Korsch introducies a tablet press for chemical products with large formats, deeper filling depths, and higher compression forces.

July 20, 2020

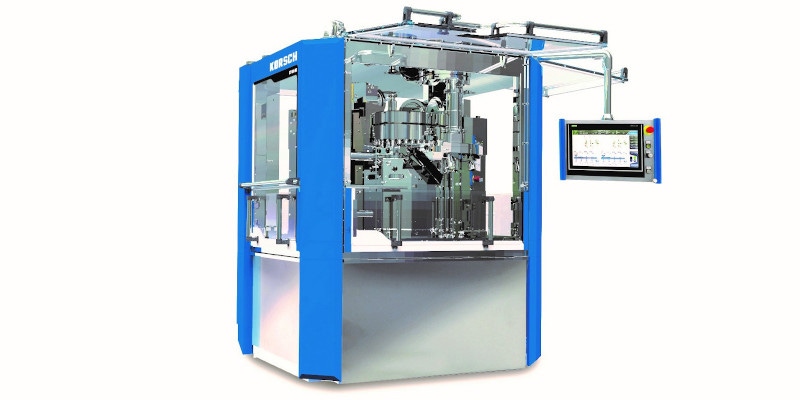

Korsch is introducing a tablet press specifically developed for technical and chemical products with large formats, deeper filling depths, and higher compression forces.

Available in the fall of 2020, the XT 600 HD double rotary tablet press combines key facets of the company’s proven technology in a cost-effective platform. Its design maintains the company’s exchangeable turret feature, and offers high-speed production capabilities for both single-layer and bi-layer tablets.

Among other applications, the XT 600 HD has proven effective in the production of salt tablets, catalysts, detergents, and fertilizer tablets. The high-capacity feeding system and robust compression column design deliver high tablet quality and production output.

Complete with the “on the spot” punch lubrication system and optimized dust extraction, the XT 600 HD is designed for extended, continuous operation, and provides premium efficiency in a 24/7 production environment. Both the precompression and main compression columns can deliver 120 kN of compression force – sufficient even for the most difficult-to-compress products. The compression dwell bar extends consolidation time and improves output with difficult products.

Korsch America Inc., South Easton, MA 508-238-9080 www.korsch.com

About the Author(s)

You May Also Like