Improve your operations with sifters currently available in the market

August 13, 2021

Paul Van Camp, director of sales, Great Western Manufacturing

When it comes to the manufacturing of food products, quality is a brand’s number one priority. The last thing that any company or quality assurance specialist wants to hear is the R-word: Recall.

Today, quality assurance specialists are involved in setting the quality standards to which engineering teams must adhere when developing the equipment that maintains high-quality production. One of these critical pieces of equipment within the food processing industry is the production sifter. In food processing, there is a plethora of potential contaminants that can find their way into your product stream: from natural contaminants such as weevils, flour beetles, their larva and eggs, hair (human or animal), wood splinters and chips, bin scale, paper, string, sheet metal, bolts, and nuts. The list can go even further, but who really wants any of that in their food?

In any operation, the quality assurance department has three main considerations when comparing commercial grade sifters. These are classified as sifter types, screen types, and ease of inspections. Rest assured that many will claim they can meet your company’s volume, quality, and sanitation standards, but there is more to consider.

The goal of this article is to educate you and help improve your operations with what is currently available in the market.

Sifter Types

As a quality assurance specialist, how confident are you that the sifter you have is the right one for the job? The sifter is vital to removing as many contaminants as possible from your food stream process. Today, you may have multiple different sifters in your manufacturing process. Let’s review how each sifter type is utilized in a dry powder process such as flour, starch, sugar, salt, corn meal, etc.

Today the market has three popular sifter classification types:

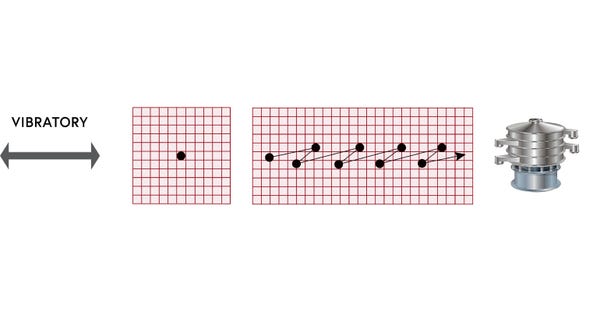

1. Vibratory – This type of machine uses a circular or linear motion with a vertical component.

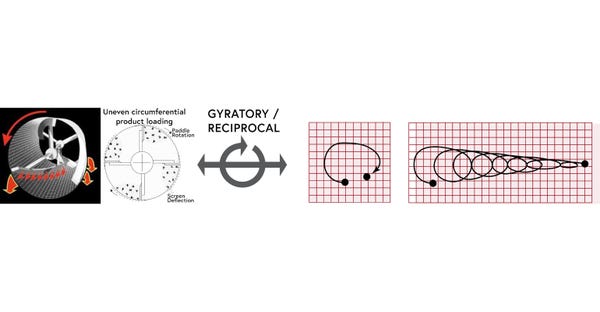

2. Centrifugal - Force and rotary motion

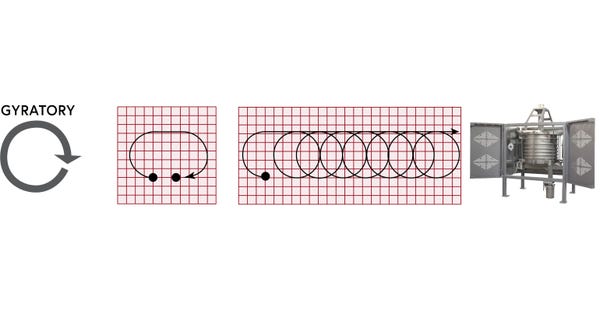

3. Gyratory - uses a circular horizontal motion

Vibratory Sifters

Vibratory sifters are considered to be low-cost sifters. Equipped with one or two vibration motors, eccentric masses on the lower and upper ends of the motion-generating component vibrate the machine around its center of gravity. These units are primarily utilized in single-pass, low-volume operations: 50 lb or less at one time. This makes the vibratory sifter an economical choice, which provides a relatively low-cost entry point.

