November 11, 2010

Automatic Bagging Machines

Automatic Bagging Machines

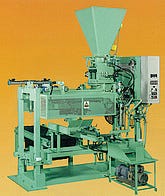

The 3CM-5 series automatic bagging machines are specifically designed for tight spaces. The baggers place an empty bag on the spout, fill it (typically 20-50 lb), and close the bag top (heat seal or sewing), all within the confines of the bagger. This system maintains bag-top control through this process in order to achieve a high degree of consistency and deliver maximum throughput. This series includes the 3CM-52, 3CM-55, and 3CM-5U machine models. American-Newlong Inc., Indianapolis, IN 317-787-9421 www.american-newlong.com

Click to enlarge

Sanitary Portable Bulk Bag DischargerThis portable system features electro-polished tubular 304 stainless steel construction with no tube penetrations and continuous TIG welds. Product contact surfaces are 316L stainless steel. A Sure-Seal pneumatic spout clamp system ensures dust-tight operation, while an exclusive 304 stainless steel Flo-Master pipe frame bag massaging system promotes discharge of non-free flowing materials. A 304 stainless steel Seal Master bag spout access chamber provides ergonomic discharge spout access. Material Transfer & Storage, Allegan, MI 800-836-7068 www.materialtransfer.com

Heat Sealer

Heat Sealer

As an entry level machine, the B-550 is available in a full range of styles and options that allow the user to configure it to meet specific requirements. It is available in both vertical and horizontal formats and in two feed directions. The technology features several standard options including emboss or ink coders, integrated conveyors, bagtop trimmers, bag counters, and stainless steel construction. The unit’s fast heat sealing makes it ideal for a wide range of applications. The use of fiberglass sealing bands provides superior seals and reduces machine wear. When bands are worn, they can be changed in minutes without tools by simply moving a lever. Bosch Packaging Technology Inc., New Richmond, WI 715-243-2503 www.boschpackaging.com

Click to enlarge

Air Packer SystemModel A valve bag packers are pneumatic aeration packers designed specifically for powders and powder mixes, such as flour, cement, and chemicals, although they also effectively handle granular materials. Capacity is 15 to 125 lb and up to 8 BPM. These pneumatic packers incorporate the company’s precise bulk and dribble fill cycles. Taylor Products, Parsons, KS 888-882-9567 www.taylorproducts.com

Hang-Weigh Filler

Hang-Weigh Filler

The hang-weighing option on this mobile bulk bag filler eliminates the need for recalibration after moving the unit to another location. In addition, the top-mounted load cell design removes the risk of potential damage to the sensitive weight sensors when moving the system throughout the plant. These fillers produce stable, easy-to-handle FIBCs that reduce warehousing and transportation costs. Hapman, Kalamazoo, MI 800-427-6260 www.hapman.com

Electronic Air Pressure Valve Packer

Electronic Air Pressure Valve Packer

The Model A1000 electronic air pressure packer utilizes a load cell and a user-friendly Model IDS440HS digital weigh indicator/controller for bagging fine, medium, and course dry materials. This model offers production rates of 4 to 8+ bags/min with weight accuracy of +/- 3 to 5 oz), at proper fluidization and uniform control of head pressure. It features heavy-duty construction with simple operation; has a full bottom chamber cover for easy clean out; dual filling speeds (bulk & dribble); a dust collection connection; and is coupled with a super quiet low pressure blower. Vic Systems International Inc., Shawnee Mission, KS 800-255-0445 www.vicsystemsintl.com

