September 27, 2007

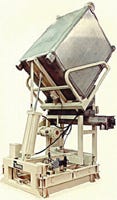

Drum Dumper with Volumetric Feeder

Drum Dumper with Volumetric Feeder

This system is designed to discharge and meter powders into the inlet of a conveying system or existing process. The exclusive Lift & Seal system hydraulically seals drums to a carbon steel pour cone for dust-tight and contaminant-free discharge. The unit features a 60° discharge angle, fluidizing pads, and a pneumatic vibrator to ensure material flow. Drum discharging systems are custom designed for specific application requirements.

Material Transfer & Storage Inc., Allegan, MI 800-836-7068 www.materialtransfer.com

Portable Lifting Platform

Portable Lifting Platform

The portable Lift-Tool is an economical alternative to variable-height workbenches. The simple yet versatile device facilitates a variety of lifting and positioning jobs and requires only a cordless drill to move the platform up or down. At a workbench, the unit helps improve the user’s posture, reducing fatigue and back strain and thus improving concentration and productivity. For a shift change at a shared workbench or simply to alternate between sitting and standing during repetitive-motion tasks, the platform can be quickly adjusted within a vertical range of 14¼ in. to accommodate the work at hand. Fully raised, the 22 × 23-in. platform is 17¾ in. high and is only 3½ in. high when lowered. With a load capacity of 300 lb, it holds nearly 10 times its own weight (32 lb).

Southworth Products Corp, Portland, ME 207-878-0700 www.SouthworthProducts.com

Radio Remote Control System

Radio Remote Control System

The MKU radio remote control system includes the Metal Keypad-U (MKU) operator control unit for industrial applications. With “full metal jacket” construction, the MKU is a radio remote control product that combines the robust design requirements of the North American market with European CE safety approvals. It employs sophisticated industrial-grade MIL-SPEC digital components protected by a thick-walled epoxy-coated extruded aluminum case. The ends of the housing are protected by rubberized metal-plated shock-absorbing end caps. The controller weighs 1.4 lb and also features sealed silicon elastomer switch types that are dust, water, oil, and acid resistant. They have a tactile feel and clear epoxy–coated dual-step push buttons.

Cattron Group International, Sharpsville, PA 724-962-3571 www.cattrongroup.com

Spur- and Worm-Gear Winches

Spur- and Worm-Gear Winches

These spur-gear and worm-gear hand winches are designed for manufacturers requiring confident load-lifting control and accurate load positioning and tensioning capabilities. Durably constructed, they have flexible lifting, pulling, and moving abilities, enabling them to perform a range of applications from lifting equipment for maintenance to positioning heavy molds during production processes. With a variety of models to choose from, the company offers both machine-cut single- and double-reduction spur-gear designs with capacities up to 10,000 lb and fully enclosed worm-gear designs with capacities up to 4000 lb. Most hand winch models are available with optional brakes for lifting and quick-disconnect anchors for quickly attaching or removing the wire rope. The winches also feature corrosion-resistant finishes, including enamel paint or zinc-plated finishes. They are even available in stainless steel for the most demanding conditions.

Thern Inc., Winona, MN 800-843-7648 www.thern.com

Pallet Dispenser

Pallet Dispenser

The Model 601 pallet dispenser features a side-clamp design that grips and lifts the entire stack of pallets to allow the bottom pallet to feed independently from the stack to the palletizing station. This design enhances palletizing efficiency, since it allows the dispenser to run pallets with protruding nails or loose boards while minimizing further pallet damage and eliminating handling concerns during warehousing and shipping. The side clamp is an improvement over traditional hydraulic dispensers that use a pusher ram to strip pallets from the bottom of the stack, which can cause additional damage to imperfect pallets. This compact, self-contained unit offers a solid steel frame with barrier guarding, a heavy-gauge chain-driven pallet handling mechanism, and motorized lift and clamp devices, providing 1000-lb lift capacity and a maximum 15-pallet load. Operation is automatic; up to three pallets per minute can be fed when a signal or command is given. The electric motor drive is controlled by an Allen-Bradley Micrologic PLC.

A-B-C Packaging Machine Corp., Tarpon Springs, FL 800-237-5975 www.abcpackaging.com

Loss-in-Weight Portable Bin Unloader

Loss-in-Weight Portable Bin Unloader

The design of this loss-in-weight portable bin unloader allows users to accurately discharge and meter material stored and transported in either side of a bin or to bottom-discharge portable bins. The system can be configured for either continuous loss-in-weight feeding or batch feeding. Weighing is done through a patented low deflection, nonwearing force measurement suspension system (FMSS) flexure scale that measures vertical loading and can take high-load directed overloads (1000%). The FMSS scale design uses counterweights to negate the tare weight of the support structure, feeder, and bin, resulting in the best possible weight signal.

Thayer Scale-Hyer Industries Inc., Pembroke, MA 781-826-8101 www.ThayerScale.com

You May Also Like