for employees to check rope tension and prolongs the average life of AMC rope/disc assemblies by keeping them properly tensioned.

Spiroflow Systems, Monroe, NC 704-291-9595 www.spiroflowsystems.com

Gate Options for Horizontal Conveyors

Gate Options for Horizontal Conveyors

A variety of discharge gate options are available for the Slipstick horizontal-motion conveyor. The Plug Gate is designed for maximum sanitation and protection of the product stream from contamination. Designed for rugged use, the standard slide gate includes a UHMW gate plate that is retained by stainless-steel guide rails. Used to control the split of a product flow into multiple streams, the proportioning gate has adjustable presets that allow the proportions of each split to be adjusted during conveyor operation. The rail gate is used for handling products that tend to build residue on contacting surfaces or for environments where sticky or abrasive dust is present. The pinch-free gate is used for sticky products or for products that are vulnerable to damage in typical slide gates. The pivot gate offers maximum sealing security against dust leakage without the use of an elastomeric seal in the product zone.

Triple/S Dynamics, Dallas, TX 800-527-2116 www.sssdynamics.com

Sanitary Feeder-Conveyor

Sanitary Feeder-Conveyor

This combination feeder-conveyor for free-flowing and non-free-flowing bulk dairy products, pharmaceutical products, and other contamination-sensitive materials meets 3-A sanitary standards. A coupling positioned beyond the point at which material exits the discharge spout eliminates the potential of contamination while allowing quick disconnection of the screw from the motor drive for wash-down. The screw is the only moving part that contacts material. The unit simultaneously meters and elevates bulk materials, potentially eliminating the need for a separate feeder and conveyor while reducing the clearance typically required above the receiving vessel for a dedicated feeder. Mobile and high-capacity units are also available.

Flexicon Corp., Bethlehem, PA 888-353-9426 www.flexicon.com

Mechanical Conveying Systems

Mechanical Conveying Systems

This company designs and builds mechanical conveying systems that provide gentle handling of delicate, value-added products and move product through the production process with minimal loss, breakage, spillage, cleanup, and downtime. Its complete line of equipment includes bucket elevator and conveyor systems, vibratory feeders, belt conveyors, hoppers, and bulk bag loaders/unloaders.

Gough Econ Inc., Charlotte, NC 800-264-6844 www.goughecon.com

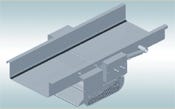

Intermediate-Drive Conveyor and Low-Profile Idler Assembly

Intermediate-Drive Conveyor and Low-Profile Idler Assembly

The intermediate-drive conveyor and low-profile idler assembly are versatile new options in the Designer System conveyor line. The intermediate-drive conveyor requires only a 26-in. straight section and allows gearmotor placement to be determined by customer preference. The low-profile idler, with its nose diameter of only 3½-in., can often eliminate the need for transfers, even for product sizes as small as 4 in. In conjunction with the intermediate drive, low-profile idlers may be used at both ends of the conveyor.

SpanTech LLC, Glasgow, KY 270-651-9166 www.spantechllc.com

Sliding Conveyor

Sliding Conveyor

The E-Z Slide conveyor is ideal for material-handling applications that require a smooth, sliding action. The conveyor’s positive sliding motion enables fragile products to move easily without the hopping and tumbling common to other conveyors or vibratory feeders. For example, food products are shuffled gently along without breakage. Coated parts move without disturbing coatings. The unit also features self-cleaning action, long conveyor lengths, a variety of trays, and low maintenance. It can be floor-mounted on pedestals or suspended overhead. The single drive unit may be located at either end or under the tray to fit any plant installation, even when space is limited. Controls are available to allow variable speed adjustment.

Eriez, Erie, PA 888-300-3743 www.eriez.com

Flexible-Screw Conveyor

Flexible-Screw Conveyor

The AFC Model #45K (knife-edge) 4½-in.-diam Spiralfeeder conveyor features stainless-steel material-contact construction, NEMA-4X controls, and factory prewired electricals. The unit incorporates an 8½-cu-ft-capacity True-Flow hopper, motorized agitation, and a low-level switch for automatic operation. Unique to this system is the integration of a Puritan EZ Clean vertical spout magnet assembly with inflatable drum-filling attachment.The system is portable and designed to handle difficult flowing material at rates in excess of 300 cu ft/hr.

Automated Flexible Conveyor Inc., Clifton, NJ 800-694-7271 www.afcsolutions.com

Aeromechanical Conveyors

Aeromechanical Conveyors

Powderflight aeromechanical conveyors provide high output, clean handling, and energy savings. They convey powders, granules, pellets, flakes, or flocks with minimal product degradation and no separation of blended material. Advantages include dust-tight conveying and complete batch transfer, no separation of blended products, minimal attrition of fragile particles, no filtration required at discharge, the ability to convey material at any angle between 0° and 90° without loss of capacity, low operating noise levels, and self-emptying that allows for conveying dedicated batches.

UniTrak Corp. Ltd, Port Hope, ON, Canada 905-885-8168 www.unitrak.com

You May Also Like