October 16, 2019

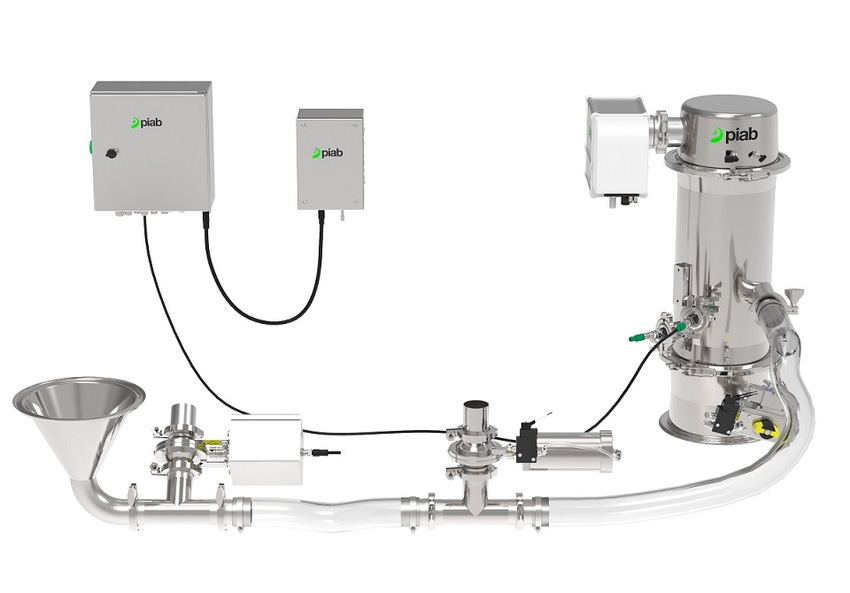

Productive industries rely on state-of-the-art intelligent systems to boost their processing capacity. Vacuum conveying plays a vital role in the manufacturers’ production lines, especially within the food and pharmaceutical sectors. So, how do you make the humble vacuum conveyor smarter? The simple answer is by giving it a brain and senses.

To act intelligently, machines, like humans, need a brain and senses. The brain and the sensory system to which it is connected enable us and machines to learn. Machine-learning is central to the development of advanced production systems.

The Brain Controls the Heart

In a vacuum conveyor, an electrical control unit will act as the brain, automatically controlling the vacuum pump at the heart of the conveyor. Being in charge of the pump enables the conveyor’s “brain” to adjust the flow of materials to perfectly suit both the properties of the conveyed material itself and certain environmental conditions that may affect the production, such as temperature and humidity.

An integrated air carrying unit will automatically set the carrying air ratio and then continuously adjust this during the entire cycle.

Using a Sensory System

The electrical control unit needs a cleverly configured system of sensors to perform the correct adjustments, altering settings to improve the conveyor’s overall performance. Strategically placed vacuum and pressure sensors send electrical signals to the control unit, where these signals are converted to pneumatic ones. These are in turn used to stop or start the vacuum pump, and to open and close valves in the conveying system. Level sensors are used to guard against overfilling and to monitor the emptying process.

Using Smart Software

Coupled with smart software based on advanced algorithms, the conveyor’s sensory system and brain will be smart enough to quickly learn to adapt and re-configure the conveying system when performance related changes occur. Its machine-learning ability enables it to be completely self-optimizing.

With an anti-blockage function built into the software, the system will be able to feel when blockages are building up in the pipeline. Valves will then open automatically to let more air into the system, preventing the blockage before it causes any real problem.

Faster Changeover

The performance of conventional vacuum conveyors is manually adjusted and optimized by an operator. A self-optimizing conveying system will make the same adjustments several times faster than can be achieved by even experienced operating staff. As a result, changeover from one material to another--or indeed from one batch of material to another--will be much quicker in a smart, self-optimizing vacuum conveyor than in a conventional one, saving time and money in every cycle. This is particularly advantageous for processors handling many different materials or those that need to make frequent changes, such as food manufacturers.

More Reliable Changeover

A self-optimizing system is also more reliable, as it avoids any risk of human error. As the complexity of production lines increase, so do errors due to inexperience among operators or misinterpretations of performance parameters. In a self-optimizing system, calibrations are no longer relying on rules of thumb or the dexterity of fingers. Instead, the machine-learning process ensures a flawless flow of materials in all circumstances and at speeds that perfectly correspond to specific applications. Parameters are adjusted regardless of the diameters of pipelines or conveying lengths, instead all adjustments are made according to what is needed at that precise moment and then checked again every four seconds.

A Friendly Co-Worker That is Easy to Maintain

No matter how intelligent the system is, human interaction will still be necessary. User-friendly touch screens help operators to learn and work with a smart conveying system, ensuring the system is utilized to its full potential. In addition, the installation of smart conveyors needs to be straightforward and intuitive. A smart conveyor should be viewed upon as an intelligent, trustworthy, and friendly co-worker that will help free up time, allowing operators to focus on other tasks.

A smart, self-optimizing vacuum conveyor will also make sure that it stays sharp and in shape. During each conveying cycle, the sensors it relies on for optimal functionality will be automatically cleaned by a shock of air. The intelligent control unit will also make sure no blockages appear in the system by adjusting the clearing of any vertical pipeline sections at the end of each suction cycle. Together, such anti-blockage and air-assisted cleaning functions will ensure a long service life for the conveyor and its filters. It results in a smart vacuum conveying system that requires only minimal amount of maintenance.

Summary

Give a vacuum conveyor a “brain and senses” and it will become smart enough to self-optimize, achieve faster changeover, and improve productivity. Contradictory as it may sound, the smart choice between a conventional vacuum conveyor and an intelligent one really is a no-brainer.

Milan Bratt is product manager vacuum conveying division, Piab. Piab provides smart solutions for the automated world, helping end users and machine producers in e-commerce logistics, food, pharma, automotive, and other manufacturing industries to improve energy efficiency, productivity, and working environments. For more information, call 800-321-7422 or visit www.piab.com.

Here are more articles that may interest you:

Why Pneumatic Conveying Best Satisfies the 6 Additive Manufacture Powder Handling Requirements

Pneumatic Conveying through Inclined Pipe

Supply Meets Demand with Continuous Powder Processing System

You May Also Like