December 13, 2010

Particle Imaging and Analysis System

Particle Imaging and Analysis System

The latest FlowCAM particle imaging and analysis system integrates proprietary, new flow control software with an advanced syringe pump to replace manual sample handling and flow control setup with an automated process that enables the operator to load the sample, press start, and walk away while the sample runs unattended. Achieving sample volume efficiencies up to 90%, the unit delivers control over the flow rate and throughput volume to ensure that virtually the entire sample is properly presented to the flow cell for high accuracy in the real-time detection, imaging, counting, and measurement of particles and microorganisms. Fluid Imaging Technologies Inc., Yarmouth, ME 207-846-6100 www.fluidimaging.com

Click to enlarge

Rate Meter with System Slowdown TestThe TR400 rate meter — which displays an automated system’s production rate or time in process with high accuracy — now features a slowdown test to simply verify relay setpoints and operation. The system slowdown test allows users to periodically test setpoints while the system is functioning normally, with no system recalibration required after testing is complete. With the system slowdown test, there is no risk of losing setpoint values, saving costs and time. Once the test is activated, the TR400 gradually scales down the actual input frequency, simulating a slowdown while the system maintains normal running speed. Electro-Sensors Inc., Minnetonka, MN 800-328-6170 www.electro-sensors.com

Programmable Logic Controller

Programmable Logic Controller

Precise, efficient weighing is achieved through this programmable logic controller. The PLC is designed specifically to meet unique processes that can include varying batches, multiple feeders, etc.Complex processes are streamlined with pre-programmed routines. The filler is efficient for storing or incorporating material into an operation. Load cells mount onto the frame for weighing accuracy. Performance enhancement options include an adjustable frame, inflation/deaeration systems, and a hang weigh system. Hapman, Kalamazoo, MI 800-427-6260 www.hapman.com

Click to enlarge

Vibration Level MeasurementThe Rotalign ultra vibration acceptance check works in combination with the Vibtool vibration meter to measure vibration level according to ISO 10816-3 international standards. The RMS velocity value is wirelessly transferred and stored back onto a Rotalign Ultra computer where the result is instantly evaluated against the machine classification threshold. This fulfills the recommendation of the acceptance check after installation of rotating machinery or alignment job. Ludeca Inc., Doral, FL 305-591-8935 www.ludeca.com

Pill Feeder Package

Pill Feeder Package

The YTF02-LA pill feeder package is an automatic Statistical Process Control (SPC) solution that allows you to complete your capsule, pill, or tablet analysis while you perform other tasks - saving you time while also eliminating the risk of inherent errors in manual data recording. The variable vibration settings provide you with the flexibility to adjust for different size pills and capsules. The package also includes a printer that provides a configurable printout and the SPC program that produces sophisticated results according to USP guidelines. Sartorius Mechatronics Corp., Bohemia, NY 800-635-2906 www.sartorius-mechatronics.com

Click to enlarge

Custom-Built Automation and Control SystemsWhether machine communication is machine-to-machine or machine communication is through a central, supervisory control system, the custom-built controls and integrated automation ensure simplified equipment integration and streamlined system start-up. The systems are built to meet or exceed application-specific codes and regulatory standards, domestic or international. They push control functionality farther out and deeper into equipment operations to optimize total line throughput and deliver a system-wide data report from the control layer. National Bulk Equipment Inc., Holland, MI 616-399-2220 www.nbe-inc.com

Microwave Moisture Measurement

Microwave Moisture Measurement

M-Sens 2 is an online moisture meter designed for continuous monitoring of moisture in solids. It is housed in a high-grade stainless steel body with a ceramic face for abrasion resistance. It offers 0.1% accuracy of the calibrated measuring range. Up to three sensors can be connected to the electronics for obtaining a reliable reading in a large area. The sensor is typically mounted to the bottom of a chute or screw feeder or the top of a conveyor belt. GTS Inc., Shalimar, FL 850-651-3388 www.onthelevel.com

Click to enlarge

NIR Moisture AnalyzerOn-line NIR moisture measurement, using a sight window or insertion probe to view the product, enables continuous monitoring in fluidized bed dryers. The MCT 360 is a practical solution for controlling moisture content during granulation and during cycles. Benefits include consistent particle size distribution and bulk density from batch to batch and increased product yield. A reduction in energy and raw material usage will also be achieved through shorter granulation cycles. Increased efficiency will be realized through shorter drying cycles and a minimal delay between production batches. Process Sensors Corp., Milford, MA 508-473-9901 www.processsensors.com