The simplicity of the vibratory sifting action and single pass screening makes the vibratory sifters economical. The vertical component of the vibratory motion causes the product to lose contact with the screen for a significant time while inside the machine. This reduces the product recover efficiency, screen efficiency, and directly affects the process yield on a per screen area on a per product flow rate basis. Discrepancies in screening efficiency can have exponential effects as production flow rates increase and must be monitored closely. Therefore, vibratory sifters commonly provide a solution for small, single-pass operations, but are not ideal for continuous flow systems. If you are just beginning sifting and have low-capacity demands, this may be a solution for you.

Vibratory force of motion

Centrifugal Sifters

Centrifugal sifters were initially developed for wastewater treatment plants to break up (de-lump) solids and push them through a screen. Today, centrifugal sifters are the second most preferred sifter type in the food industry. Not only are these compact machines space-effective, but their design is user-friendly -- both simple to operate and to maintain.

The centrifugal sifter is designed to forcibly break down clumps that can be found in certain material types such as flour, sugar, salt, starch, etc. However, because the systems are not designed to identify the differences between good product and waste, there is the potential that contaminants will be broken up into smaller particles which also pass through the cylindrical screen, directly into the finished product.

AIB and BISSC Standards 4.1.4.3 states specifically that “sifters shall employ no rubbing action to facilitate product flow.” Most centrifugal sifters manufactured today have a paddle or similar mechanism that forces product through a sifter screen, in direct contrast to the AIB and BISSC standard. To get around this standard, most centrifugal sifter paddles are slightly off the screen as to not rub. However, the paddles still tend to break contaminates into particles small enough to pass through the screen, instead of separating the contaminates from the main product flow.

The centrifugal sifter is not suitable for processing fragile materials, as it may have more difficulty maintaining the desired product quality. The vigorous screening action can cause the paddle to derogate the fragile materials, creating an unacceptable change in particle size distribution. Additionally, the high relative velocities created between the material and the screen causes a higher percentage of good product to divert into the tailing canister.

A centripetal force, generated by high-speed rotations

Gyratory Sifters

Gyratory sifters set industry standards for quality and sanitation. Independent operator tests confirm gyratory sifters filter contaminants better than any other sifting technology (vibratory/centrifugal). The nature of gyratory motion, aided by the sifter’s increased separation capabilities allow removal of these contaminants, while maintaining high product volume capacity. For commercial sifting operations, gyratory sifters offer more throughput, with improved capture of contaminants.

The gyratory sifting method is the favored means of sifting product by top quality control management teams. The gyratory sifter provides the highest degree of reliability in finding contaminants prior to entering the final product stage.

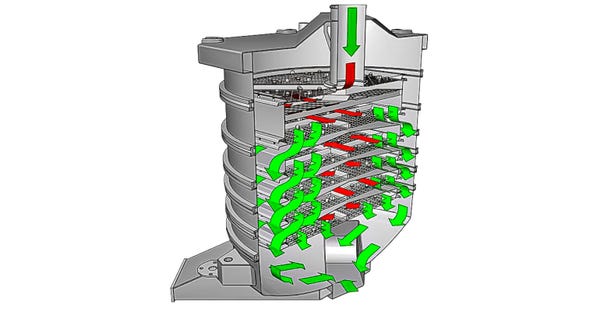

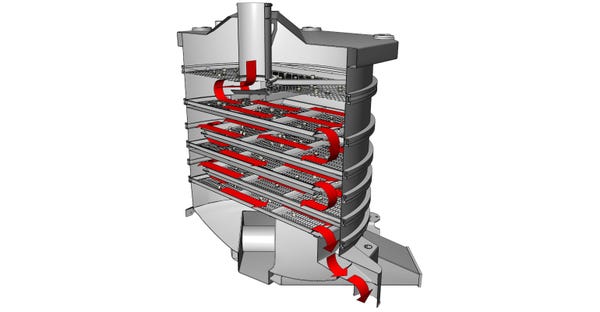

With its purely horizontal motion, a gyratory sifter can have multiple screens in the same machine with the same screen mesh size, where the product actually flows different directions. This allows for significantly more screen area in a machine’s overall footprint than in any other type of machine

A gyratory force of motion

Gyratory sifters produce a horizontal gyratory sifting action, ideal for scalping, grading, or fines removal from dry free-flowing powders. This sifting motion retains material longer, has a slower and more gentle sieving action, and minimizes vertical agitation. These attributes keep the fine material in contact with the screen longer, giving maximum opportunity for the material to pass through without the aid of extraneous force, leading to more accurate separations. This is depicted below in the gyratory product flow.

