May 11, 2007

Porous Granular Material Agglomeration

Porous Granular Material Agglomeration

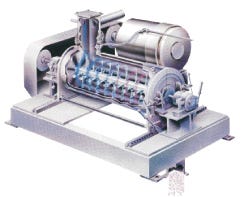

Achieving optimum particle size, shape, and density economically and consistently are key features of the Turbulizer. Designed for continuous agglomeration, mixing, and coating, the unit features helical paddles with adjustable angle and clearance. The design provides maximum flexibility to control residence times and shear angle. Horizontal orientation creates larger particles with higher density. Granules as large as 3 mm are possible. High tip speed promotes excellent heat transfer. The Turbulizer agglomerates and simultaneously mixes powders with a wide range of liquid levels. Jackets for heating and cooling are available. The company’s on-staff engineers can help define the properties of customers materials and show which method is most appropriate to achieve the best results.

Bepex International, Minneapolis, MN 612-627-1406 www.bepex.com

Mixer/Granulator

Mixer/Granulator

Suited for granulating, a mixer/granulator is equipped with tools that develop an intermediate-intensity mix action that is gentle yet thorough. When supplemented by high-shear devices (choppers), this action can quickly disperse minor liquid or powder ingredients. Both the plows and chopper shafts are mounted through air purge seals that maintain a small ingress of air around the shafts at all times, nearly eliminating the chance of any material getting into the seals.

Littleford Day Inc., Florence, KY 800-365-8555 www.littleford.com

Briquetter

Briquetter

The Elan B60 can briquet elastic-type feedstocks such as polyethylene and foams by using a special discharge device that heats the circumference of the briquets slightly, causing them to develop a skin that binds a feedstock that otherwise would fall apart in normal agglomeration. In addition to these types of feedstocks, various rigid foams and dust particulates, including nonferrous metals, can be briquetted. The unit is modular in construction and additional presses can be added to a common feed hopper. Fully automated, it requires little personal attention and is self-discharging. The briquet press uses modern positive piston hydraulics that are not susceptible to oil viscosity heating, allowing them to be used for long durations.

Briquetting Systems, Vancouver, BC, Canada 604-818-0287 www.briquettingsystems.com

You May Also Like