October 15, 2019

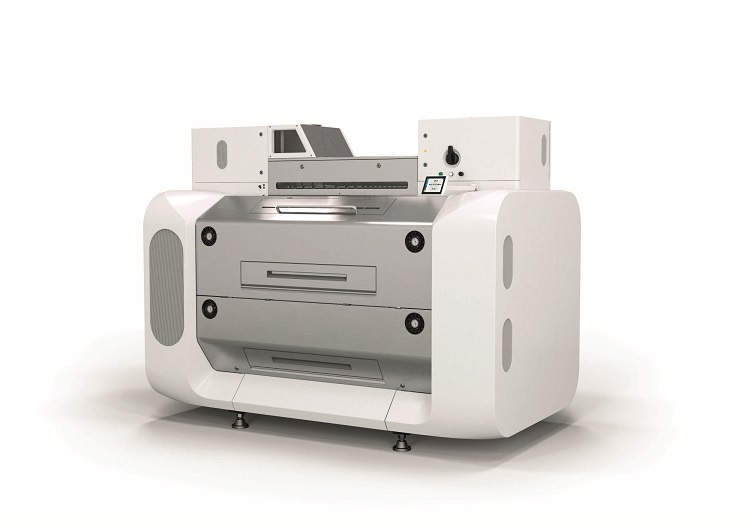

With Mill E3, Bühler revolutionizes the milling industry and sets new standards in cost-effective building investment, project realization time, and energy consumption.

“After the introduction of automation 40 years ago, Mill E3 is the next big step forward in milling,” said Johannes Wick, CEO of grains & food at Bühler Group.

The first customer to rely on Mill E3 also uses Bühler blockchain technology to trace grain for more transparency and food safety.

For decades industrial milling concepts have focused on optimizing machines and processes, but the basic design concept remained the same, based on buildings with a minimum of five to six floors. With the completely new approach of the Mill E3, Bühler now optimizes the entire arrangement and construction concept. At Networking Days 2019, Bühler showed that it is possible to build flour mills with the latest technology more cost-effectively, install them quicker, and operate them with less impact on the environment.

Shorter Installation Time, Faster Commissioning, Smaller Building

Mill E3 stands for advantages on three efficiency levels: space, time, and energy. In the optimal case a Mill E3 building can be 30% smaller in volume than a traditional mill of the same size. The construction of the Mill E3 building not only locks up less capital, it is also completed more quickly. By using pre-assembled modules, Mill E3 is installed 30% faster than conventional flour mills. "It's basically a plug-and-play mill," said Stefan Birrer, head of business area milling solutions. This means Bühler customers can set up their Mill E3s more quickly and start generating revenues faster. It significantly reduces infrastructure cost, construction time, and complexity.

Up to Ten Percent Less Energy

With the same output, Mill E3 reduces energy consumption by up to 10%, without compromising yield or quality. This is down to the compact mill design and innovative process solutions such as the newly developed integrated grinding system Arrius. Arrius has an integrated drive that saves up to 10% of energy compared to conventional roller mills. The Tubo tubular push conveyor replaces specific pneumatic transport passages to save energy. Tubo is more efficient and makes food production even safer. The product is transported gently, loses no weight due to drying out, and the conveyor system is more hygienic because the pipelines are self-cleaning.

"Be it space, time, or energy, on all these levels, we were able to show that the plant will be better than anything other mill builders have on the market," said Birrer.

"The design, the new grinding system Arrius, and the IoT and Blockchain applications are revolutionizing the milling industry once again," added Wick.

First Customer Uses Bühler Blockchain for Food Traceability

The UK’s largest milling company, Whitworths Holdings Ltd -- incorporating Whitworth Bros Ltd and Carrs Flour Mills Ltd -- operates 17 mills on nine sites. It is the first company to rely on Mill E3. "Besides the obvious mechanical benefits E3 offers, we were also convinced of the digitalization approach. Bühler is definitely on the forefront in this respect," said Mike Peters, managing director of Whitworth Bros Ltd "For us, Mill E3 offers more than just a new technology approach. It will enable us to create complete transparency for our customers in the future."

Together with Mill E3, Bühler has proposed increasing transparency along the value chain by adding connectivity features, digital services, and blockchain to help guarantee the end product quality.

Connected to the Bühler Insights Cloud

"With systems in place to trace the grain back to farms, Whitworth was in a good position to do a blockchain project," said Birrer. "What we have done is transform paper-based tracking into blockchain tracking.”

Mike Peters explains the reason behind the introduction of blockchain as follows: "If we don’t embrace these new digital technologies and embed them within our business now, in the longer term that could be a bar to entry into certain markets as pressure comes from the end consumer and eventually from regulators for increased transparency."

The new mill is due to be completed towards the end of 2020. After that the monitoring phase begins. "IoT and blockchain give us the opportunity to push the bar for food safety, food security, and transparency through our supply chain," said Peters.

Data from the fully connected mill will be monitored with Bühler Insights, Bühler's secure cloud service powered by Microsoft Azure. For milling companies that want to monitor and benchmark various production sites, Bühler has developed the digital service Yield Management System. It makes deviations between different recipes visible and comparable, from anywhere at any time. The Yield Management System is also connected to Bühler Insights.

Bühler AG, Uzwil, Switzerland +41 71 955 33 99 www.buhlergroup.com

Here are more size reduction-related articles that may interest you:

Jet Mill Application: Moisture-Sensitive Materials & Deagglomeration

The Best Ingredients and Equipment Make the Best Beer

You May Also Like