March 8, 2010

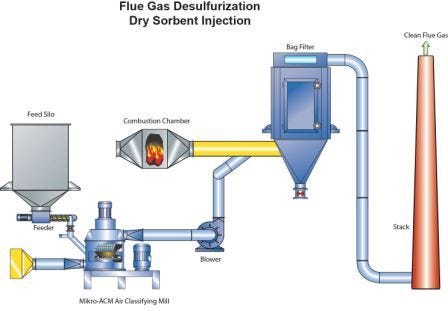

With tightening standards for coal-fired and biomass power plants to reduce greenhouse and acid-rain gas emissions, Hosokawa is designing and manufacturing milling systems to produce grades of fine-ground sodium bicarbonate (SBC) and/or trona (sodium sesquicarbonate), to remove sulfur oxides (SOx) - a by-product of combustion of sulfur containing fossil fuels. When particles are reduced in size, the total surface area of the finer particles increases, allowing for greater reactivity. After years of collaboration with customers, Hosokawa has standardized on system sizes and packages, from as little as 100 to 50,000 lb/hr of ground SBC or trona to average particle sizes as small as 5 µm, thereby improving SOx removal efficiencies. Hosokawa’s ACM system for dry sorbent injection, takes the feedstock from storage silos and grinds and classifies it to the desired particle size before conveying the powder via a material handling fan to the flue gas stack where it reacts with SO2, reacting with and removing the gas as a harmless solid which is then trapped in a filter-house or electrostatic dust precipitator.

With tightening standards for coal-fired and biomass power plants to reduce greenhouse and acid-rain gas emissions, Hosokawa is designing and manufacturing milling systems to produce grades of fine-ground sodium bicarbonate (SBC) and/or trona (sodium sesquicarbonate), to remove sulfur oxides (SOx) - a by-product of combustion of sulfur containing fossil fuels. When particles are reduced in size, the total surface area of the finer particles increases, allowing for greater reactivity. After years of collaboration with customers, Hosokawa has standardized on system sizes and packages, from as little as 100 to 50,000 lb/hr of ground SBC or trona to average particle sizes as small as 5 µm, thereby improving SOx removal efficiencies. Hosokawa’s ACM system for dry sorbent injection, takes the feedstock from storage silos and grinds and classifies it to the desired particle size before conveying the powder via a material handling fan to the flue gas stack where it reacts with SO2, reacting with and removing the gas as a harmless solid which is then trapped in a filter-house or electrostatic dust precipitator.

Hosokawa Micron Powder Systems, Summit, NJ 908-277-205 www.hmicronpowder.com

You May Also Like