February 25, 2010

Heavy-Duty Bin Activators for Large Silos

Heavy-Duty Bin Activators for Large Silos

Exclusive ASME dished-head bin activators are designed for severe-duty service on large silos. The dished-head/lower-cone construction provides a compound slope profile that safely handles large head loads while preventing compaction at the outlet, a problem with single slope dischargers. Available in diameters up to 18 ft, the bin activators are equipped with Vibra Screw’s patented oil lubricated gyrator for extended service life.

Vibra Screw Inc., Totowa, NJ 973-256-7410 www.vibrascrew.com

Flow Discharge Aid

Flow Discharge Aid

The Mucon Promo-Flow discharge aid is an easy-to-install solution to existing discharge problems. The custom-made internally mounted screens are designed to transmit vibration directly into the product, preventing material bridging, rat holing, and segregation during discharge. The robust vibrators are mounted externally, activating the vibrating screens mounted on the inside of the silo wall at the points where the flow problem occurs. Rubber isolation mounts attach the system to the silo, preventing leakage through the mounting holes. The entire unit is allowed to vibrate the product while contributing no vibration to the silo itself.

Kemutec, Bristol, PA 215-788-8013 www.kemutecusa.com

Circular Bin Discharger

Circular Bin Discharger

The FloMaster circular bin discharger is a compact and totally enclosed positive discharge aid for hoppers and silos where the material to be handled has characteristics that make it difficult to discharge or control. A rotating arch breaker arm travels around the hopper bottom section of the silo, breaking any bridge of material that may have formed. This ensures a flow of material to the discharger is supplied to the single-, twin-, or three-stage units suiting the characteristics of the material to be handled and the throughputs required. Fabricated in mild steel, the FloMaster is designed to handle a wide variety of materials ranging from cocoa to wood flour. Capacities of up to 200 tn/hr are achievable with the two standard bin sizes of 32 and 40 in. in diameter.

Schenck Process, Whitewater, WI 800-558-0184 www.accuratefeeders.com

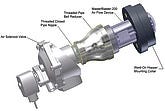

Pneumatic Flow Device

Pneumatic Flow Device

The Masterblaster pneumatic flow device gets stubborn powders and granular material in hoppers and silos to flow on demand. The unit sweeps the hopper inside wall with a pulse of high-pressure air that can reach out approximately 8 ft in diam, depending on model size and pressures. It can be constructed from a variety of materials, including stainless steel, high alloy carbon steel, duplex stainless steel, Inconel, and Hastelloy. It can also work with a variety of compressed gases, including carbon dioxide, nitrogen, or standard compressed air, depending on the applications and needs. The unit is available in three different sizes.

Integral Mechanical Systems LLC, Burbank, IL 708-357-3068 www.imsmasterblaster.com

Mechanical Silo Unloader

Mechanical Silo Unloader

This arch breaker features a vertical spindle fitted with flexible blades to ensure the mechanical discharge of dry solid materials from silos, rigid bins, or hoppers, while preventing the bulk material from jamming, bridging, compacting, or ratholing caused by vibration or fluidization. The mechanical unit not only gently and efficiently discharges bulk products, but integrates 1, 2, 3, or 4 precise volumetric screw feeders. Each screw feeder is totally independent and can feed up to 15,000 lb/hr with different length and throughput variations.

Sodimate Inc., Chicago, IL 773-665-8800 www.sodimate-inc.com

Dual Baffle Bin Activators

Dual Baffle Bin Activators

This rugged line of bin activators is designed and engineered to deliver high performance, high product quality, long-term reliability, and low maintenance over life of ownership. Available in a wide range of sizes from 2–16 ft in diam, each bin activator incorporates a dual baffle design that delivers continuous flow of dry materials without plugging, jamming, or bridging; an endless beaded flexible sleeve 7⁄16-in. thick with 3-ply reinforcement that will not puncture, slip, or leak; solid steel suspension arms bolted 90° that can each support up to 500,000 lb to ensure the bin activator remains attached to the bin and cannot move off center; and a unitized vibrator and motor in a single, sealed enclosure with no belts to slip or break—unconditionally guaranteed for 30 months. Each unit also comes with a performance guarantee. Metalfab Inc., Vernon, NJ 800-764-2999

Metalfab Inc., Vernon, 800-764-2999 NJ www.metalfabinc.com

Bin Aerator

Bin Aerator

The Model K Vibra-Jet bin aerator can be installed on any storage silo, bin, or hopper as a versatile and effective means of getting dry bulk materials, like carbon black or fine cement, to gravity feed more reliably at a low cost. Materials that tend to pack, bridge, or hang up can be made to flow freely and instantly upon demand. A triple seal has been designed into the unit to prevent back feeding to provide added reliability and extend the life of the unit. Dynamic Air Inc., St. Paul, MN 651-484-2900

Dynamic Air Inc., St. Paul, 651-484-2900 MN www.dynamicair.com

Bin Activating Discharger

Bin Activating Discharger

The Kraus GYRO EX bin activating discharger produces a controlled gyratory motion to positively withdraw granular materials from bins, storage silos, and hoppers at any desired rate for a consistent and reliable discharge. The unit uses a radial force to create a uniform circular motion on both the upper activation cone and the lower discharge cone. The stored material load is completely supported by the upper bin activation cone, which has a discharge angle less than the discharge cone. This means all materials feed faster from the lower discharge cone than from the upper bin activation cone, thus preventing the head load from compacting material in the lower cone for more reliable discharge without fear of ratholing. It can also be used as a loss-in-weight or gain-in-weight feeder and, in most applications, achieve turn down ratios of greater than 100 to 1.

Kraus Vibratory Equipment, St. Paul, MN 651-486-3069 www.krausvibratory.com

Flat-Bottom Bin Discharger

Flat-Bottom Bin Discharger

The Model 170-BD-30 bin discharger utilizes mechanically induced internal agitation to promote the discharge of dry solid ingredients from within a bin or hopper, typically for filling a feeder or to refill a weight-loss weigh feeder. The discharger is a self-emptying design with complete and total cleanout capability. It consists of a circular, nonconverging flat-bottom housing containing a horizontally mounted agitator (driven from beneath) for effectively discharging dry solid materials from within the storage bin or hopper to which it is attached. Product flows out of the storage bin and into the mating wide throat opening where the sweeping action of the slowly rotating agitator, across the discharger’s flat bottom, produces positive product discharge without compaction, attrition, or segregation.

Acrison Inc., Moonachie, NJ 201-440-8300 www.acrison.com

Vibrating Bin Discharger

Vibrating Bin Discharger

This vibrating bin discharger features a three-outlet discharge for promoting the flow of bulk material from storage into three separate downstream systems. The multioutlet discharger eliminates a downstream static diverter valve, freeing up headroom to allow more storage capacity and reducing overall system cost. The TENV (or TEXP) vibratory motor, with a 30-month warranty, provides a vibratory action that virtually eliminates ratholing and bridging. This action is isolated from the surrounding equipment via rubber-bushed cast ductile iron hanger arms and EPDM flexible connectors with stainless-steel clamps. The discharger inlet can be suspended above via a welded or bolted adapter ring, and each outlet can be provided with stub outlets, hammer-thru type maintenance gates, or knife gates with either hand wheel or air-operators.

Carman Industries Inc., Jeffersonville, IN 800-456-7560 www.carmanindustries.com

You May Also Like