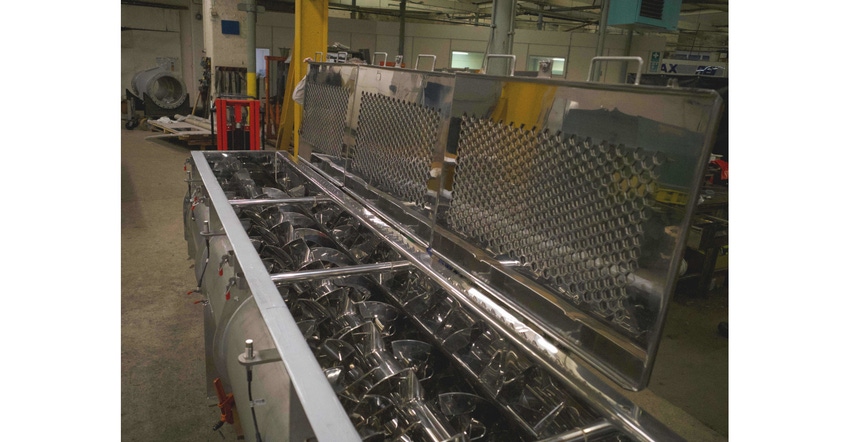

Design of the new stainless steel continuous mixer provides more than twice the material throughput than previous Ajax mixers.

February 24, 2023

Ajax Equipment has supplied a leading global food company with a heated continuous mixer to expand the production of one of the world’s leading brands of cereal bar.

The design of the new stainless steel continuous mixer provides more than twice the material throughput than the mixers Ajax has previously supplied this customer.

The machine includes a range of Ajax’s mixing technologies including Lynflow paddle flights on the twin augers to provide efficient mixing to a variety of ingredients. The casing’s special profile and hot water jacket help maintain material temperature, consistent ingredient condition, and thorough mixing, while still allowing access for inspection and cleaning via its hinged covers.

Food production requires a standard of hygiene. To aid this the mixer’s casing includes an internally mirror polished “crack- and crevice-free” finish, while the machines profile ensures there are no “dead” areas where material can build up. To enable “clean-in-place” the mixer is able to hold water, allowing the machine to be part filled and run to aid cleaning of the screws.

“Many ingredients commonly used in cereal bar production are sticky and when left to their own devices prone to build-up,” said Eddie McGee, managing director, Ajax Equipment. “Ajax’s Lynflow flights are designed to prevent this, and when combined with special profile, minimizes material build-up, reducing the need for cleaning downtime.”

About the Author(s)

You May Also Like