May 6, 2010

Explosion Isolation Pinch Valve

Explosion Isolation Pinch Valve

Booth 3635 - This pneumatically-operated Explosion Isolation Pinch Valve (EIPV) further expands the company’s full range of explosion protection solutions. The EIPV is an economical form of Explosion Isolation—a method for preventing deflagration propagation through interconnecting pipes or conveying lines, thereby protecting additional process equipment and operating locations. The EIPV consists of a heavy-duty cast valve body containing a rugged elastomeric sleeve. Upon explosion detection, compressed air is released at high speed and within milliseconds the sleeve is pinched to full closure, stopping explosion propagation beyond the valve. Fike, Blue Springs, MO 800-937-3453 www.fike.com

Spark Detection and Extinguishing Systems

Spark Detection and Extinguishing Systems

Booth 2910 - As a preventative method against fire and dust explosions, these spark detection and extinguishing systems are used in production equipment, material handling, dust collection, and pneumatic conveying systems. When working materials, sparks are created very quickly. A dull tool, a damaged fan bearing, an overheated motor, or a foreign object within the material can be the cause. This is a constant danger for all facilities where combustible materials are being worked, exhausted, transported, filtered, or dried. The sensors detect even the smallest spark’s infrared radiation. They signal the control console to initiate instantaneous countermeasures, thus preventing the spark from entering the dust collector or other downstream areas. The system extinguishes sparks without stopping production. GreCon Inc., Tigard, OR 503-641-7731 www.grecon-us.com

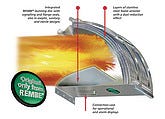

Flameless Indoor Explosion Venting

Flameless Indoor Explosion Venting

Booth 1460 - The Q-Rohr-3 guarantees indoor explosion venting without any flame and dust propagation. It is recognized worldwide by NFPA68 and accepted by VDI-3673 and prEN 14797. The unit is maintenance-free, saving costs related to active suppression systems. It consists of an integrated bursting disc that vents the explosion wave in a controlled manner into the unit. Flame gases with temperatures higher than 2732°F are cooled down to less than 195°F via energy transfer within the special stainless-steel mesh filter inlet. This leads to a reduction of the expanding gas volume as it extinguishes the flame. Additionally, the pressure rise and high noise level associated with a free-vented explosion are reduced to negligible levels. The stainless-steel mesh filter guarantees that no burned or unburned dust passes off the unit, which is reusable immediately after cleaning. REMBE GmbH, Brilon, Germany +49 2961 74050 www.q-rohr.com

Fine Water Protection System

Fine Water Protection System

Booth 3007 - The Minifog fine water protection system is Factory Mutual-approved for the protection of industrial continuous presses. It is an effective fire fighting system that protects personnel and facility investments. It uses small amounts of water at low pressure to minimize water damage and decreases downtime. The company will tailor a fire protection system to specific needs. Flamex Inc., Greensboro, NC 336-299-2933 www.sparkdetection.com

Explosion Isolation Flap

Explosion Isolation Flap

The explosion isolation flap is a fast-acting mechanical barrier designed to isolate the hazardous effects of an explosion in a dust collector or other equipment. It also ensures that no flames or explosion pressure are spread back through ducts to endanger employees and other vital equipment. It is robustly constructed and certified as a protective system in accordance with ATEX Directive 94/9/EC. Dantherm Filtration, 800-533-5286 www.danthermfiltration.us

Vent Integrity Sensor

Vent Integrity Sensor

Booth 2725 - The Type VIS vent integrity sensor continuously monitors explosion vents designed for protection of combustible dust process equipment. Owners and operators of material handling systems such as dust collectors, cyclones, and silos depend upon explosion vents for the safety of their investment in plant and personnel. This sensor provides a signal when any one of the burst control members present in all BS&B explosion vent types is compromised as a result of operational conditions, as well as annunciating vent activation. The sensor allows the plant owner/operator to take immediate action when normal operating conditions threaten the performance of this important safety device. It includes an electrically isolated supervisory circuit beneath the explosion vent gasket. A circuit passes over each of the controlled points of weakness that determine the vent relief pressure. BS&B Pressure Safety Management LLC, Tulsa, OK 918-664-3921 www.bsbsystems.com

Passive Explosion Isolation Valve

Passive Explosion Isolation Valve

Booth 3527 - The ProFlapPlus explosion isolation valve is a passive device that self-actuates by the pressure wave from an explosion inside a vented vessel, preventing the flame propagation to upstream processes. No triggering sensors or controllers are necessary to actuate the valve. When accompanied by an explosion relief vent, the valve provides a total passive protection solution while helping meet requirements of OSHA Combustible Dust Directive and NFPA 654. The unit is available in a wide range of sizes and is ATEX-certified for organic and inorganic dusts with a KST value up to 300 bar m/s. With its integrated sensors, valve operating conditions are continuously monitored, allowing for extended maintenance intervals. Fenwal Protection Systems, Ashland, MA 508-881-2000 www.fenwalprotection.com

Explosion Vent

Explosion Vent

Booth 2442 - In the event of a deflagration, the GLV-F explosion vent opens up to release pressure and minimize damage. The vent features a built-in outlet frame and gasket for easy installation, eliminating the need to fabricate an angle iron hold down frame. The GLV-F meets NFPA 61 standards for the prevention of explosions in agricultural and food processing facilities. The company also offers precision-manufactured rupture discs and other pressure relief products. Oseco, Broken Arrow, OK 800-395-3475 www.oseco.com

Desktop Safety System Software

Desktop Safety System Software

Booth 2531 - The Desktop Safety System (DSSTM) is user-friendly decision support software that quickly and easily assists in the assessment and control of dust explosion and electrostatic hazards. The DSSTM can be used to identify fire and explosion hazards during powder and bulk solid handling and processing operations and to suggest appropriate precautions and controls. Based on a proprietary algorithm developed by Chilworth Global from more than two decades of process safety consulting and testing experience, the DSSTM has been validated for a wide variety of powder and bulk solid handling operations and equipment. Features include: Web-based design; create a combustible dust test database; interpret combustible dust test data; recommends tests needed for specific operations; and a library of common industrial operations. Chilworth Technology Inc., Plainsboro, NJ 609-799-4449 www.chilworth.com

You May Also Like