January 24, 2019

When solids are dispersed or dissolved into liquid, the relative amounts of each phase are necessarily key factors in mixer selection. In reality, viscosity is an even more important parameter. For the purpose of our discussion in this article, let’s define percent solids as the ratio of solid mass present in a formulation, with “solids” pertaining to the non-volatile materials or the inorganic components of the mixture.

While the term “high solids” is commonly used across different markets including adhesives, sealants, paints, and coatings, there are no standards defining the minimum or average solids content of high solids formulations in general.

Percent Solids vs. Viscosity

Depending on the chemistry of the raw materials, high solids compositions take on a wide range of viscosities. For example, solvents with good solvency and low-molecular weight polymers are used to obtain low viscosity and acceptable flow in sprayable high solids coatings. Even some 100% solids hot-melt adhesives are almost water-like in viscosity during processing at the appropriate temperatures. Conversely, a gel formulation containing only 5% solids can be unpourable and behave like a semi-solid.

Therefore, mixer selection is generally dictated by viscosity rather than percent solids. The starting viscosity of the solvent or liquid base, the maximum viscosity reached by the mixture during processing, and the final viscosity of the end product (if different from maximum viscosity) are all vital considerations which must be shared with your mixer manufacturer.

Single-Shaft Mixers

Conventional single-shaft mixers such as propellers and turbines can be capable of preparing high solids formulations in the low viscosity range. These are economical machines suitable for solids that readily incorporate into liquid with only gentle agitation or stirring action. However, for solids that resist wet-out, for instance hydrophobic powders added into water, low-speed agitators become very inefficient. To accelerate dispersion or dissolution of such solids, higher energy devices such as saw-tooth dispersers and rotor/stator mixers enable shorter lead times.

Running at tip speeds around 5000 ft/min, a properly designed saw-tooth disc-style disperser creates vigorous flow within the mix vessel. It generates a vortex into which solids can be added for quick incorporation into the batch. Dispersers are typically used in applications up to around 50,000 cP in viscosity.

In comparison, a rotor/stator mixer typically features a four-blade rotor running at tip speeds in the range of 3000-4000 ft/min within a close tolerance fixed stator. This type of device creates mechanical and hydraulic shear by continuously drawing product into the rotor and expelling it radially through the openings in the stator. Because of the restriction provided by the stator, this mixer offers higher shear but less pumping capacity than an open-disc saw-tooth disperser blade. For the same reason, its viscosity limit is lower – around 10,000 to 20,000 cP. The rotor/stator mixer is available in both batch and inline designs.

Powder Induction Systems

When large amounts of powders need to be added in bulk, or when hard-to-disperse solids take too long to completely wet out even with a high-speed blade, a mixer with built-in powder injection capability is worth considering.

In earlier powder injection systems, a pump would propel the liquid stream into an eductor, creating a vacuum. Powders fed through an overhead tube would be drawn by this vacuum into the eductor where it joined the liquid flow. The resulting ‘pre-mix’ moved on to a rotor/stator mixer which then applied shear and mixing action, breaking down agglomerates and transporting the mixture downstream. In its day, this system offered a useful tool for powder induction. The inline system eliminated the floating solids problem of batch systems, and it offered a more precise control over the mixing process. But this set-up also presented some serious limitations. With three separate devices in series, maintenance — in terms of labor, required expertise and spare parts — was intensive. Balancing the performance of the pump, educator, and mixer was often difficult, and in many applications, downtime was quite high.

Today’s inline rotor/stator mixers with integral powder injection capability are more operator-friendly and low-maintenance in design. These new generation high shear mixers no longer require the use of centrifugal pumps or eductors to create the suction for powder injection. Shear levels are comparable to a standard rotor/stator but the mixer’s ability to combine solids and liquids right at the region where intense mixing takes place makes a significant impact on dispersion quality. Furthermore, it eliminates the need to add powders directly into the tank which could be a dusting and safety issue. Material handling is simplified because the inline mixer is installed at floor level and powders are added at a more practical height just above the mixer. Operators no longer must climb up mezzanines carrying heavy bags of powder. Sample applications include magnesium hydroxide slurries of up to 65% loading and titanium dioxide pigment dispersions containing 70% solids.

