April 8, 2016

At a mine or processing plant where dry bulk materials are stored in tanks, silos, and other vessels, it is important to know how much is inside each container for many reasons. These include:

• Manage inventory of raw materials, intermediate production, and finished product

• Manage process capacity to allow for flexibility in flow control

• Ensure safety for people, equipment, and the environment

Over the past decade, level measurement technologies have become more versatile, reliable, and cost-effective. Many users have upgraded manual, on-demand measurements and surveys to continuous, automatic level measurement and control. The benefits of these improvements include better inventory and process control, as well as improved personnel safety since workers don’t have to check by opening and looking in tank hatches.

While most of these advancements have been connected to liquid level applications, corresponding developments are now enabling similar improvements for level measurement of solids.

Get more information on Instrumentation & Control at the International Powder & Bulk Solids Conference & Exhibition, May 3-5, 2016

Solid versus Liquid Level Measurement

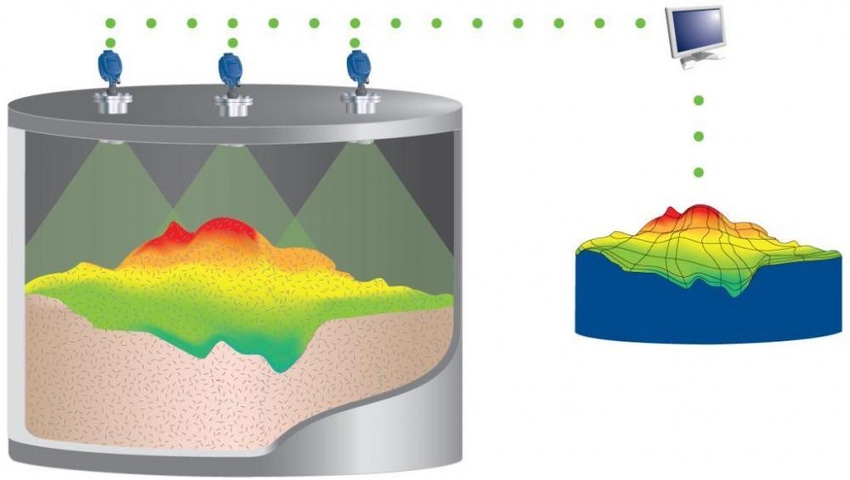

In a liquid application, a user simply needs to measure a single location on the surface because the level at one location is the same as any other location. This is not true with solids where the contents do not settle as completely (Figure 1), and the level at a peak may be very different from the level at a valley.

Depending on how much the material can pile before sliding – characterized as its angle of repose – and the width of the vessel, this peak-to-valley difference can be as much as 100%. Table 1 shows the angle of repose for typical solid materials (plus water for the sake of comparison, which of course is zero).

To understand how this affects operations, consider an example. The level at one location in a vessel may be 50%, but directly underneath the filling point a peak may have formed which reaches 100%. Looking at only the peak suggests additional material cannot be added so the vessel is effectively full.

However, directly over the emptying point, a “rathole” may have formed, so when an operator opens the drain port, nothing comes out. At that point the level is effectively 0% because no more material can be removed.

The average level can be anywhere between 0-100%, so it is impossible to use any single level measurement to judge how much material is actually in the vessel. Instead, the user should be concerned with maximum level, minimum level and total volume.

Technologies for Measuring Solids Level and Volume

Once a user’s approach shifts to measuring volume rather than level, a variety of technologies can be applied (Figure 2). The most common are radar (contacting and non-contacting), ultrasonic, and sonic (acoustic).

For solids applications, radar provides the greatest versatility:

• It delivers very fast response to changes in level, making it suitable for real-time closed-loop process control and safety applications

• The speed of radar is unaffected by changes in the vapor space—such as humidity, temperature, composition, or pressure/vacuum—providing better accuracy than speed-of-sound technologies.

• With appropriate heating or purging, radar can resist condensation and dusty environments.

• Contacting radar (guided wave) focuses the radar energy within the waveguide to maximize signal strength in difficult applications. Where contacting radar cannot be applied, for example where blocked by an agitator or vessel internals, non-contacting radar can often be used effectively.

• Radar waveguides and antennas are available in alloys able to withstand corrosive elements along with very high pressures and temperatures.

• Radar is rarely affected by interference because it uses a frequency range largely immune to noise from motors, conveyers, or other equipment.

