May 18, 2020

SPX Flow announces a new, cost-effective, and efficient solution to meet the growing demand for high-quality beverages with particles such as wheat, oats, rice, nut pieces, or fruit.

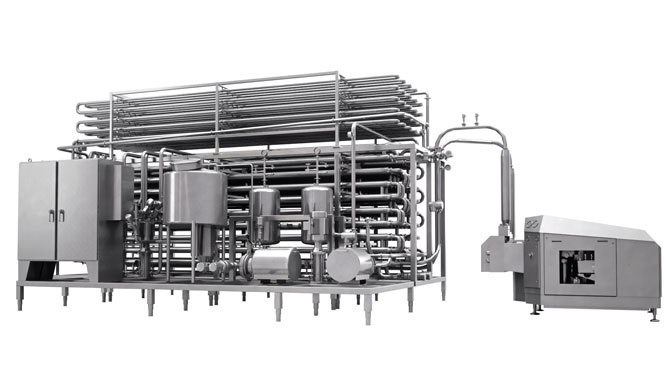

Based on Tubular UHT technology, this drinkable grains solution provides a single process line solution with up to 40% less cost than alternative processing methods.

The SPX Flow system requires just one aseptic tank and one UHT skid. It produces a compact, low-cost installation with optimized energy usage, reduced CIP, and minimized waste. As the system uses a tubular UHT technology, it can handle much larger particle sizes than traditional methods. This design ensures a gentle process that protects them from damage or maceration. This ensures a thicker, more nutritious, premium quality final product.

“We are always trying to find new ways to help our customers innovate, drive sustainability, reduce costs, and enhance quality,” said Allan Hurup Vangsgaard, global product manager UHT systems at SPX Flow Inc. “Our drinkable grains solution offers a great opportunity to meet the consumer demand for high-quality products in this area.”

A single processing line provides a simpler, more compact production method than traditional dual line concepts used for processing beverages with fruit, nut, or grain particles. Grains are added in-line after the homogenizer and the liquid and particles are then continuously mixed together before being processed through the UHT system. The design ensures blending accuracy and stability for consistent, high-quality results.

“Our drinkable grains solution offers an easy way to meet this exciting new trend in dairy and non-dairy beverages,” said Vangsgaard. “The system has been designed based on our long experience in dairy processing and in-depth understanding of the application needs. The blending accuracy and stability produced makes this a winning solution for producers.”

SPX Flow Inc., Charlotte, NC 704-808-3000 www.spxflow.com

You May Also Like