January 4, 2012

SpaceSaver Dust Collectors

SpaceSaver Dust Collectors

Based on customer requests, the SpaceSaver dust collector is up to 75% smaller than traditional baghouse collectors and features leak-free, durable cartridges. A superior cleaning mechanism with directed airflow makes SpaceSaver a tough, small, efficient dust collector. The unit’s low-profile, compact design addresses a need where high efficiency collection is required, yet a small footprint is necessary. SpaceSaver is easy to access and offers tool-free maintenance. It uses one-piece cartridges, instead of a bag and cage combination, making them easier to maintain. The cartridges are durable, easily washable, and leak-free. Made with nanofiber technology, they also trap dust more effectively. Applications include bucket elevator aspiration, belt conveyor transfer points, mixer ventilation, scale hopper ventilation, super sack fillers and unloaders, silo venting, hammer mill aspiration, and seed cleaning. Mac Process Inc., 888-831-5301 Kansas City, MO www.macprocessinc.com

Bin Discharger

Bin Discharger

A line of dependable and economical bin dischargers is available to system suppliers and OEMs. Based on more than 50 years of bin discharge experience, these units are ruggedly built, simple to install, and come with an unconditional performance guarantee. The discharger’s simple, compact design incorporates a range of features that include a leak-proof molded sleeve, heavy-duty suspension system, and long life vibrator. Vibra Screw Inc., Totowa, NJ 973-256-7410 www.vibrascrew.com

Conveyor Belt Tracking System

Conveyor Belt Tracking System

ASGCO offers an addition to its line of Tru-Trainer conveyor belt tracking idlers. The Tru-Trainer idlers react as the conveyor belt moves off center, maintaining the belt’s original position, minimizing belt wear and conveyor downtime. The dual return Tru-Trainer conveyor belt tracker is now available in a V-Return style, developed to accommodate the v-return conveyor systems that see excessive forces encountered when utilizing high tension, overland style conveyor systems, which often operate with wide conveyor belts to accommodate heavy loads. The V-Return Tru-Trainer is ideal for v-return overland conveyor systems. An external central pivot mechanism was designed, obviating the need for a single, large drum, and enabling a concentric and balanced rotation to be achieved. This results in extended bearing life and a fast and effective conveyor belt tracking system. ASGCO Manufacturing Inc., Allentown, PA 800-344-4000 www.asgco.com

Angled Frame Conveyors

Angled Frame Conveyors

AS40Z angled frame conveyors enable elevation changes that are not possible with a flat conveyor. The conveyors feature the same 1.95-in.-high rigid aluminum frame offered in other automation series conveyors. The design resists twisting, which is a leading cause of belt tracking issues in other conveyors. They also feature the Z-Track design to help make tracking simple. Optional V-Guide belts can assist in tracking, especially in hard-to-reach applications. AS40Z conveyors include tension release tails that flip up at the push of a button to allow easy under-belt cleaning. They then click back into place with all tracking adjustments retained. The reduced torque requirements allow the use of smaller motors than other angled frame conveyors, letting them fit into spaces other conveyors cannot. One such motor is the brushless DC motor that affords high-tech control in a small package. QC Industries LLC, Cincinnati, OH 513-753-6000 www.qcindustries.com

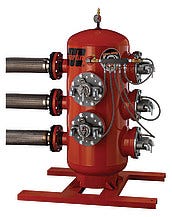

Air Cannon System

Air Cannon System

The Big Blaster Category 5 Hurricane air cannon system is a multi-valve air cannon solution that provides up to five application points utilizing a single 60-gal reservoir. The air cannon system helps protect components and workers from hazardous environments and improves flow efficiency, delivering flexibility and durability. Efficient material flow is maintained with a design that operates proficiently at five application points from a single air source, requiring fewer parts and less maintenance. The five independent valves are housed within a single tank. If one valve requires service, the multiple-valve air cannon system continues to function in nearly all cases, improving reliability. The centralized location of working components away from the point of application allows for shelter from exposure to high temperature environments and process dust. A single remotely located reservoir tank also eliminates the need to hang numerous heavy individual tanks on vessel walls. Martin Engineering USA, Neponset, IL 800-544-2947 www.martin-eng.com

You May Also Like