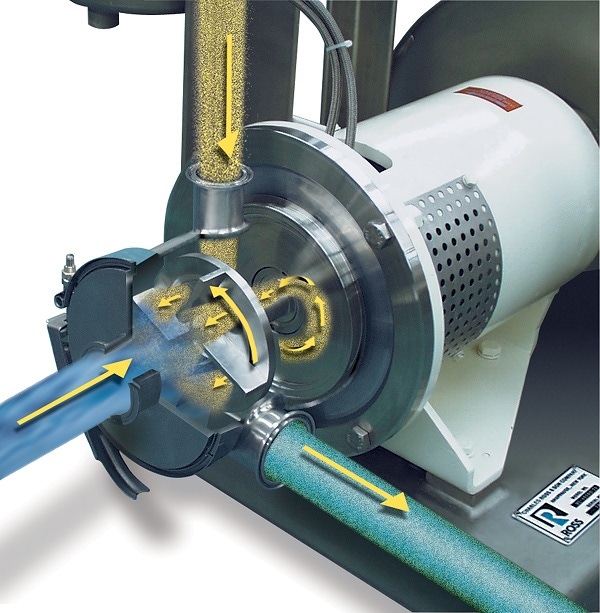

See Figure 1. How a powder induction mixer works: the liquid stream (blue) enters the mixer and immediately encounters the powder addition. Drawn by a powerful vacuum, free-flowing powders (yellow) are injected into the liquid and instantaneously mixed under high shear. The resulting dispersion (green) is expelled centrifugally through the stator openings at high velocity.

Multi-Shaft Mixers

Products that undergo viscosity changes peaking well over 50,000 cP are typically batched in multi-shaft mixers. The most common configurations include dispersers and rotor/stators used in combination with a low-speed anchor agitator. The anchor agitator helps to exchange materials from different parts of the vessel, essentially “feeding” the high-speed devices with product that would otherwise not flow towards it. The wings of the anchor agitator also normally include adjustable scrapers for wiping the vessel bottom and sidewalls. This ensures tighter temperature control in addition to enhanced product turnover.

Aside from the extended capability of multi-shaft mixers from a viscosity standpoint, another design advantage is that they are closed systems that offer the benefit of vacuum mixing. When processed under vacuum, certain formulations develop better properties as a result of improved shearing and contact of the different components.

With its independently-driven agitators, a multi-shaft mixer is highly versatile for processing highly-filled pastes and suspensions with a wide viscosity profile from start to end of the batching cycle. Sample applications include: sunscreen lotions; hot-melt adhesives; low-VOC-coatings; high-solids wood fillers, grout, and caulking compounds.

See Figure 2. Triple-shaft mixer configuration consisting of a three-wing anchor, a high speed shaft with two disperser blades and a four-blade rotor within a slotted stator head.

Planetary Mixers

As viscosity climbs higher and higher, approaching 500,000 cP or so, depending on how slippery or sticky the product behaves, turnover within a multi-shaft mixer will eventually start to suffer and affect the mixing efficiency. If the motors don’t overload, localized overheating may occur around the high-speed disperser blade, or the anchor agitator will begin carving a path through the viscous batch. The logical solution is to utilize a set of agitators that moves through the batch regardless of product flow. This is the forte of planetary mixers. In a planetary mixer, two or more blades rotate on their own axes as they orbit on a common axis. Modern double planetary mixers equipped with helical blade can now handle viscosities as high as 6 million cP or more. There are also hybrid planetary mixers consisting of a planetary stirrer and a high speed disperser blade that revolve on their own axes while orbiting the vessel. As both agitators constantly advance into the batch and fresh product, any heat build-up is evenly distributed. Solids are quickly incorporated into a viscous liquid base and stubborn agglomerates are dispersed even as the batch has become barely “flowable”. Shear levels and flow patterns are easily fine-tuned because the agitators are individually-controlled. Sample applications include dental composites, thick film inks, pigment dispersions in wax, highly-filled silicone sealants, and polymer solutions.

See Figure 3. A hybrid planetary mixer equipped with a high-speed disperser and helical planetary stirrer. After mixing, the vessel is rolled over to the discharge station. A platen is lowered hydraulically into the vessel, forcing product out and into pails positioned under the raised platform.

Sigma Blade Mixers

Extremely viscous materials are processed in kneaders, also called double arm sigma blade mixers. These are horizontal mixers composed of two z-shaped blades that rotate toward each other at differential speeds. The blades pass the trough walls and each other at close clearances, providing a shearing and tearing action on the product. The trough of the mixer is then tilted to discharge the finished product. Kneader extruders combine the efficiency of a conventional double-arm sigma blade mixer with the convenience of an extrusion screw for discharging heavy and viscous materials. The discharge screw is located in a separate cavity just below the z-blades and helps feed batch material into the mixing blades. When the mixing/kneading cycle is complete, the screw rotation is reversed to extrude the product out through a discharge opening or die. Sample applications include high-temperature gasket materials, mortar mixes, mastic sealants, rubber compounds, and masterbatches.

Christine Banaszek is sales manager at Charles Ross & Son Co. (Hauppauge, NY), manufacturer of specialty mixing and blending equipment. For more information, visit www.mixers.com.

For related articles, news, and equipment reviews, visit our Mixers & Blenders Equipment Zone

Click here for a List of Mixer & Blender Manufacturers

You May Also Like