April 1, 2008

|

Roof of silo at fly-ash processing plant |

Ever overfilled a silo or bin? Many have. The costs associated with material spills resulting from overfilled bins can be substantial. What is the cause of overfilling a vessel? If a primary root cause of overfilled bins and silos can be identified and treated, companies will benefit by reducing their expenses, enhancing productivity and safety, and even improving the environment. Self-validating point-level sensors are tools that can be used to eliminate preventable overfilling.

The Problem

Most bulk-solids processors that have material contained in silos or bins use a high-level monitor (also known as a bin-level indicator) to control the filling operation. This type of device is considered a point-level sensor in that it monitors the presence and absence of material at a predetermined point. In this case, the predetermined point is a high level. Typically the switch-contact output of the high-level indicator is connected to a receiving device to indicate the high-level condition, or tied into the vessel-filling system to indicate that filling should cease or to automatically shut down the fill process.

There are several technologies that may be used for point-level monitoring. The most commonly used technology for general powder- and bulk-solids point-level monitoring is the rotary paddle. The rotary-paddle operation is quite simple and reliable. The unit is installed through the wall of a vessel so that the paddle protrudes into it. A small electric motor inside the unit’s enclosure drives the paddle (inside the vessel) that is connected to the output shaft of the unit. The paddle will rotate freely in the absence of material at the point of installation in the vessel.

When the paddle in the bin is impeded by material, the motor inside the enclosure rotates and triggers two switches. The first switch provides SPDT (one normally open and one normally closed) contact action that is available to control the filling system or an alarm circuit. The second switch is also SPDT and is used to cut the power to the drive motor, thereby preventing a locked rotor condition when material impedes the paddle and extending the life of the motor. When the material level in the vessel drops away from the paddle, a tension spring returns the motor to its original running position to reactivate the unit, and the switches return to their condition without material present.

|

Roof of silo at fly-ash processing plant |

The rotary paddle–level control is one of the simplest, most cost-effective, and reliable devices for powder- and bulk-solids applications. However, other technologies can also be used for high-level detection. These other technologies include RF capacitance, vibratory rods and tuning forks, and mechanical switches such as the pressure-sensitive diaphragm or tilt switch. But all are subject to failure at some point in time. That is one constant among all the devices available to monitor high-level conditions: They will all fail at some point in time.

Here lies the crux of the problem. What happens when a high-level control, the device used to shut off a filling system, fails? How does a company know it has a failed high-level control? The answer is obvious. A company finds out about its failed point-level sensor when it fails to shut off the filling system and the bin or silo is overfilled. A $200 to $300 device has now caused a catastrophe that will take time and cost lots of money. In fact, users have estimated that the cost of an overfilled silo can be as much as $5000. Consider the lost material, damage to equipment such as vents and filtering systems, cleanup costs, lost production time, and possible air-quality fines. The last item can get very expensive and be a very real problem if you overfill a silo with powder in a congested or residential area.

No matter what technology is chosen, when an unknown high-level-control failure occurs, there is a problem waiting to happen. So how can you avoid the costs associated with these unknown failures of the high-level sensor? Some have resorted to using fail-safe level monitors. After all, isn’t the idea of a fail-safe device to have the unit be in a safe condition if it fails?

How Safe Is Fail-Safe?

The Wikipedia definition of the term fail-safe is as follows: “A fail-safe or fail-secure device describes a device which if (or when) it fails, fails in such a way that will cause no harm or a minimum of harm to other devices or danger to personnel.” Sounds good, doesn’t it? However, those bin-level indicators or point-level sensors that promote a fail-safe function do not necessarily provide a function that meets this definition. Many point-level sensors labeled “fail-safe” that may be used for high-level detection typically only fail in a safe state if the power to the instrument were to fail. These include RF capacitance sensors and vibratory rods and tuning forks, as well as some rotary paddle brands. In the case of instrument failure as a result of internal-instrument mechanical or electrical causes, these so-called fail-safe devices will not fail safely or give any indication that they no longer work properly.

The only true fail-safe devices available for these high-level detection applications are those that are self-validating. These devices continuously monitor their internal ability to work properly; when they fail, they provide an output indicating their failed state. Conversely, this output can be monitored to indicate a healthy state. Self-validation provides true fail-safe functionality.

