January 19, 2010

Single-Drive Feeder

The Tecweigh QC10 single-drive feeder couples a Flex-Feed polyurethane hopper with an opening in the bottom and the ability to agitate the hopper without driving the auger. When material needs to be changed, simply stop the feeder and place a reclaim container underneath. Then open the bottom discharge slide gate (or remove the plug) and run the drive motor in reverse. Tecnetics Industries Inc., St. Paul, MN 800-536-4880 www.tecweigh.com

The Tecweigh QC10 single-drive feeder couples a Flex-Feed polyurethane hopper with an opening in the bottom and the ability to agitate the hopper without driving the auger. When material needs to be changed, simply stop the feeder and place a reclaim container underneath. Then open the bottom discharge slide gate (or remove the plug) and run the drive motor in reverse. Tecnetics Industries Inc., St. Paul, MN 800-536-4880 www.tecweigh.com

Loss-in-Weight Feeder

The AccuFeed uses molded composite components and a modular design to reduce cost and delivery time. Available in capacities up to 600 cu ft/hr, the patented feeder employs controlled vibration to achieve volumetric accuracies of ±1–2%. The machine disassembles quickly for cleaning and meets FDA and USDA sanitary requirements. The company stocks popular sizes for immediate delivery. AccuFeeds may be scale mounted for batch or continuous weigh feeding applications. Vibra Screw Inc., Totowa, NJ 973-256-7410 www.vibrascrew.com

The AccuFeed uses molded composite components and a modular design to reduce cost and delivery time. Available in capacities up to 600 cu ft/hr, the patented feeder employs controlled vibration to achieve volumetric accuracies of ±1–2%. The machine disassembles quickly for cleaning and meets FDA and USDA sanitary requirements. The company stocks popular sizes for immediate delivery. AccuFeeds may be scale mounted for batch or continuous weigh feeding applications. Vibra Screw Inc., Totowa, NJ 973-256-7410 www.vibrascrew.com

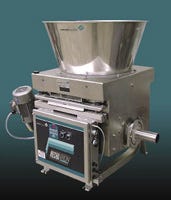

Pneumatic Feeders

This line of pneumatic feeders is designed to meet the needs of feeding applications up to 8 tn/hr. Engineered for the rugged plant environment, the feeders feature durable, easy-to-clean, all stainless-steel construction to ensure compliance with the tight sanitary regulations specified by the food, chemical, and pharmaceutical industries. Pneumatic drive systems eliminate the hazards of sparks or heat, and run efficiently and quietly (65 dBa). These feeders can be set to deliver a constant feed rate or an exact amount for batch processes. Magnetic Products Inc., Highland, MI 800-544-5930 www.mpimagnet.com

This line of pneumatic feeders is designed to meet the needs of feeding applications up to 8 tn/hr. Engineered for the rugged plant environment, the feeders feature durable, easy-to-clean, all stainless-steel construction to ensure compliance with the tight sanitary regulations specified by the food, chemical, and pharmaceutical industries. Pneumatic drive systems eliminate the hazards of sparks or heat, and run efficiently and quietly (65 dBa). These feeders can be set to deliver a constant feed rate or an exact amount for batch processes. Magnetic Products Inc., Highland, MI 800-544-5930 www.mpimagnet.com

High-Speed Feeders

This series of ac-operated high-speed feeders is designed for high-speed feeding of light, bulky materials. These rugged and powerful feeders are ideal for scales and other applications that require higher throughput and advanced control. In addition to advanced high-speed feed rates, these feeders feature a quick-stopping characteristic to ensure accurate handling of materials for economy and efficiency in mixing, weighing, batching, packaging, and bagging operations. Eight models are available. Eriez, Erie, PA 888-300-3743 www.eriez.com

This series of ac-operated high-speed feeders is designed for high-speed feeding of light, bulky materials. These rugged and powerful feeders are ideal for scales and other applications that require higher throughput and advanced control. In addition to advanced high-speed feed rates, these feeders feature a quick-stopping characteristic to ensure accurate handling of materials for economy and efficiency in mixing, weighing, batching, packaging, and bagging operations. Eight models are available. Eriez, Erie, PA 888-300-3743 www.eriez.com

Precise Feeder Systems

By combining the precision PosiPortion feeder with any of three types of conveyors or bulk bag unloading equipment, Hapman can tailor a system to handle product and measure up to specifications. Systems are available in a range of capacities and options to increase process efficiency and accuracy. All come with a performance guarantee. Hapman, Kalamazoo, MI 800-427-6260 www.ideasthatmove.com

