January 14, 2010

Tri-Lobe Blower Packages

Kaeser’s complete line of vacuum systems includes the Com-paK Plus blower series. These positive-displacement, tri-lobe blower packages provide consistent, reliable vacuum with heavy-duty construction and low noise levels. They deliver flows to 3305 cfm and vacuum to 15 in. Hg. The complete, customized packages include inlet and discharge silencers, a high-efficiency, EPAct compliant TEFC motor and an automatic v-belt tensioning device. The complete package offers lower pulsations and reduced footprint. Kaeser Compressors Inc., Fredericksburg, VA 800-777-7873 www.kaeser.com/omega

Kaeser’s complete line of vacuum systems includes the Com-paK Plus blower series. These positive-displacement, tri-lobe blower packages provide consistent, reliable vacuum with heavy-duty construction and low noise levels. They deliver flows to 3305 cfm and vacuum to 15 in. Hg. The complete, customized packages include inlet and discharge silencers, a high-efficiency, EPAct compliant TEFC motor and an automatic v-belt tensioning device. The complete package offers lower pulsations and reduced footprint. Kaeser Compressors Inc., Fredericksburg, VA 800-777-7873 www.kaeser.com/omega

Vacuum Pneumatic Conveyor

The MiniVac features side access for easy filter inspection and changeover. It provides efficient operation by retaining product within the process through the use of an adjustable pulse-jet filter cleaning system. A side-mounted regenerative blower provides a powerful vacuum pressure and self-contained operation. The entire package is compact and lightweight, yet heavy-duty in design, with performance capacity ranges up to 10,000 lb/hr. Units can be easily disassembled for cleaning and are available in standard industrial, food grade, sanitary, and pharmaceutical models. The MiniVac can be easily combined with Hapman’s line of product handling equipment for accurate batch weigh systems. Hapman, Kalamazoo, MI 800-427-6260 www.ideasthatmove.com

The MiniVac features side access for easy filter inspection and changeover. It provides efficient operation by retaining product within the process through the use of an adjustable pulse-jet filter cleaning system. A side-mounted regenerative blower provides a powerful vacuum pressure and self-contained operation. The entire package is compact and lightweight, yet heavy-duty in design, with performance capacity ranges up to 10,000 lb/hr. Units can be easily disassembled for cleaning and are available in standard industrial, food grade, sanitary, and pharmaceutical models. The MiniVac can be easily combined with Hapman’s line of product handling equipment for accurate batch weigh systems. Hapman, Kalamazoo, MI 800-427-6260 www.ideasthatmove.com

Batch Weigh Vacuum Convey System

This batch weigh vacuum convey system can be used in the food, pharmaceutical, or chemical industries. It is designed to deliver powders and granules to process vessels with accuracies within 0.5% of the batch size. This type of vacuum convey system allows for greater control of product quality and inventory control of materials. Material can be conveyed from drums, bags, or super sacks. Vac-U-Max, Belleville, NJ973-759-4600 www.vac-u-max.com

This batch weigh vacuum convey system can be used in the food, pharmaceutical, or chemical industries. It is designed to deliver powders and granules to process vessels with accuracies within 0.5% of the batch size. This type of vacuum convey system allows for greater control of product quality and inventory control of materials. Material can be conveyed from drums, bags, or super sacks. Vac-U-Max, Belleville, NJ973-759-4600 www.vac-u-max.com

Pneumatic Air-Vey Magnets

Air-Vey magnets remove ferrous contaminants from products in dilute-phase pneumatic conveying systems operating at 15 psi or less. These units are used to ensure product purity and protect process equipment. The flow through area of the housing is engineered to maintain the same product velocity with no appreciable drop in pressure. The magnets easily install in horizontal, vertical, or angled positions with compression type couplings or weld in place. Inside the stainless-steel housing is a powerful cylindrical shaped magnet with a cone shaped nose. As material enters the housing, the nose cone diverts the material around the cylindrical magnet where it passes through the magnetic field and ferrous contaminants are drawn to the magnetic surface. Ferrous contaminants are safely held in place as the cleaned product exits out the opposite end of the housing. Puritan Magnetics Inc. Oxford, MI 248-628-3808 www.puritanmagnetics.com