• Contacting and non-contacting radar are familiar to most users from their widespread application in liquid level measurement.

Ultrasonic is appropriate in applications where the vapor space is consistent in composition, and where the temperature remains relatively stable or is controlled. Temperature is critical because it affects the speed of sound. While ultrasonic devices don’t have the broad operating temperature range or pressure range of radar (ultrasonic doesn’t work at all in a vacuum), it is suitable for many applications, even those with corrosive atmospheres.

Sonic (acoustic) designs are similar to ultrasonic, but operate at lower frequencies. This characteristic is particularly useful in dusty applications because low-frequency sound waves are absorbed less as they travel through dust than high-frequency sound waves (Figure 3). The short wavelengths of high-frequency sound waves are much smaller than the dust particles, so the vibrations are absorbed instead of being re-transmitted. The longer wavelengths of low frequencies are more comparable to the size of the dust particles, and vibrations occur slowly enough for most of the energy to be re-transmitted from particle to particle rather than absorbed. Acoustic devices can also be inherently self-cleaning. Like a loudspeaker driver, they push out bursts of air, driving dust particles away from the antenna.

A final benefit of lower frequency is a wider beam angle. In liquid applications, a narrow beam angle is usually preferred, since the tight beam can be aimed to avoid false reflections. This is especially important when the antenna is mounted up inside a tall spud (or nozzle) because reflections off the inside of the spud create noise which can overwhelm the true signal reflected off the liquid.

In solids applications, where the objective is to map as much as of the surface as possible, a wide beam angle is preferred. Wider beam angles require the unit’s antenna to be inside the vessel, rather than inside a spud, but when mounted in a good position, sonic devices can map more of the surface with fewer antennas. Even with wide beam angles, multiple antennas are usually required to obtain a complete wall-to-wall surface map in wide or irregularly shaped vessels, bins and silos (Figure 4).

To create a 3D model of the surface of a solid instead of a single level, the device needs to obtain x-, y-, and z-axis coordinates at multiple points on the surface. Similar to a GPS receiver, this triangulation requires at least three separate broadcast frequencies and receiving antennas. Once a detailed map of the surface has been obtained, total volume is calculated from the known vessel shape. Overall resolution and surface detail depends on the number of measuring points. Higher resolution provides a more precise volume calculation, but needs more processing power, which sometimes requires external data processing.

Improving Inventory Management

Although sometimes used for process control, most solids volume measurements in process industries are used to manage inventory such as raw materials, intermediates, and finished products. Companies with poor inventory management can run into problems if they don’t have an accurate picture of what is inside all those containers:

• Production slows or stops when feedstock runs out

• Production slows or stops because all the space for finished product is full

• Incoming feedstock deliveries must be rescheduled due to inadequate storage space

• Outgoing product deliveries must be delayed if inventory is not what was expected.

If a plant cannot measure the volumes of solid materials in various vessels accurately and reliably, any or all of those scenarios can happen. Some try to compensate by carrying additional safety stock, but this is very expensive. As shown in Figure 5, the cost of carrying inventory can be 25% per year or more of the value of the inventory, assuming the plant already has adequate storage space. Having to add more storage space will incur capital costs for the vessels, support infrastructure, and associated material handling equipment.

Improved online volume measurement-including accurate visualization of peaks and valleys-reduces the risks of overfilling or depleting a vessel. Over time, management gains confidence to reduce safety stocks, saving inventory costs. The benefit of reducing safety stocks is, of course, reduced carrying costs. Table 2 shows a sample calculation of the value of a 20% reduction in safety stock for a vessel holding calcium carbonate, assuming 25% annual carrying costs.

Conclusions

The surface of solid material contained in a vessel is typically uneven, so a level measurement at a single location on the surface does not provide much useful information. The most important step in building a better inventory management program is changing to a volume measurement approach instead of level.

The chosen technology—radar, ultrasonic, acoustic, or other—should be used to measure levels at multiple points on the surface and create a map of the surface from wall-to-wall within the vessel. With sufficient detail, this map can provide accurate volume calculation and best visibility regardless of peaks and valleys. Installing such capability requires capital investment, but the returns gained through more effective inventory management can recover those costs very quickly.

Mark Menezes, P. Eng., is Canada manager, Emerson Process Management. For more information, visit www2.emersonprocess.com.

Table 1 Source: Clover, T. J., 1995. Pocket Ref. Sequoia Publishing. ISBN 978-1885071002

You May Also Like