Safety Integrity Level (SIL)

|

Table 1: SILs and their measures of probable failure, risk reduction, and consequence |

Related to fail-safe functions in a level monitor is the subject of safety instrumented systems (SIS). This involves risk management, and ensuring safety through risk management is critical in some industries, especially where large-scale loss of life can occur, such as in chemical processing, refining, and pharmaceuticals, to name a few.

The International Electrotechnical Commission (IEC) has developed standards that detail SIS. IEC Standard 61511 was published to help users implement safety instrumented systems. In addition, the ISA 84 standard is published for the same purpose. ISA is the U.S.–based organization for standards in instrumentation and automation. An SIS is defined by Wikipedia as “an independent system consisting of sensors, logic solvers, final elements, and support systems.” An SIS is designed to maintain a safe state in a process system even when unacceptable conditions exist in the process.

The purpose of the SIS and all its components is to minimize risk. Sensors that can detect a level condition as part of a process could fall into the SIS. Each SIS can be evaluated to determine the safety integrity level (SIL) required. The SIL is a measure of how much risk to safety there is within a given process. Level sensors suitable for use in a particular SIL will have to exhibit less than a specified level of probability for a dangerous failure. The specific level is determined by the SIL number assigned. The IEC standard 61508 provides information on SIL levels. While the vast majority of bulk solids applications do not fall into the category of an SIS, it is important to be aware of the existence of these standards and what exactly an SIS is, as well as the various safety integrity levels (see Table 1).

The SIL is determined during the analysis of hazards within the process. Actually, this analysis determines whether an SIS is required and what safety instrumented function (SIF) is needed to take the process to a safe state with a specific SIL. The average probability of failure is used to determine the SIL.

Obviously, the potential consequences of an overfilled silo or bin are significant, but typically not nearly as severe as those associated with processes that necessitate safety instrumented systems and the use of instruments, such as point-level sensors, that meet the requirements of the respective SIL for the SIS they are in.

Self-Validating Point-Level Sensors for Bulk Solids

|

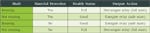

Table 2: Self-validating rotary-paddle state conditions |

Self-validating point-level sensors that are used as high-level detection devices enable an inventory management or control system to move to a safe state if these key sensors fail. When using a self-validating point-level sensor to protect against spills from overfilling, the sensor’s output should be directly tied to the control-system logic controller to take immediate action to stop or prevent filling until the sensor is placed back into a healthy functional state. Self-validating point-level sensors for bulk solids are available today based on only one technology. The good news is that the bulk solids’ self-validating point-level sensor is currently based on rotary-paddle technology. This technology is inherently simple, cost-effective, and virtually universal in application for powders and granular materials.

The self-validating, rotary-paddle, point-level sensor operates similarly to a standard rotary-paddle unit. However, it also has a method for monitoring output-shaft rotation and the initiation of material detection along with the built-in logic to determine whether the sensed actions are correct and, as a result, the unit is healthy and operating correctly. The common method for monitoring shaft rotation is the use of optical sensors. One brand uses a patented technique that applies Hall-effect sensors. This latter approach suggests improved reliability by eliminating optical sensors that can be fouled with dust and particulate. The Hall effect is not light-based and utilizes magnetic sensing elements and magnetic material. Either way, the logic for the sensor’s health status is the same (see Table 2).

The self-validating, rotary-paddle, point-level sensor typically uses a microcontroller for performing the logic analysis. The sensor provides two relays, one being for primary-material-level control and the second being for indicating the health status of the sensor. By monitoring the two outputs independently, a control system is able to differentiate between a failed sensor and a material control output or alarm. Some applications wire contacts from the two relays in series so that an alarm state is indicated upon sensor failure and material control. However, the control system cannot differentiate between the two possible causes for the alarm condition.

Rotary-paddle technology is a cost-effective point-level sensor.

The self-validating type of rotary-paddle device is also cost-effective as it is available for as little as $100 more than the price of a standard rotary-paddle unit.

Conclusion

The need for safety systems within many process industries is growing. Even in the area of inventory management and processing of bulk solids, safety is important. This is the area in which a self-

validating point-level sensor can provide benefits. The cost of a self-validating bulk solids point-level sensor is merely an extra $100 or so. Knowing immediately that your high-level sensor has failed is priceless. Don’t wait.

For more information, or if you have a question regarding the subject of this article, contact Joe Lewis at [email protected], and visit the company Web site at www.monitortech.com. You can also visit the Level Measurement blog at www.monitortech.typepad.com for information about a wide variety of level-measurement topics.

About the Author(s)

You May Also Like