July 26, 2019

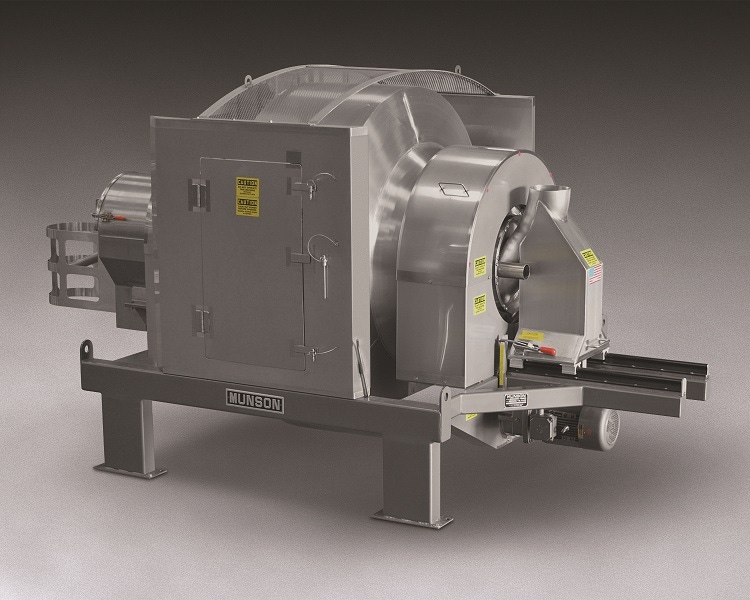

This new model 700-TH-40-SS sanitary rotary batch mixer with internal spray line distributes liquid additions throughout dry solids in one to three minutes with total uniformity and minimal shear or heat.

The spray line can introduce coatings, flavorings, vitamins, or active ingredients in liquid form into any bulk solid food, nutraceutical, chemical, or mineral product.

Proprietary mixing flights within the rotating drum fold, tumble, cut, and turn the material, which recombines 288 times per minute and creates a wide bed of moving material onto which liquids can be sprayed in trace amounts or large quantities for rapid incorporation. The flights also direct the material toward and through a stationary, pneumatically-actuated plug gate valve for total discharge, eliminating residual that would otherwise be wasted or require manual removal prior to cleaning.

Twin doors on opposing sides of the mixing vessel and a sliding intake chute provide unobstructed access to the interior, intake spout, and seal area for cleaning, sanitizing, and visual inspection of all material contact surfaces. An internal supply line allows in-place rinsing and cleaning.

Constructed of stainless steel finished to sanitary standards, the mixer has a useable batch capacity of 40 cu ft, total capacity of 82 cu ft, and is equally effective in blending of batches from 100 percent of rated capacity to as low as 15 percent without liquid additions, and to 33 percent with liquid additions.

The rotating drum is supported by two oversized trunnion rings that ride on heavy-duty alloy roller assemblies, providing long life with minimal maintenance. The design eliminates the need for an internal shaft with seals contacting material. To contain dust, the machine has one seal at the inlet, which is mounted externally to allow rapid, inexpensive replacement.

Munson Machinery Company, Inc., Utica, NY 800-944-6644 www.munsonmachinery.com

Here are more articles that may interest you:

Mixer Selection: 3 Tips for Success

Benefits of Tumble Blenders and Dryers

You May Also Like