Gyratory - good product material path

Gyratory - oversized material path

Sifter Screen Types - Sanitation

Though not widely recognized, there are screen quality advantages based on which type of sifter is operating. Every user must determine their unique requirements for screen type, depending on the necessary quality tolerance and screening efficiency requirements. The most effective way to determine screen size and type for your requirements is through sample testing in a laboratory setting.

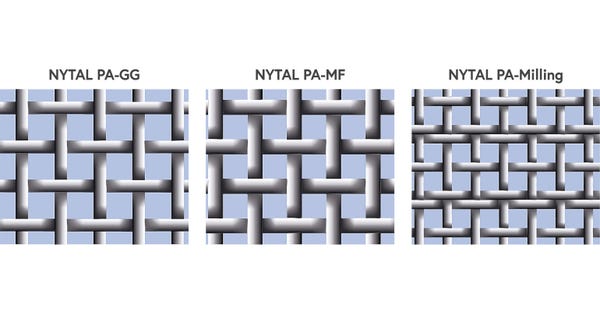

Numerous sifter manufacturers offer market-leading fabric technology in the milling & food industry. The range of materials available include synthetic (nylon or polyester) and wire (metal mesh) fabrics for efficient screening at each stage of your process. All screen fabrics must comply with current FDA and EU regulations. Some common mesh types are depicted below.

NYTAL PA-GG, NYTAL PA-MF, NYTAL PA-milling

Commonly, thread types for gyratory and vibratory sifters have wire or nylon mesh sieve with square openings which allow particles to pass through. These screen types are used more frequently than others, as they tend to be sturdier and less expensive. Screen grids, which are less commonly used, have openings that can be round, square, or rectangular, depending on operational needs and quality expectations.

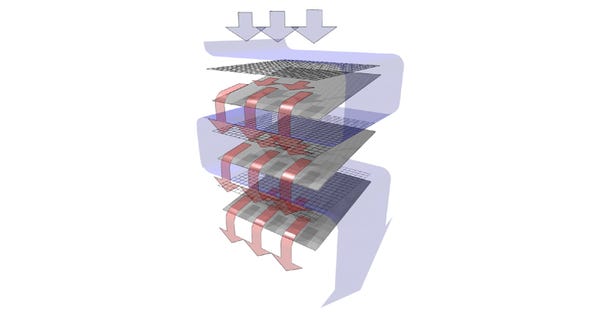

Typically, sieves are stacked with particle openings of gradually diminishing size as the product descends through the sifter (as indicated below). Dry sieving begins with a solid feed--typically powder--that enters the sieve stack at the top sieve. Aided by gravity, solid particles pass through the sieves until they eventually fall onto a sieve screen with openings too small for them to pass through. Finally, the material on each sieve is recorded, and material with the desired particle size range is retained. Other material can then be recycled and re-processed until the correct particle size is achieved. This is depicted below with the purple highlighted flow path.

The flow path in a centrifugal sifter is similar to the gyratory sifter noted above. In a centrifugal sifter, material is fed into a chamber with a perforated screen on the outside walls. The product is pushed using rotors, to the outside screen. Consequently, the larger material is left to carry over while the smaller material passes through the screen as finished product.

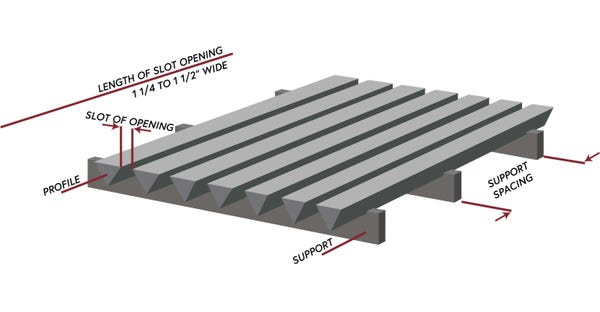

Centrifugal sifters typically incorporate wedge wire-type screen with 1¼-1½ in. width. Wedge wire screen is a welded screen designed to be highly durable and resistant to clogging. While requiring a higher initial investment, they typically see a long service life.

