April 29, 2019

Robust apron conveyors (SZFs) are used in cement plants to transport clinker safely and economically from the kiln cooling system to the silos. Beumer Group offers a variant, the belt apron conveyor (GSZF).

Using a belt instead of a chain as traction element allows higher speeds and a slimmer design while still delivering the same level of performance. The GSZF is therefore particularly suitable for modernizations.

In general, the clinker comes out of the cooler at 80°+ ambient temperature. But during the process, a so-called kiln flash can occur caused by a raw meal flash from the preheater tower or by caked clinker coming off the kiln: Within a few seconds several tons of raw meal or clinker shoot through the cooler. The material to be conveyed cannot cool down sufficiently and reaches the conveyor at temperatures of 500 to 800°.

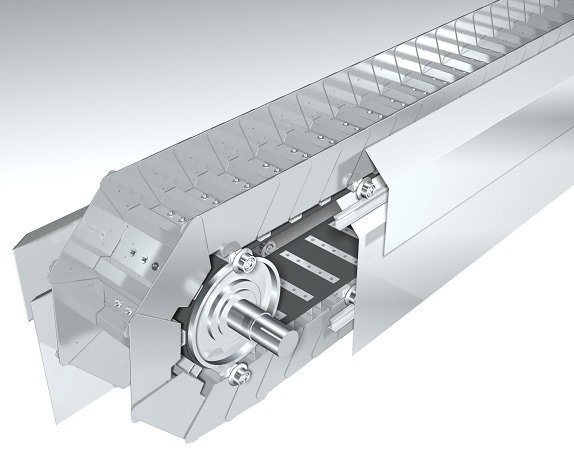

The specific design of the cells allows safe, low-friction transportation of any hot material. Sealed and overlapping side walls and bottom plates in the cells prevent the clinker from exiting and minimize the escape of dust. The traction element in this conveyor is usually a single or double strand sprocket chain. The system supplier is the only manufacturer on the market who offers apron conveyors with the tried and tested Beumer steel wire belts from the bucket elevator technology instead of a chain as traction element. Here the cells are attached to the long-lasting, steel-wire reinforced belt in a way so that the heat of the clinker in the steel cells is not transferred to the belt. Partition plates are attached in the feeding area below the cooler and can be easily removed for maintenance, protecting the belt against hot clinker in case of a kiln flash.

With speeds of 0.6 m/sec, the conveyor can reach double the conveying speed of apron conveyors with a chain. This makes it ideal for retrofitting and modernizations. If operators want to increase the kiln capacity for example, they can replace an existing chain apron conveyor with a belt version of the same size, doubling the capacity without having to make any changes to the steel structure or the conveyor bridge. The cement plants also benefit from a new construction application: The thinner, lighter design of the GSZF reduces costs for steel structure and freight. Furthermore, the decreased net weight lowers the static and dynamic loads which affect the clinker silo and foundations. A new construction project can be designed for a smaller load and is therefore more cost-effective to build. The lightweight design also lowers operational costs.

The entire belt lies with its surface on the drive and return pulley which avoids the unwanted polygon effects caused by the chain. The particularly smooth running of the machine also reduces noise emissions considerably. The noise is less than half as loud as conventional SZFs with chains, which is advantageous for both the employees and the environment.

BEUMER Corp. USA, Somerset, NJ 732-893-2800 www.beumer.com

For related articles, news, and equipment reviews, visit our Mechanical Conveying Equipment Zone

Click here for Mechanical Conveying Equipment Manufacturers

Get information or register for Powder Show Toronto, June 4-6, 2019

You May Also Like