Bulk Bag Filler

Bulk Bag Filler

The Model BFB basic bulk bag filler performs low-capacity filling operations at minimal cost, and can be upgraded with performance enhancements including a material delivery system integrated with the user’s process equipment or bulk storage vessels. It is a lighter-duty version of the company’s heavy-gauge Twin-Centerpost filler, a patented design with two on-center posts that offer the structural integrity of four-post fillers but at lower material and fabrication costs and with less weight. It also affords easier access to the bag spout and loops according to the company. The filler is equipped as standard with fill head height adjustment via fork truck to accommodate all popular bag sizes, an inflatable cuff to seal the bag inlet spout, and a feed chute vent port for dust-free air displacement during filling. Performance can be enhanced by adding an inflator to expand the bag prior to filling, and a programmable scale system with flow control valve for automated filling by weight. Flexicon Corp., Bethlehem, PA 888-353-9426 www.flexicon.com

Compact Open-Mouth Gross-Weigh Gravity Filler

Compact Open-Mouth Gross-Weigh Gravity Filler

The 4300 compact open-mouth gross-weigh gravity filler is a compact filler that provides fast, accurate filling of open-mouth bags with free-flowing granular products such as seeds, grains, dry sand, rock salt, and plastic pellets. Design features include: pneumatic flow control gate, pneumatic bag clamps, electronic load cell weighing, bulk and dribble feed, display in lb and kg, auto tare, bag hold switch, auto hold for underweight bags, calibration routine, bag-in-place switch, bag clamp auto start switch, and dust pickup port. Filling rates of 10-14 bags/min with accuracies of +/- 2/10 of a pound can be achieved depending upon product characteristics with bag weight ranges of 20 to 110 lb. Chantland-MHS, Humboldt, IA 515-332-4045 www.chantland.com

Bulk Bag Unloaders

Bulk Bag Unloaders

BulkBuster bulk bag unloaders empty large bulk bags and get material where you want it in your process. Every precaution has been taken to ensure a safe and dust-free operation. A heavy-duty framework provides stability and operator safety. Operator efficiency is also maximized due to the simplicity of the designs and ease of operation when lifting, positioning, and emptying every bulk bag. Many styles and designs of bulk bag unloaders are engineered for specific materials. Dynamic Air Inc., St. Paul, MN 651-484-2900 www.dynamicair.com

Click to enlarge

Bulk Bag UnloadersBEST bulk bag unloaders provide dust-free product discharge from bulk bags. Expandable and flexible, they are available in three models: Model BDS bag-dump station with air-vibrator-shaker grate; Model MTU with 2500-4000-lb capacity; and heavy-duty Model BBU with vibratory-motor agitation. Many options are available. These unloaders can be loaded with fork trucks, cranes, or by hand. All standard unloaders incorporate a neoprene facial seal with 17-in.-diam discharge outlet for dust-tight operation. Metso Minerals Industries Inc., Brunswick, OH 800-827-9237 www.bestvibes.com

Bulk Liners

Gennex bulk liners are used for packaging products in the food, chemical, and pharmaceutical industries. They are form-fit and custom engineered to provide the specific barrier properties needed for the product being packaged including protection from oxygen and moisture. Foil liners are not completely flexible and are prone to cracking when used inside of a flexible package that may pull and twist during handling and shipment. Once the liner is cracked, the barrier no longer exists and the product inside is compromised. These liners utilize a co-extruded, multi-layer film that withstands real-world handling insuring that the barrier remains intact. They cost less than comparable foil liners and can be recycled. Plasport Inc., Traverse City, MI 888-584-4422 www.plascongroup.com

Click to enlarge

Low-Level PalletizerThe 72AE palletizer combines the economy and accessibility of a floor-level palletizer with the speeds typically associated with high-level machines. This design incorporates an extended accumulation table that allows continuous layer forming during layer transfer and stacking, thereby achieving increased volume of up to 35 units per minute. Energy-efficient electric motors provide whisper-quiet operation, and all layer patterns and pallet configurations are programmed for easy startup and control. The Model 72AE can palletize cases, trays, bags, or totes. Changeover is automatic: simply choose the product configuration at the operator touchscreen panel. A-B-C Packaging Machine Corp., Tarpon Springs, FL 727-937-5144 www.abcpackaging.com

You May Also Like