November 29, 2017

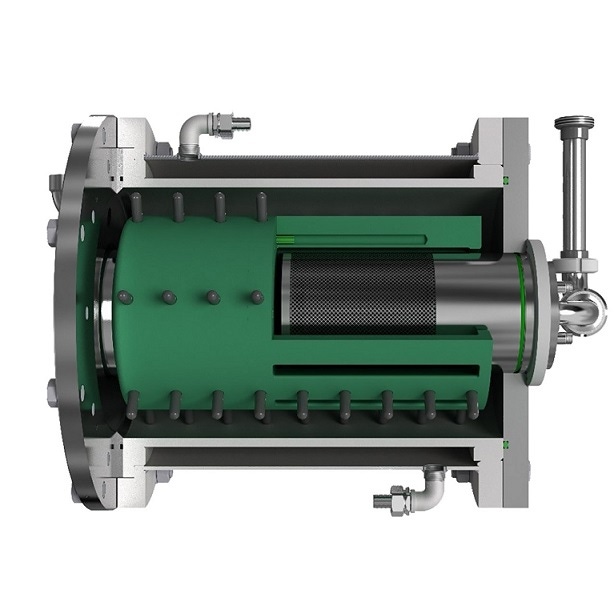

Compared to the traditional peg grinding system, several significant upgrades have been made with the Neos grinding system. A ceramic material with high wear resistance and maximum thermal conductivity is now standard for the inner liner of the grinding chamber. The agitator shaft was designed so, on one hand, the product exchange on available cooling surfaces has been improved due to the optimization of flow and, on the other hand, care was taken to ensure the maximum cooling surface is available for additional rotor cooling. The improvement to cooling efficiency is an essential aspect of the new design of the grinding system, since in many cases the power input to the grinding chamber is limited primarily by the temperature limits of the product. The spacing between the grinding chamber liner and the pegs on the agitator shaft was reduced. As a result, more intensive acceleration of extremely small grinding beads is possible. This leads to a considerably higher energy density, and thus to higher possible power input to the grinding chamber.

Netzsch Premier Technologies LLC, Exton, PA 610-561-6257 www.netzsch.com

For related articles, news, and equipment reviews, visit our Size Reduction Equipment Zone

Click here for a List of Size Reduction Equipment Manufacturers

You May Also Like