Air-Vey magnets remove ferrous contaminants from products in dilute-phase pneumatic conveying systems operating at 15 psi or less. These units are used to ensure product purity and protect process equipment. The flow through area of the housing is engineered to maintain the same product velocity with no appreciable drop in pressure. The magnets easily install in horizontal, vertical, or angled positions with compression type couplings or weld in place. Inside the stainless-steel housing is a powerful cylindrical shaped magnet with a cone shaped nose. As material enters the housing, the nose cone diverts the material around the cylindrical magnet where it passes through the magnetic field and ferrous contaminants are drawn to the magnetic surface. Ferrous contaminants are safely held in place as the cleaned product exits out the opposite end of the housing. Puritan Magnetics Inc. Oxford, MI 248-628-3808 www.puritanmagnetics.com

Transporters

These transporters are designed to handle abrasive, fragile, sticky, and high-temperature materials in a pneumatic conveying system. The transporter receives material from supplies and then conveys to one or more locations. All transporters are shipped fully assembled and tested. Inlet and outlet valves are installed, compressed air piping is completed to a single air connection, and all electrical solenoids, level controls, and pressure transmitters are wired to a terminal strip in a junction box. Whirl-Air-Flow, Big Lake, MN 800-373-3461 www.whirlair.com

These transporters are designed to handle abrasive, fragile, sticky, and high-temperature materials in a pneumatic conveying system. The transporter receives material from supplies and then conveys to one or more locations. All transporters are shipped fully assembled and tested. Inlet and outlet valves are installed, compressed air piping is completed to a single air connection, and all electrical solenoids, level controls, and pressure transmitters are wired to a terminal strip in a junction box. Whirl-Air-Flow, Big Lake, MN 800-373-3461 www.whirlair.com

Heavy-Duty Pump

The Fuller-Kinyon pump is ideal for conveying fine powders without risk of blowback. A material seal is formed when product is forced against the counterweighted flapper valve preventing convey-air leakage back through the screw. One moving part means less maintenance and reliability in the most demanding environments. The pump operates with lines pressures up to 30 psig. Features include heavy-duty construction, ease of maintenance, design simplicity, cost effectiveness, ability to handle high capacities, fuel efficiency, and low power consumption. FLSmidth, Bethlehem, PA 610-264-600 www.flsmidth.com

The Fuller-Kinyon pump is ideal for conveying fine powders without risk of blowback. A material seal is formed when product is forced against the counterweighted flapper valve preventing convey-air leakage back through the screw. One moving part means less maintenance and reliability in the most demanding environments. The pump operates with lines pressures up to 30 psig. Features include heavy-duty construction, ease of maintenance, design simplicity, cost effectiveness, ability to handle high capacities, fuel efficiency, and low power consumption. FLSmidth, Bethlehem, PA 610-264-600 www.flsmidth.com

Dense-Phase Pneumatic Conveying System

A key feature of this dense-phase conveying system is the exclusive air management system. By using a pressure control regulator, airflow control orifice, and bypass valve, total air flow to the system and product-to-air ratio are automatically controlled at the vessel. When air flow and product-to-air ratio are not accurately controlled, boosters or trace air lines are required. Not only are they expensive to purchase and install, but will add air to the system. Added air creates higher energy requirements and increased line velocity. Smoot, a division of Magnum Systems, Kansas City, KS 800-748-7000 www.magnumsystems.com

A key feature of this dense-phase conveying system is the exclusive air management system. By using a pressure control regulator, airflow control orifice, and bypass valve, total air flow to the system and product-to-air ratio are automatically controlled at the vessel. When air flow and product-to-air ratio are not accurately controlled, boosters or trace air lines are required. Not only are they expensive to purchase and install, but will add air to the system. Added air creates higher energy requirements and increased line velocity. Smoot, a division of Magnum Systems, Kansas City, KS 800-748-7000 www.magnumsystems.com

Pressure Blowers

To fill the need for greater pressures and volume, Chicago Blower developed a series of high-capacity blowers to fulfill higher filtration requirements for dense solid media. The blowers convey a variety of materials, as well as cool and aerate, and are especially suited for the most advanced pollution control systems. Features include a lightweight aluminum alloy wheel designed to reduce motor loads and decrease vibration. Chicago Blower Corp., Glendale Heights, IL 630-858-2600 www.chicagoblower.com

