Enhancement improves peak magnetic performance for magnetic separators

October 19, 2021

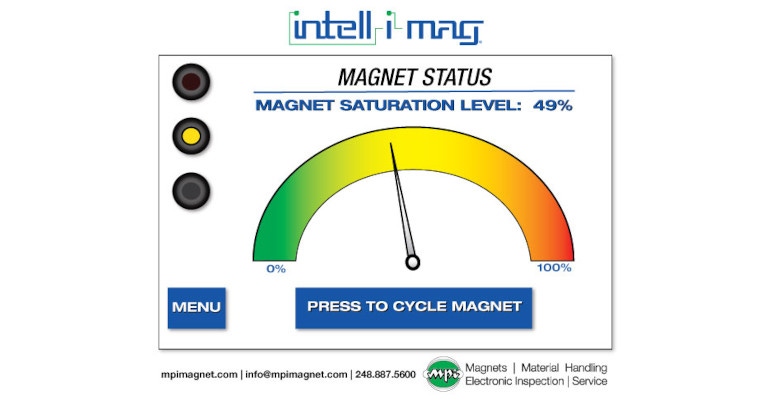

Magnetic Products Inc. (MPI) introduces the patented Intell-I-Mag, an advancement in magnetic separation innovation and factory automation designed for the food production and other industries.

Intell-I-Mag is the first smart magnet with self-monitoring of ferrous metal saturation in real time, providing operators key information to help improve the cleaning and maintenance of the magnetic separators needed to maintain peak magnet performance during production.

Intell-I-Mag delivers is a solution for manufacturing facilities impacted by industry-wide labor shortages and cost increases. It also helps reduce challenges due to equipment failures, inadequate magnet cleaning intervals, or inaccessible magnetic separation equipment. Data-driven feedback on cleaning cycles and magnet performance increases production line “up time” and promotes peak performance of magnetic separators, reducing the risk of a metal event.

“Plant operators need to be aware of metal saturation levels at all times,” said Keith Rhodes, MPI founder, CEO and Intell-I-Mag inventor. “Intell-I-Mag is the first magnet with smart technology that talks to you. Its magnetic separator detects discrepancies with metal buildup and alerts staff before an incident can occur.”

MPI’s patented new technology aligns with Industry 4.0 and Internet of Things trends, using sensors and data collection to improve analysis of magnetic separator performance, including magnet saturation, cleaning alerts, temperature monitoring, cleaning cycles, and position location. Intell-I-Mag’s sensors monitor tramp metal saturation levels and once the magnet reaches the designated level, it alerts plant personnel of required cleaning or the engagement of automated self-cleaning processes. Alert limits can be set by the designated personnel responsible for magnet system performance and password protected.

With Intell-I-Mag’s real time feedback on separator performance, operators can also establish a higher level of metal control and create a stronger quality management plan for programs such as HACCP, ISO, BRC, IFS, and SQF. Using the new technology, vendors can be monitored in real time during materials unloading and metal events detected earlier to reduce damage. In addition, finishing separators prior to packaging allows separators to operate at peak performance, while improving protections from a potential recall due to metal. Ensuring separators are operating at peak performance also increases the facilities’ ability to capture lightly ferrous metal, such as work hardened stainless steel. Finally, Intell-I-Mag improves customer reporting with the addition of performance data on the magnetic separator.

The Intell-I-Mag smart magnet controller is available exclusively on MPI magnetic separators. Available models include plate magnets, drawer magnets, chute magnets, liquid magnets, and pneumatic magnets. Controllers are rated for appropriate installation environments, including washdown and hazardous locations.

Magnetic Products Inc., Highland, MI 248-887-5600 www.mpimagnet.com

About the Author(s)

You May Also Like