April 12, 2018

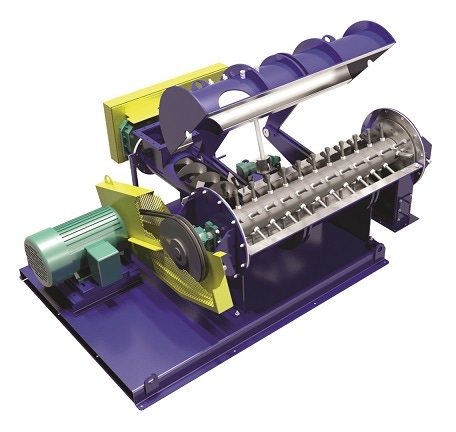

Pin and paddle mixers are two mixing and blending models used for processing a wide range of materials.

Paddle mixers, also known as pug mills, are optimal for various applications, including heavy-duty mixing and conditioning. They use a kneading and folding over motion to thoroughly blend materials. Paddle mixers are commonly used for processing materials such as municipal sludge, fly ash, and FGD sludge, as well as foundry dust, pigments, and even fertilizers and agricultural chemicals. Paddle mixers can be used as stand-alone units, or as a complement to a disc pelletizing system.

Pin mixers use high-speed, rotational forces to blend, mix, and condition fine materials. They are often used for processing materials such as limestone, bentonite clay, coal dust, flue dust, and many others. Much like the paddle mixer, pin mixers can act as stand-alone units, or as part of a disc pelletizing configuration.

Feeco International, Green Bay, WI 920-468-1000 www.feeco.com

You May Also Like