To fill the need for greater pressures and volume, Chicago Blower developed a series of high-capacity blowers to fulfill higher filtration requirements for dense solid media. The blowers convey a variety of materials, as well as cool and aerate, and are especially suited for the most advanced pollution control systems. Features include a lightweight aluminum alloy wheel designed to reduce motor loads and decrease vibration. Chicago Blower Corp., Glendale Heights, IL 630-858-2600 www.chicagoblower.com

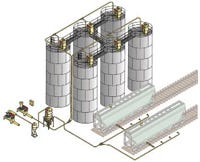

Dual-Blower Railcar Unload System

The vacuum-pressure rail unload system unloads powder, pellet, and granular material from railcars at conveying rates in excess of 100,000 lb/hr. Using separate vacuum and pressure blowers, the system unloads material from the railcar at higher conveying rates and for longer conveying distances. A vacuum blower draws material from the railcar to a self-cleaning filter receiver that separates the product from the conveying air. Mounted below the receiver is an Aerolock rotary valve that meters the product into the pressure side of the system for final delivery to storage. Dual-blower systems are available in 3–10-in. line sizes and include a control panel, properly-sized blowers, railcar adapter kit, and hoses. K-Tron Process Group/K-Tron Premier, Salina, KS 785-825-1611 www.ktronprocessgroup.com

The vacuum-pressure rail unload system unloads powder, pellet, and granular material from railcars at conveying rates in excess of 100,000 lb/hr. Using separate vacuum and pressure blowers, the system unloads material from the railcar at higher conveying rates and for longer conveying distances. A vacuum blower draws material from the railcar to a self-cleaning filter receiver that separates the product from the conveying air. Mounted below the receiver is an Aerolock rotary valve that meters the product into the pressure side of the system for final delivery to storage. Dual-blower systems are available in 3–10-in. line sizes and include a control panel, properly-sized blowers, railcar adapter kit, and hoses. K-Tron Process Group/K-Tron Premier, Salina, KS 785-825-1611 www.ktronprocessgroup.com

Blower Package

The Qube blower package features the new Qx blower and is a quiet, low-cost, quick-delivery pneumatic conveying solution. The Qube is highly efficient to reduce overall costs, has a compact footprint to reduce space requirements, and is enclosed in a powder-coated steel enclosure to reduce noise even further—24 dBa attenuation. Additional features include an integral check valve, discharge from back, and a discharge flexible connector. Tuthill Vacuum & Blower Systems, Springfield, MO 800-825-6937 www.tuthill.com

The Qube blower package features the new Qx blower and is a quiet, low-cost, quick-delivery pneumatic conveying solution. The Qube is highly efficient to reduce overall costs, has a compact footprint to reduce space requirements, and is enclosed in a powder-coated steel enclosure to reduce noise even further—24 dBa attenuation. Additional features include an integral check valve, discharge from back, and a discharge flexible connector. Tuthill Vacuum & Blower Systems, Springfield, MO 800-825-6937 www.tuthill.com

Pneumatic Line Housing

IMI introduces the pneumatic line housing (PLH). Instead of a single, center-flow cartridge circuit, the PLH incorporates a series of 1-in. diam. 50 MGOe Rare Earth tubes on staggered centers. This ensures that all product has repeated contact with the magnets. The holding strength of the bullet magnet has been improved with a newly introduced stripper collar that is used to wipe metal contamination from the magnet. Industrial Magnetics Inc., Boyne City, MI 231-348-5730 www.magnetics.com

IMI introduces the pneumatic line housing (PLH). Instead of a single, center-flow cartridge circuit, the PLH incorporates a series of 1-in. diam. 50 MGOe Rare Earth tubes on staggered centers. This ensures that all product has repeated contact with the magnets. The holding strength of the bullet magnet has been improved with a newly introduced stripper collar that is used to wipe metal contamination from the magnet. Industrial Magnetics Inc., Boyne City, MI 231-348-5730 www.magnetics.com

Induction-Hardened Bends

This induction hardening system produces abrasion-resistant bends that outlast mild steel by up to six times. Designed to improve the bottom line by providing a longer, more reliable service life, these bends offer a highly abrasion resistant inner wall hardened to 600 Brinell with a ductile outer wall a 250 Brinell. Made to conform to standard pipe sizes, end options include almost any configuration available for stand pipe. Ultra Tech Pipe, Port Washington, WI 800-626-8243 www.ultratechpipe.com