As depicted above, wedge wire screens are meant for high-capacity separation on large particles, especially those found in solid/liquid separation. When it comes to small contaminants, this is not the screen of choice. The ability for small particles to pass within these 1¼-1½-in. wire slots is the number one issue with these types of screens. When it comes to very fine separations, woven screen is preferred to wedge wire. While it admittedly has a shorter typical service life, woven screen can offer separations down to approximately 0.005 mm vs. wedge wire’s minimum of 0.03 mm. For wedge wire, fabrication options are typically limited, due to welding requirements and weight. In contrast, woven wire mesh provides a greater degree of flexibility in fabrication and application.

Screen type in different sifters is highly dependent upon application. Centrifugal sifters typically require the high durability of a wedge-wire or perforated type screen, especially considering that the welded construction is most commonly available in a cylindrical shape. Vibratory and gyratory sifters more commonly use woven mesh screen. While screen mesh depends upon the product in the flow, screen material choice for durability is affected by capacity size and material abrasiveness. For high capacities of finer materials, the gyratory sifter can have over 1,200 square feet of screening area. Careful choice of woven screen mesh can maximize results at this capacity.

Screen Materials

Besides consideration of screen type, the material also plays a role in the screening process.

Non-metallic screens are advantageous for maintaining a longer service life and present a lower risk of contamination should screen degradation cause lost pieces to incorporate into the product flow. For quality assurance purposes, woven synthetic mesh screens can present a lower risk of product contamination than that which is presented by metal screen degradation.

Stainless steel woven mesh screens are preferred for processing materials with a higher oil content, such as corn or oats. However, as the screen unavoidably degrades, metal strands can come loose, and contaminate the product stream. These pieces of wire are small, and difficult to detect/catch, even with the most advanced equipment. Metal screens typically experience a shorter service life due to the repetitive movement of the screening process plastically deforming and gradually causing dislocations within the metal. Because of this, wire screens require more frequent maintenance and re-screening.

Sifter Inspections

Due to the material’s zig-zagging flow and subsequent horizontal and vertical action, vibratory sifters require frequent inspection of screen tension, as low tension can reduce screening capacity. Cleaners, used to dislodge near sized particles or sticky, finer powders from the screen, are not as effective in vibratory sifters, due to the lesser amount of energy and vertical movement that the vibratory motors can impact upon them. This can cause the screen to be susceptible to blinding. Therefore, it is necessary to check for this during inspections. Vibratory sifters lose efficacy with sifting product because it is not always kept in contact with the screen, due to the vibratory motion of the unit. Frequent screen blinding indicates either that the product’s particles are too near sized for the screen selected, or that the material is too sticky for the cleaners to effectively keep the screen clear.

The time required to inspect a vibratory sifter screen is typically less than six minutes.

Centrifugal sifters require significantly more screen inspection than any other sifter type. Because the material is forcibly pushed through the screens, these sifters experience a significant increase in screen wear and eventual failures. In turn, this creates a greater dependence on the maintenance of screen tensions in order to ensure adequate screen longevity. With rotating paddles, if the wire screens do fail, the failure is often severely catastrophic. Especially for this reason, screen inspections for centrifugal sifters should be carried out after each batch run, or on a daily basis to inspect for screen wear, damage and any other quality control items established by your company.

With hourly or daily inspections, the opportunity for contaminants to enter the product flow is greatly increased. But because forced material presents such an increased risk of screen failure, these inspections are a necessity to your operations. The time required to check a centrifugal screen is typically less than six minutes.

When determining the frequency with which inspections will need to take place, you must consider the quality of the sifter, screen material, material flows, and material coarseness.

Gyratory sifters require significantly less screen maintenance. Because the product material moves gently across and through the screens, the sifter not only minimizes wear, but also maximizes the amount of good material that is separated from what ends up in the tailings overflow.

Conclusion

As you can see, there are many different types of sifters, each operating with unique properties and requirements. Each sifter will return different results based on your material size requirements and contamination opportunities. How often to inspect sifters prior to screen failure may be based on product flow/mix, abrasiveness, cloth type, and machine type. Typically, your best practice will provide you an average frequency mean time to failure. Your company’s maintenance records should provide a baseline that quality assurance specialists can manage. Today you face higher stakes when considering sifter type, screen materials, and quality control processes. After all, who can really afford a recall?

Paul Van Camp is director of sales, Great Western Manufacturing (Leavenworth, KS). For more information, call 913-682-2291 or visit www.gwmfg.com.

You May Also Like