By combining the precision PosiPortion feeder with any of three types of conveyors or bulk bag unloading equipment, Hapman can tailor a system to handle product and measure up to specifications. Systems are available in a range of capacities and options to increase process efficiency and accuracy. All come with a performance guarantee. Hapman, Kalamazoo, MI 800-427-6260 www.ideasthatmove.com

Redesigned Volumetric Feeder

The new design of the MetaTech feeder features only two moving parts (drive and screw) to ensure reliable performance with minimal process downtime and maintenance expense. The feeder also features a compact, space-saving design, low maintenance o-ring sealed inline direct drive, new Delrin bushing, and an agitator/conditioner screw to maintain consistent product density and completely fill the feed screw for highly accurate (±1–1.5%) feeding. Interchangeable screw/tube combinations are available in ½ to 6 in. sizes and permit feed rates from 0.05 to 550 cu ft/hr. The feeder is available in a wide range of models including space-saving mini, sanitary, and combination feeder/conveyor units. Metalfab Inc., Vernon, NJ 800-764-2999 www.metalfabinc.com

The new design of the MetaTech feeder features only two moving parts (drive and screw) to ensure reliable performance with minimal process downtime and maintenance expense. The feeder also features a compact, space-saving design, low maintenance o-ring sealed inline direct drive, new Delrin bushing, and an agitator/conditioner screw to maintain consistent product density and completely fill the feed screw for highly accurate (±1–1.5%) feeding. Interchangeable screw/tube combinations are available in ½ to 6 in. sizes and permit feed rates from 0.05 to 550 cu ft/hr. The feeder is available in a wide range of models including space-saving mini, sanitary, and combination feeder/conveyor units. Metalfab Inc., Vernon, NJ 800-764-2999 www.metalfabinc.com

Volumetric Feeder

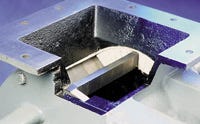

The Model 170-MI-5 volumetric feeder was designed to accurately meter a wide range of dry solid ingredients at feed rates as low as 0.0012 cu ft/hr. Designed with quick-disconnect features throughout, the entire feeder can be disassembled and reassembled in just minutes, without the need for any tools. The unit is designed for total product cleanout and is ideal for those applications where frequent product changeover is a requirement. Thorough cleaning has been made simple and quick, making the unit well-suited for both sanitary and pharmaceutical applications. Acrison Inc., Moonachie, NJ 201-440-8300 www.acrison.com

The Model 170-MI-5 volumetric feeder was designed to accurately meter a wide range of dry solid ingredients at feed rates as low as 0.0012 cu ft/hr. Designed with quick-disconnect features throughout, the entire feeder can be disassembled and reassembled in just minutes, without the need for any tools. The unit is designed for total product cleanout and is ideal for those applications where frequent product changeover is a requirement. Thorough cleaning has been made simple and quick, making the unit well-suited for both sanitary and pharmaceutical applications. Acrison Inc., Moonachie, NJ 201-440-8300 www.acrison.com

Screw Feeders

Mechatron feeders are designed to feed a wide variety of bulk solid materials such as magnesium oxide, cabosil, calcium chloride, TiO2, lactose, and carbon black for process applications. Feeders are provided volumetrically or gravimetrically in single- or twin-screw configurations with a wide range of customer-driven attributes including ac drive packages, flexible conical, or all stainless-steel hoppers, and helix designs capable of feed rates from 0.002 to 1100 cu ft/hr. All feeders can be disassembled, cleaned, reconfigured, and serviced from the non-process side of the feeder, eliminating the need to remove upper extension hoppers, bins, bulk bags or IBC’s for general maintenance of the feeder. Schenck AccuRate, Whitewater, WI 800-606-9248 www.accuratefeeders.com

Mechatron feeders are designed to feed a wide variety of bulk solid materials such as magnesium oxide, cabosil, calcium chloride, TiO2, lactose, and carbon black for process applications. Feeders are provided volumetrically or gravimetrically in single- or twin-screw configurations with a wide range of customer-driven attributes including ac drive packages, flexible conical, or all stainless-steel hoppers, and helix designs capable of feed rates from 0.002 to 1100 cu ft/hr. All feeders can be disassembled, cleaned, reconfigured, and serviced from the non-process side of the feeder, eliminating the need to remove upper extension hoppers, bins, bulk bags or IBC’s for general maintenance of the feeder. Schenck AccuRate, Whitewater, WI 800-606-9248 www.accuratefeeders.com