This induction hardening system produces abrasion-resistant bends that outlast mild steel by up to six times. Designed to improve the bottom line by providing a longer, more reliable service life, these bends offer a highly abrasion resistant inner wall hardened to 600 Brinell with a ductile outer wall a 250 Brinell. Made to conform to standard pipe sizes, end options include almost any configuration available for stand pipe. Ultra Tech Pipe, Port Washington, WI 800-626-8243 www.ultratechpipe.com

Regenerative Blowers

Patented TT regenerative blowers feature tri-stage technology. Vacuums to 17 in. Hg and pressures over 12 psi can now be obtained with the low noise levels of regenerative blower technology. All blowers are backed by a three-year warranty. FPZ Inc., Saukville, WI 262-268-0180 www.fpz.com

Patented TT regenerative blowers feature tri-stage technology. Vacuums to 17 in. Hg and pressures over 12 psi can now be obtained with the low noise levels of regenerative blower technology. All blowers are backed by a three-year warranty. FPZ Inc., Saukville, WI 262-268-0180 www.fpz.com

Pneumatic Conveying Systems

Each of this company’s 16 pneumatic conveying concepts has it own set of operating characteristics for pressure, conveying line velocity, efficiency, and performance. Because each material to be conveyed reacts differently under a given set of operating conditions, it is critical to match the system operating characteristics to the material to be conveyed in order to achieve the most desired conveying performance and to provide the best value. Each system has the ability to convey at almost any conveying velocity desired to suit a given material to be conveyed. Conveying capacities range from just a few hundred pounds of material per hour up to 500 tn/hr, with conveying distances exceeding 6000 ft. Dynamic Air Inc., St. Paul, MN 651-484-2900 www.dynamicair.com/systems.html

Each of this company’s 16 pneumatic conveying concepts has it own set of operating characteristics for pressure, conveying line velocity, efficiency, and performance. Because each material to be conveyed reacts differently under a given set of operating conditions, it is critical to match the system operating characteristics to the material to be conveyed in order to achieve the most desired conveying performance and to provide the best value. Each system has the ability to convey at almost any conveying velocity desired to suit a given material to be conveyed. Conveying capacities range from just a few hundred pounds of material per hour up to 500 tn/hr, with conveying distances exceeding 6000 ft. Dynamic Air Inc., St. Paul, MN 651-484-2900 www.dynamicair.com/systems.html

Dense-Phase Pneumatic Conveying System

The dense-flow system differs from many of its competitors with the absence of air boosters along the pipeline. This system can achieve equal or greater results in many instances without the use of boosters. Some of the advantages to not having boosters include lower air consumption, lower installation costs, less maintenance, less “wear and tear” on the system, and less spare parts inventory. The system simplifies complex conveying problems. J.D.B Dense Flow Inc., Palm Harbor, FL 800-822-3569 www.jdbdenseflow.com

The dense-flow system differs from many of its competitors with the absence of air boosters along the pipeline. This system can achieve equal or greater results in many instances without the use of boosters. Some of the advantages to not having boosters include lower air consumption, lower installation costs, less maintenance, less “wear and tear” on the system, and less spare parts inventory. The system simplifies complex conveying problems. J.D.B Dense Flow Inc., Palm Harbor, FL 800-822-3569 www.jdbdenseflow.com

Pneumatic Screw Pump

The pneumatic screw pump is a heavy-duty dry materials injection pump designed to feed dry pulverized material into a pneumatic conveying line. It can handle highly abrasive, friable, or very fine powders. Unlike rotary airlocks that require tight clearances to seal against conveying air, this pump uses the material to form the seal. Other benefits include increased conveying rates with less air, no blowback, even when running empty, increased wear resistance to abrasive materials, low profile, longer bearing life with fewer system shutdowns, and overall reduced operating and maintenance costs. Wm. W. Meyer & Sons Inc., Libertyville, IL 800-963-4458, www.wmwmeyer.com

The pneumatic screw pump is a heavy-duty dry materials injection pump designed to feed dry pulverized material into a pneumatic conveying line. It can handle highly abrasive, friable, or very fine powders. Unlike rotary airlocks that require tight clearances to seal against conveying air, this pump uses the material to form the seal. Other benefits include increased conveying rates with less air, no blowback, even when running empty, increased wear resistance to abrasive materials, low profile, longer bearing life with fewer system shutdowns, and overall reduced operating and maintenance costs. Wm. W. Meyer & Sons Inc., Libertyville, IL 800-963-4458, www.wmwmeyer.com

You May Also Like