April 27, 2018

On Wednesday, April 25, Stedman Machine Co. introduced a new hammer mill design at the 2018 Powder Show in Rosemont, IL.

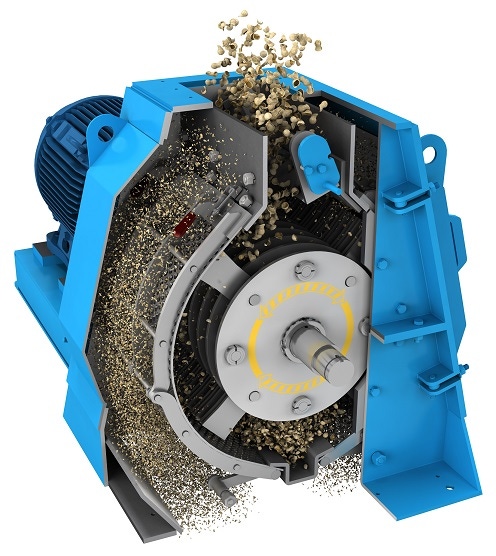

The new full circle design has higher throughput due to greater screen area. The screens fully enclose the rotor. The direct drive unit reduces the footprint of the hammer mill and motor combination which are mounted on an integral base.

Designed for grains, corn, fibrous bio-mass, and rendering, the mill is reversible to maximize hammer and screen wear. It features an externally adjustable intake diverter for feeding in either rotor direction. A turbulence channel at the base of the rotor interrupts particle flow to increase size reduction efficiency. Maintenance is easy with large access doors, quick release toggle clamps for drop-in screens with a hinged carriage.

The 22-in.-diam by 15-in.-wide rotor full circle hammer mill that was on display runs at 3600 rpm with a 75-hp motor. Capacity is dependent on application and screen selection. Screens are available in 1/8-, 1/4-, 3/8-, and 1/2-in. punch plate. Hammers have carbide overlays. Fabricated of heavy-duty plate steel, the unit will be available for product tests in Stedman's testing and toll processing facility, which includes air swept feed, product discharge, and cyclone separation capabilities.

Stedman Machine Co., Aurora, IN 812-926-0038 www.stedman-machine.com

For related articles, news, and equipment reviews, visit our Size Reduction Equipment Zone

Click here for a List of Size Reduction Equipment Manufacturers

You May Also Like