Process Control Systems

Process Control Systems

BEST technologically advanced, fully integrated industrial process control systems for bulk-process-handling applications are designed and built in Metso��’s in-house UL-listed panel shop. These systems are used in a wide variety of applications to streamline production operations. Production monitoring and management features are programmed for the user’s choice of automation platforms. Production and maintenance schedules can be configured on one server that logs and reports real-time and historical production data, downtime data, production trends, and maintenance. Reports can be detailed as required. Metso Minerals Industries Inc., Brunswick, OH 800-827-9237 www.metso.com

Click to enlarge

Remote Weight DisplayThe SB500 remote display provides maximum weight visibility up to 250 feet away. Typically used with vehicle scales, it features a red/green traffic light and four-way directional arrows for traffic coordination of trucks pulling on and off a scale for weighments. Cardinal offers custom programmable software to create your own characters or graphics. Cardinal Scale Mfg. Co., Webb City, MO 800-441-4237 www.cardinalscale.com

Sub-Sieve Sizer

Sub-Sieve Sizer

Particulate Systems, a brand of Micromeritics Instrument Corp., has been granted exclusive global distribution of the H.E.L. Limited Subsieve AutoSizer (SAS), a modernized and improved version of the Fisher Model 95 Sub-Sieve Sizer. The SAS has improved the established air-permeability particle sizing technique. The instrument combines the benefits of true unattended operation, ease of use, touch-screen control, and data capture using H.E.L.’s proprietary WinISO software platform. Air-permeability techniques generate average specific surface area data for powder samples. The specific surface area of particles has an impact on the physical properties of powders and has been the focus of much attention from pharmaceutical, paint, toner, and geological industries. Micromeritics Instrument Corp., Norcross, GA 770-662-3688 www.micromeritics.com

Click to enlarge

Self-Cleaning Acoustic SwitchThe Gladiator acoustic switch uses acoustic wave technology in a new sender/receiver form for blocked chute detection, point level detection, and anti-collision for heavy machinery. The Gladiator amplifier powers two AW transducers, which use Hawk-developed software in which both units pulse and receive each other’s acoustic echoes. When the path between the transducers is blocked, the units immediately detect the presence/absence change of the return signal and trigger a communications relay for indication or control purposes. The transducers work either together or independently to detect pulse interference, allowing twice the application security. The transducers are self cleaning and do not require contact with the product. Hawk Measurement, Middleton, MA 888-429-5538 www.hawkmeasure.com

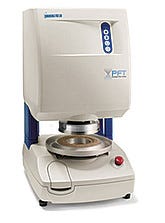

Powder Flow Tester

Powder Flow Tester

Developed in cooperation with the Wolfson Centre at the University Greenwich, UK, this instrument delivers quick/easy analysis of powder flow behavior. The PFT is ideal for manufacturers who need to eliminate the downtime and expense that occur when hoppers/silos fail to discharge. Customers can also perform QC checks on incoming materials, quickly characterize new formulations, and adjust composition to match the flow behavior of established products. The unit features a variety of test options including: flow function, time consolidation, wall friction, and bulk density. Time estimates for the duration of each test are automatically calculated before the start of the test in case adjustments are needed. Brookfield Engineering Laboratories Inc., Middleboro, MA 800-628-8139 www.brookfieldengineering.com

Click to enlarge

Vibrating Element Solids Level SensorThe Model VHS vibrating element solids level sensor uses piezoelectric technology to create its harmonic vibration in the absence of material. When material is present at its single element probe the vibration is dampened and the sensor relay output changes state to indicate material presence. The Model VHS is ideal for detecting lightweight materials, for bins with changing materials, and where re-calibration is to be eliminated. Its standard rod probe design works with process temperatures as high as 230°F, and the optional high-temperature design works with process material temperatures up to 320°F. BlueLevel Technologies, Rock Falls, IL 815-625-2224 www.blueleveltechnologies.com

Guided Wave Radar Level Sensor

Guided Wave Radar Level Sensor

The Flexar guided wave radar sensor is a real-time, continuous bin level measurement system using TDR (time domain reflectometry) principles where radar pulses are focused down to the material surface by the unit’s wave guide (a heavy-duty cable) where the time-of-flight of the pulse reflection back to the instrument electronics is directly related to the empty distance in the vessel and the material level. Guided wave radar technology has proven successful for most powder and bulk solids applications, including dusty conditions. It is also suitable for a multitude of liquid applications. The real-time measurement ability of the Flexar works well for dynamic storage situations including concrete batch plants, grain elevators during peaks times, and in balancing material levels in surge bins that supply pellets used to fuel furnace or boiler fires. Monitor Technologies LLC, Elburn, IL 800-766-6486 www.monitortech.com

You May Also Like