Industrial Feeders

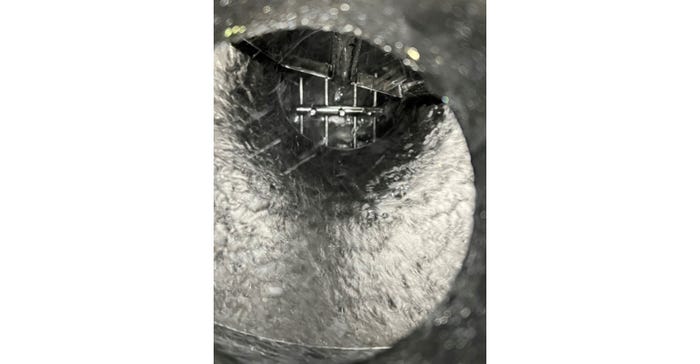

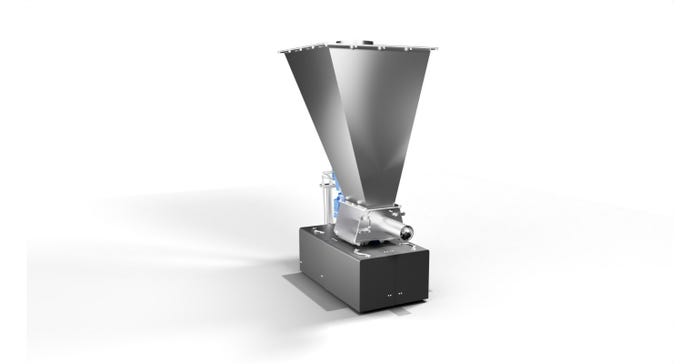

gravimetric feeder

Industrial Feeders

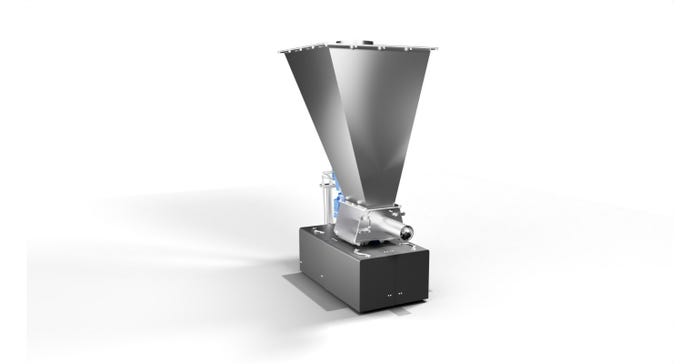

Thayer Scale Introduces New Gravimetric FeederThayer Scale Introduces New Gravimetric Feeder

Compact, easy-to-clean feeder provides responsive feed-rate control and accuracy.

Sign up for the Powder & Bulk Solids Weekly newsletter.