February 27, 2008

Flat-Bottom Bin Discharger

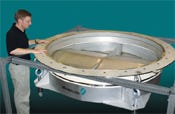

Flat-Bottom Bin Discharger

The Model 170-BD-30 bin discharger utilizes mechanically induced internal agitation to promote the discharge of dry solid ingredients from within a bin or hopper, typically for filling a feeder or to refill a weight-loss weigh feeder. The discharger is a self-emptying design with complete and total clean-out capability. It consists of a circular, nonconverging, flat-bottom housing containing a horizontally mounted agitator (driven from beneath) for effectively discharging dry solid materials from within the storage bin or hopper to which it is attached. Product flows out of the storage bin and into the mating wide-throat opening, where the sweeping action of the slowly rotating agitator across the discharger’s flat bottom produces positive product discharge without compaction, attrition, or segregation.

Acrison Inc., Moonachie, NJ 201-440-8300 www.acrison.com

Live Bottom-Bin Discharger

Live Bottom-Bin Discharger

A live bottom-bin discharger has a 10-cu-ft storage hopper to meter needles to the mixing process. The unit eliminates all bridging and provides even flow to an 8 × 48–in. twin-motor vibratory feeder. The entire system is supplied with dust-tight covers and dust boots. The self-contained unit can be made portable for moving from one area to another.

Metso BEST Inc., Brunswick, OH 800-827-9237 www.bestvibes.com

Flow Discharge Aid

Flow Discharge Aid

The Mucon Promo-Flow discharge aid is an easy-to-install solution to existing discharge problems. The custom-made, internally mounted screens are designed to transmit vibration directly into the product, preventing material bridging, rat holing, and segregation during discharge. The robust vibrators are mounted externally, activating the vibrating screens mounted on the inside of the silo wall at the points where the flow problem occurs. Rubber isolation mounts attach the discharge system to the silo, preventing leakage through the mounting holes. The whole unit is allowed to vibrate the product while contributing no vibration to the silo itself.

Kemutec Powder Technologies, Bristol, PA 215-788-8013 www.kemutec.com

Dished Head Bin Activator

Dished Head Bin Activator

Exclusive features of this bin activator include a dished head contour, a forged hanger suspension system, a patented beaded sleeve, and an oil-lubricated gyrator. The unit mounts under any existing round storage silo or square storage silo, whether the silo is concrete or steel. An available oil-lubricated gyrator is maintenance-free and guaranteed for 20,000 hours of continuous use.

Vibra Screw Inc., Totowa, NJ 973-256-7410 www.vibrascrew.com

Bin Aerators

Bin Aerators

These aerators solve a variety of bin flow problems associated with difficult powders. The product line consists of the Rectangular Air Pad, Evasser, and Flo-Pad products. These devices offer different shapes and pressure ratings and provide different methods of diffusing the air. They are alternatives to using high-impact pneumatic or electric vibrators that can be loud and cause damage to the bin and surrounding equipment. In fact, bin vibrators can pack material instead of fluidizing it to address the problem. Typically used in applications where the material flow into the bin is via pneumatic conveying, the entrained air in the material is evacuated during the settling of the powder material.

Monitor Technologies LLC, Elburn, IL 800-766-6486 www.monitortech.com

Controlled Rate Discharger

Controlled Rate Discharger

The SolidsFlow Model 6000 controlled rate discharger discharges materials that have the tendency to compact, segregate, and bridge. This unit helps eliminate these problems by controlling material flow with a uniquely designed feed tray that accommodates the flow characteristics of the product being discharged. The tray works with the material’s natural angle of repose to prevent any flow when the feed tray is turned off. There is no spillage and no run-on. High-frequency, horizontal motion applied to the feed tray produces a consistent, uniform flow. Feed rates up to 1500 cu ft/hr are attainable.

Schenck AccuRate, Whitewater, WI 800-606-9248 www.accuratefeeders.com

Vibratory Bin Activator

Vibratory Bin Activator

The Hula-Hopper is an improved vibratory concept based on operating principles proven in hundreds of installations. Within a single, extremely-low-headroom unit, material activation, infinitely variable flow rate control, and positive flow shutoff are combined. Installation, service, and operating costs are lower than bin activators of other designs and are backed by a 100% process guarantee.

General Kinematics Corp., Crystal Lake, IL 815-455-3222 www.generalkinematics.com

Bin Aerator

Bin Aerator

The Model K Vibra-Jet bin aerator can be installed on any storage silo, bin, or hopper as a versatile means of getting dry bulk materials, such as carbon black or fine cement, to gravity-feed more reliably at a low cost. Materials that tend to pack, bridge, or hang up can be made to flow freely and instantly on demand. A triple seal has been designed into the unit to prevent back feeding. This seal provides added reliability and extends the life of the unit.

Dynamic Air Inc., St. Paul, MN 651-484-2900 www.dynamicair.com

Bin Activator

Bin Activator

This bin activator instantly clears bins, hoppers, and other mass-flow vessels of compacted solids. It removes disruptive materials from channels, ducts, or recesses. The unit introduces multiple instantaneous sonic airbursts directly into compacted material to instantly restore flow, without severe shock and vibration methods that often damage equipment.

Pulsonics, Belleville, NJ 973-759-4025 www.pulsonics.com

You May Also Like