March 20, 2018

Traditional hammer mills work on the principle that most materials will crush, shatter, or pulverize upon impact. Material is fed into the mill’s chamber through the feed chute, and struck by ganged hammers, which are attached to a shaft that rotates at high speed inside the mill’s grinding chamber. The material is crushed or shattered by a combination of repeated hammer impacts, collisions with the walls of the grinding chamber, and particle on particle impact. The initial impact of the slow-moving particles against the high tip speed of the hammers produces the most significant size reduction. As the particles begin to reach the tip speed of the hammers, less reduction occurs because the energy transfer drops as the velocity differential levels out. Perforated metal screens or bar grates covering the discharge opening of the mill retain coarse material for further grinding until the particle size and approach angles are aligned, allowing properly sized materials to pass as finished product.

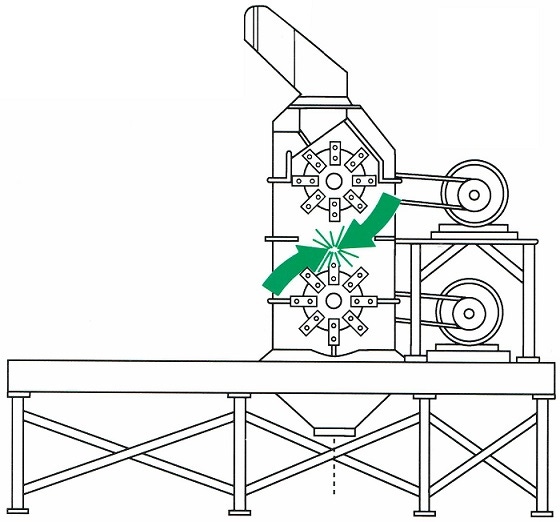

By contrast, dual-stage hammer mills are designed specifically to maximize space and efficiency by producing the finest possible end-product in just one pass. Dual stage mills feature two independently driven hammer mills stacked one over the other.

Attrition Zone

In a dual-stage hammer mill, there are really three phases of size reduction, due to what is known as the attrition zone. The attrition zone is the area created between the top rotor and bottom rotor of a dual stage hammer mill. Materials pass through the initial mill and screen arrangement and are then directed toward the secondary mill chamber. Before reaching the second rotor, particle-to-particle impact in the attrition zone creates additional opportunities for size reduction, in an area with principles similar to a jet mill. The turbulence created by the opposing rotors, and continuous stream of particles creates high impact forces; serving two purposes:

The reduction of large bulky materials to a fine and uniform consistency, with just one pass

The reduction of friable materials that are free flowing to an ultrafine particle size with one pass

In many situations, depending on materials and processing goals, materials are processed through a single stage mill, they are then screened and fed back into the mill for a second pass and additional processing. With this arrangement, a much larger mill may be required as it must process the virgin feed and the additional recirculating load of oversized particles.

It is important to note that multiple passes through a single-stage mill does not necessarily produce the same finished result as a single pass through a dual stage mill. Hammer mills are typically designed to have a short dwell time, meaning material is fed into, and evacuates the mill quickly; allowing material to be processed efficiently. By recycling pre-milled materials through the same screen over multiple passes, that material will not see the same impact forces as they will tend to pass through the screen quickly, already having been sized to clear the screen. Adding the second mill, with a smaller screen size, allows for a longer dwell time within the mill. Since the pre-milled product still must be reduced before passing the secondary sizing screen, material is suspended briefly so that a continuous feed rate will keep the attrition zone fully occupied with both coarse materials from above and finer particles working below.

Energy transferred from particle to particle impact, at very high speeds, produces the increased gradation at a finer particle range. This gradation is outlined in the table below. More size reduction occurs as significant energy is exchanged from the repeated collisions between particles and hammers, until the material finally passes through the secondary screen at the desired particle size.

Particle Size Analysis (see chart)

There are many variables in milling efficiency with fine particle size. A major factor is the screen selection for the top and bottom mills. Again, depending on the material properties, mills are equipped with bar grates or perforated screens; any combination can be employed. In cases where material is bulky, a bar grate may be selected for the initial milling to allow for higher wear resistance and durability against heavier materials. While the secondary mill will use a perforated screen with small bore diameter for finer finished particles. Screen size is the most influential factor relating to particle size, as the material must clear the screen.

Another variable is the rotor speed, as described in this article, the imposing force of the hammer to particle is what provides the size reduction. On a dual-stage mill, each mill is driven independently, such that they may rotate with the same tip speed, or the bottom mill may run at higher speed for fine grinding if outfitted by a variable frequency drive. This allows the user to fine tune the process and have more control over particle size distribution.

Finally, hammer style and size will contribute to the efficiency. The rotor can be assembled with many hammer configurations, selecting the right hammer configuration at the right tip-speed will produce the necessary impact force to correspond to the material being reduced without being knocked back during contact with the material.

Particularly, when dealing with fine grinding applications, air assist is another critical factor. Aspiration air is often employed to assist in efficiently drawing material through the milling chamber with the proper dwell time. Not only does the aspiration help produce more product uniformity, but also controls heat build-up and nuisance dust around the mill. By having dual stage processing contained in a streamlined system, the air path is simplified and prevents the need for multiple conveying steps with dust collection for a given system. Properly sizing the air system is critical, since the air flow through the mill must be carefully sized to capture only the ultra-fine dust, not to draw the material through the mill without allowing for the proper dwell time through each milling stage.

Bill Castine is sales engineer, Schutte-Buffalo, Buffalo, NY. For more information, call 716-855-1555 or visit www.hammermills.com.

You May Also Like