April 23, 2012

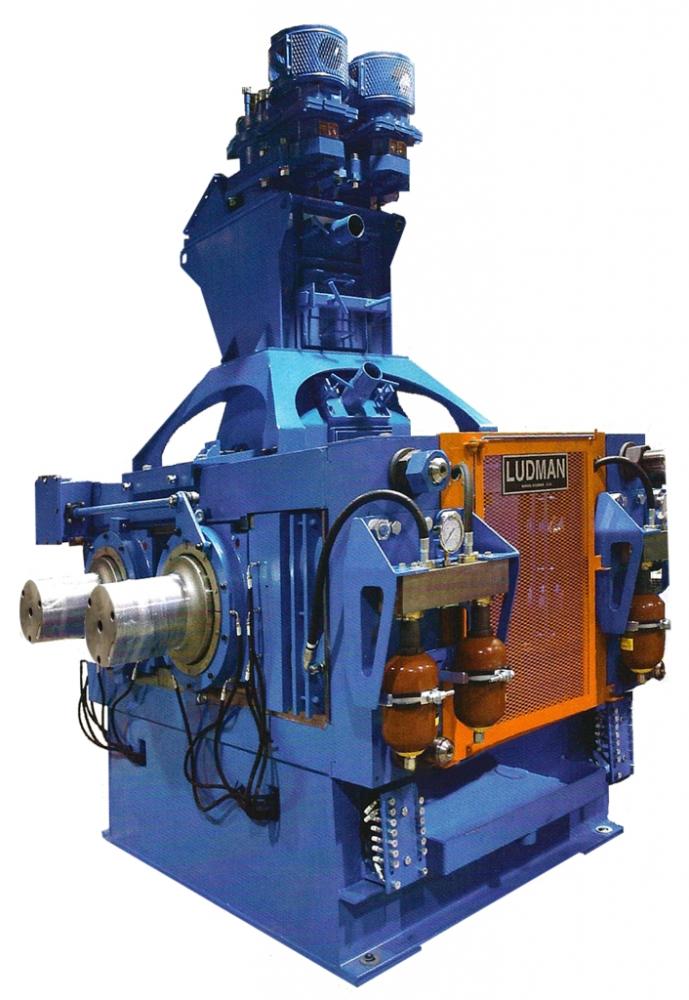

The Ludman roll compactor is designed to provide a low-cost, mechanical means to upgrade or convert undesirable fines by agglomeration into a salable granular product. The roll compactor is also used for the agglomeration of fines into flakes for pyroprocessing, increasing product bulk density, and controlling the product solubility rate. Features include: 12-44-in.-diam rolls; variety of roll materials; up to 800 tons separating force; up to 1700 HP drives; throughputs to 130+ tn/hr; force feeders or gravity feeders; flake breakers break compacted flake into less than 1.5 in.; fixed or variable speed drives. Typical material applications include: ammonium sulphate, burned lime, clay, copper concentrate, herbicide, mixed fertilizer, muriate of potash, phosphate rock, potassium sulphate, soda ash, sodium chloride, potash fines, sewage sludge, fgd gypsum, calcium hypochlorite, and rock salt. Ludman Machine Company LLC, Milwaukee, WI 414-431-3500 www.ludman.net

You May Also Like