Volumetric Tube Feeder

The Series VTF volumetric tube feeder is available in a range of sizes from 3 to 9 in. in diameter and is capable of feed rates to 350 lb/min. A wide range of inlet to discharge centers allows for fitment into most processes. Features include a sleek round tube design with extended keel inlet that allows for smooth bridge free flow to feed zone. Oversized discharge eliminates discharge jams. A rear-mounted hollow shaft drive provides easy auger removal and cleaning. The discharge end includes a tool-free clamp and cover for fast access. The vacuum-tight design makes this feeder suitable for mounting directly to a vacuum receiver without the need for an airlock, supports, or flexible connections. HAF Equipment Inc., Centerville, MN 651-653-5098 www.hafequipment.com

The Series VTF volumetric tube feeder is available in a range of sizes from 3 to 9 in. in diameter and is capable of feed rates to 350 lb/min. A wide range of inlet to discharge centers allows for fitment into most processes. Features include a sleek round tube design with extended keel inlet that allows for smooth bridge free flow to feed zone. Oversized discharge eliminates discharge jams. A rear-mounted hollow shaft drive provides easy auger removal and cleaning. The discharge end includes a tool-free clamp and cover for fast access. The vacuum-tight design makes this feeder suitable for mounting directly to a vacuum receiver without the need for an airlock, supports, or flexible connections. HAF Equipment Inc., Centerville, MN 651-653-5098 www.hafequipment.com

Feeder/Screener

This dynamically balanced, natural frequency, or electro-mechanical vibratory screener feeder conveys product while classifying to specific particle distribution curves. Units can be volumetric flow rate feed design. Construction can be suited to chemical, food, dairy, and pharmaceutical industries. Machine and Process Design Inc., Anoka, MN 763-427-9991 www.mpd-inc.com

This dynamically balanced, natural frequency, or electro-mechanical vibratory screener feeder conveys product while classifying to specific particle distribution curves. Units can be volumetric flow rate feed design. Construction can be suited to chemical, food, dairy, and pharmaceutical industries. Machine and Process Design Inc., Anoka, MN 763-427-9991 www.mpd-inc.com

High-Precision Feeder

The Dyna-Slide high-precision air-activated feeder combines low-pressure compressed air and gravity to fluidize and convey most fine dry granular materials. The low-profile design is totally enclosed and dust-free, making it ideal for conveying from silos to weigh scales, hoppers to weigh scales, and feeding from multiple discharge points to mixers. The high-energy efficiency and ease of installation contribute to a cost-effective solution to conveying, even over long distances. With Dribble Feed Control, the unit will provide up to a 100:1 turndown ratio when feeding most fine (30 mesh to sub-micron) fludizable powders and granules. Dynamic Air Inc., St. Paul, MN 651-484-2900 www.dynamicair.com

The Dyna-Slide high-precision air-activated feeder combines low-pressure compressed air and gravity to fluidize and convey most fine dry granular materials. The low-profile design is totally enclosed and dust-free, making it ideal for conveying from silos to weigh scales, hoppers to weigh scales, and feeding from multiple discharge points to mixers. The high-energy efficiency and ease of installation contribute to a cost-effective solution to conveying, even over long distances. With Dribble Feed Control, the unit will provide up to a 100:1 turndown ratio when feeding most fine (30 mesh to sub-micron) fludizable powders and granules. Dynamic Air Inc., St. Paul, MN 651-484-2900 www.dynamicair.com

Recirculating Spreader-Feeder

This recirculating spreader-feeder evenly distributes powder and bulk coatings onto food products as they pass between the unit’s longitudinal discharge hopper and its lower collection hopper. The mobile unit is positioned so a wire conveyor belt with items to be coated passes above the unit’s lower collection hopper, as a uniform curtain of the coating material descends from the upper discharge hopper that has multiple ports to apportion material across its length. A small-diameter rotating agitator promotes uniform discharge through an adjustable screen that spans a gap along the hopper bottom. A centerless auger along the bottom of the longitudinal collection hopper feeds material into the intake adapter of a side-mounted flexible screw conveyor. This elevates the material into a horizontally oriented conveyor positioned above a longitudinal discharge hopper. Flexicon Corp., Bethlehem, PA 888-353-9426 www.flexicon.com

