November 30, 2017

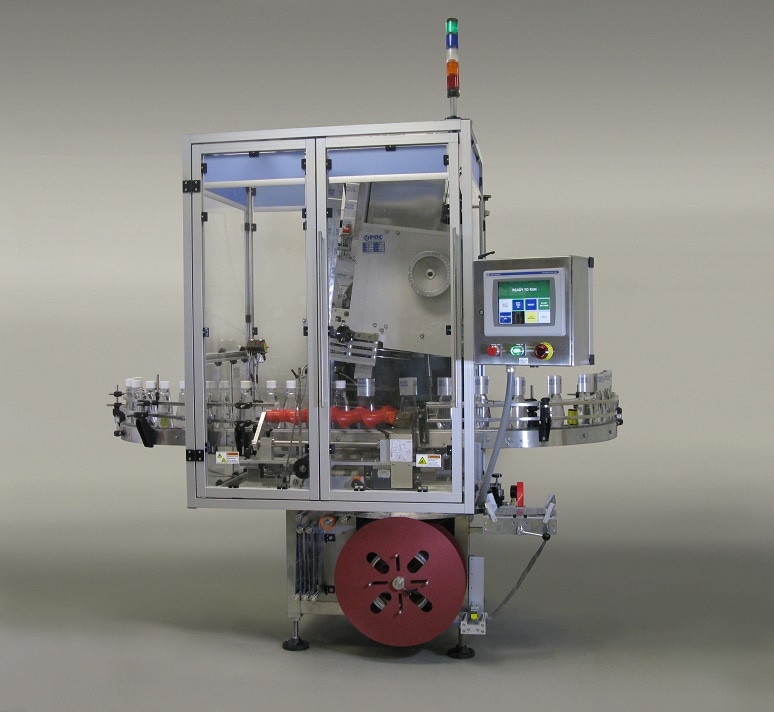

PDC International Corp. has re-introduced a shrink sleeve applicator/bander that operates at up to 400 cpm, and handles a broad range of applications, including bottled and jarred foods, pharmaceuticals, and products with irregular shapes or inconsistent sizes, such as candles and syringes.

The new 75C-E shrink sealer has two proprietary technology advantages. The first is The IndexingTooling technology, a film management system that precisely handles sleeving material through feeding, cutting, and application with high consistency. The second is a cutting blade assembly that is an alternative to the spinning knife configurations that are standard in the packaging industry.

PDC’s patented blade assembly is engineered for precision cutting and perforating. It delivers precise, clean cuts for months, even under continuous high-speed conditions. Blades can be re-sharpened repeatedly, and many are double-edged. Double-edged blades are reversible, so one set provides extraordinary service life. The proprietary blade design translates directly into packaging appearance, less machine downtime, and longer intervals between blade replacements.

This shrink sealer is compatible with standard and sustainable films, including PVC, PETG, OPS, and PLA, including thin gauge (1.25 mil/30 micron) material. The system applies banding material .375 to 3 in. in diameter and .625 to 4 in. high for tamper-evident banding and shrink labeling.

The 75C-E is a robust shrink sealer built to UL standards and engineered for continuous operation. It is manufactured in the U.S. and uses readily available, off-the-shelf components to minimize total cost of ownership and prevent unscheduled downtime.

PDC International, Norwalk, CT 203-853-1516 www.pdc-corp.com

Get information on the 2018 Powder & Bulk Solids Conference & Exhibition

You May Also Like