This recirculating spreader-feeder evenly distributes powder and bulk coatings onto food products as they pass between the unit’s longitudinal discharge hopper and its lower collection hopper. The mobile unit is positioned so a wire conveyor belt with items to be coated passes above the unit’s lower collection hopper, as a uniform curtain of the coating material descends from the upper discharge hopper that has multiple ports to apportion material across its length. A small-diameter rotating agitator promotes uniform discharge through an adjustable screen that spans a gap along the hopper bottom. A centerless auger along the bottom of the longitudinal collection hopper feeds material into the intake adapter of a side-mounted flexible screw conveyor. This elevates the material into a horizontally oriented conveyor positioned above a longitudinal discharge hopper. Flexicon Corp., Bethlehem, PA 888-353-9426 www.flexicon.com

Bulk Material Feeders

These bulk material feeders provide accurately measured introduction of material into processing and packaging operations. Regardless of material characteristics, the feeders deliver a consistent and repeatable feed of material, whether in continuous flow for pre-feed or feed applications, or in intermittent flow for batching applications. Integrated automation pushes controls functionality farther out and deeper into feeder operations to optimize total line throughput and deliver a standard, system-wide, data report from the control layer. Feeder control, communication, sensing, monitoring, and reporting are driven by a single, system-wide, touch screen HMI. National Bulk Equipment Inc., Holland, MI 616-399-2220 www.nbe-inc.com

These bulk material feeders provide accurately measured introduction of material into processing and packaging operations. Regardless of material characteristics, the feeders deliver a consistent and repeatable feed of material, whether in continuous flow for pre-feed or feed applications, or in intermittent flow for batching applications. Integrated automation pushes controls functionality farther out and deeper into feeder operations to optimize total line throughput and deliver a standard, system-wide, data report from the control layer. Feeder control, communication, sensing, monitoring, and reporting are driven by a single, system-wide, touch screen HMI. National Bulk Equipment Inc., Holland, MI 616-399-2220 www.nbe-inc.com

Abrasion-Resistant Ceramic Feeder

Lined with a thick ceramic coating that is designed to resist the most abrasive materials, this abrasion-resistant ceramic feeder offers heavy-duty design and construction. Features include: longer life; 0.100-in-thick ceramic bore; Tungsten carbide throat protection; heavy-duty fabricated eight-vane rotor; Tungsten carbide rotor vane and shroud tips, 0.100-in. thick; air purge seal connections; air gap between seals and bearings; outboard sealed ball bearings; and a maximum operating temperature of 350°F. Abrasive applications include fly ash, gold ore, rutile ore, sand, feldspar, alumina, kaolin clay, raw limestone, lignite, cement, diatomaceous earth, and copper concentrate. FLSmidth Inc., Bethlehem, PA 800-523-9482 www.flsmidth.com

Lined with a thick ceramic coating that is designed to resist the most abrasive materials, this abrasion-resistant ceramic feeder offers heavy-duty design and construction. Features include: longer life; 0.100-in-thick ceramic bore; Tungsten carbide throat protection; heavy-duty fabricated eight-vane rotor; Tungsten carbide rotor vane and shroud tips, 0.100-in. thick; air purge seal connections; air gap between seals and bearings; outboard sealed ball bearings; and a maximum operating temperature of 350°F. Abrasive applications include fly ash, gold ore, rutile ore, sand, feldspar, alumina, kaolin clay, raw limestone, lignite, cement, diatomaceous earth, and copper concentrate. FLSmidth Inc., Bethlehem, PA 800-523-9482 www.flsmidth.com

Vibratory Net-Weigh Feeders

TE-10 series net-weigh feeders use a variable-speed electronic scale designed for weighments of 2 oz to 25 lb. It is capable of both powder and granule applications, and of filling up to 18 bags per minute. Features include tool-less disassembly for easy cleanup and dual set points. Taylor Products, a division of Magnum Systems, Parsons, KS 888-882-9567 www.magnumsystems.com

TE-10 series net-weigh feeders use a variable-speed electronic scale designed for weighments of 2 oz to 25 lb. It is capable of both powder and granule applications, and of filling up to 18 bags per minute. Features include tool-less disassembly for easy cleanup and dual set points. Taylor Products, a division of Magnum Systems, Parsons, KS 888-882-9567 www.magnumsystems.com

Quick Change Screw Feeder

The T35/S60 single/twin screw quick change feeder is designed for applications requiring fast cleaning and the maximum possible material handling and changeover flexibility. It is available in volumetric or loss-in-weight configurations. The single-screw feeding elements handle free-flowing powders, granules, pellets, and other non-flooding materials. The twin-screw elements control floodable powders and more difficult sticky or hard-to-flow materials. Typical applications include: where frequent and easy cleaning is required; where product contamination is not allowed; where only one feeder must handle a large variety of products; and where ingredients must be changed quickly and cleanly. K-Tron Process Group/K-Tron Feeders, Pitman, NJ 856-256-3265 www.ktron.com/QC

The T35/S60 single/twin screw quick change feeder is designed for applications requiring fast cleaning and the maximum possible material handling and changeover flexibility. It is available in volumetric or loss-in-weight configurations. The single-screw feeding elements handle free-flowing powders, granules, pellets, and other non-flooding materials. The twin-screw elements control floodable powders and more difficult sticky or hard-to-flow materials. Typical applications include: where frequent and easy cleaning is required; where product contamination is not allowed; where only one feeder must handle a large variety of products; and where ingredients must be changed quickly and cleanly. K-Tron Process Group/K-Tron Feeders, Pitman, NJ 856-256-3265 www.ktron.com/QC

Vibratory Feeders

BEST vibratory feeders are designed to smoothly convey products. Flow of material is adjustable and the flow rate can be variable or fixed. Available in electric- or air-operated models, these heavy-duty vibratory feeders can be designed with above-, below-, or side-mounted drives and can be arranged for base mounting or overhead suspension. The feeders come in custom vibrating trough lengths and special trough designs are available. The feeders are available in several basic models including air-operated light duty, air-operated heavy duty, twin-motor vibrating pan and grizzly feeders, electromagnetic, twin motor, and special application feeders. Metso Minerals Industries Inc., Brunswick, OH 800-827-9237 www.bestvibes.com

BEST vibratory feeders are designed to smoothly convey products. Flow of material is adjustable and the flow rate can be variable or fixed. Available in electric- or air-operated models, these heavy-duty vibratory feeders can be designed with above-, below-, or side-mounted drives and can be arranged for base mounting or overhead suspension. The feeders come in custom vibrating trough lengths and special trough designs are available. The feeders are available in several basic models including air-operated light duty, air-operated heavy duty, twin-motor vibrating pan and grizzly feeders, electromagnetic, twin motor, and special application feeders. Metso Minerals Industries Inc., Brunswick, OH 800-827-9237 www.bestvibes.com

Quick Clean Feeder

The ACS quick clean feeder can be disassembled and reassembled in less than two minutes. It is used for pneumatic conveying and bulk material handling applications and is available in light-, medium-, and heavy-duty models with square or round flanges. The feeder is available in the CI, MD, DR-S, AF feeder, and S-pellet feeder valves. The valve handles pressure differentials up to 15 psi and can be constructed of cast iron or stainless steel. Valves are available in sizes from 4 to 16 in., feature a rugged heavy-duty housing, and have precision-machined internal surfaces that form an effective seal. ACS Valves, Caledonia, ON, Canada 905-765-2004 www.acsvalves.com

The ACS quick clean feeder can be disassembled and reassembled in less than two minutes. It is used for pneumatic conveying and bulk material handling applications and is available in light-, medium-, and heavy-duty models with square or round flanges. The feeder is available in the CI, MD, DR-S, AF feeder, and S-pellet feeder valves. The valve handles pressure differentials up to 15 psi and can be constructed of cast iron or stainless steel. Valves are available in sizes from 4 to 16 in., feature a rugged heavy-duty housing, and have precision-machined internal surfaces that form an effective seal. ACS Valves, Caledonia, ON, Canada 905-765-2004 www.acsvalves.com

Precision Rotary Feeders

Available in various sizes, these feeders have an exra-thick barrel that is designed to be rebuilt many times before needing replacement. Optional feeder mounting frames are available with an injector tee, check valve, and bottom knife access door custom designed to fit the line size and center lines. Special materials such as stainless steel or abrasion resistant Tribraze steel are also available. Feeders can be designed to exact size specifications. A trade-in allowance is available for used feeders. Precision Machine & Manufacturing Inc., Eugene, OR 800-722-9841 www.premach.com

Available in various sizes, these feeders have an exra-thick barrel that is designed to be rebuilt many times before needing replacement. Optional feeder mounting frames are available with an injector tee, check valve, and bottom knife access door custom designed to fit the line size and center lines. Special materials such as stainless steel or abrasion resistant Tribraze steel are also available. Feeders can be designed to exact size specifications. A trade-in allowance is available for used feeders. Precision Machine & Manufacturing Inc., Eugene, OR 800-722-9841 www.premach.com

You May Also Like