June 25, 2013

A specialist provider of grinding technologies for the mining, mineral, and cement industries, Cemtec (Enns, Austria) is using Insitec real-time particle sizing technology from Malvern Instruments to provide fully integrated, automated milling solutions that deliver high efficiency at competitive cost.

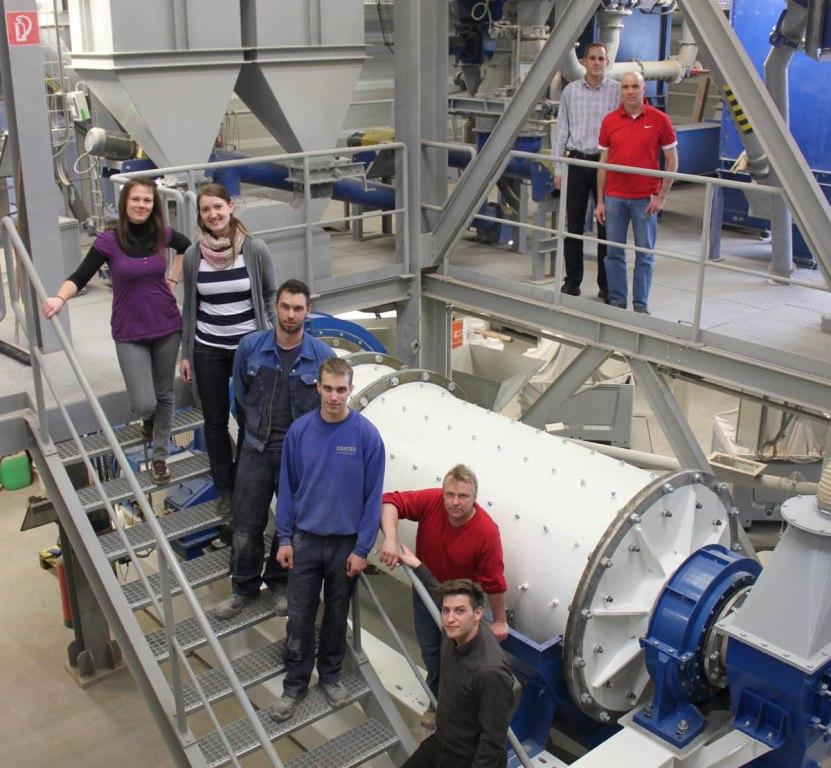

An exchange of equipment between the two companies has led to the installation of an Insitec system for the control of dry milling at Cemtec’s extensive pilot plant facility, and now customers of both companies can see for themselves how real-time particle sizing can transform process performance.

“Increasingly customers are looking for us to provide turnkey, often automated, milling circuits, rather than a stand alone mill,” said Franz Plochberger, head of R&D and process technology at Cemtec. “Timely particle size measurement is vital for efficient mill control, which is why we wanted to be able to integrate a trusted sensor within our processing solutions. Insitec is extremely reliable and enables us to provide milling plant that efficiently meets customer goals for premium product quality and low energy consumption.”

For related news, articles, and equipment reviews, visit our Instrumentation & Control Equipment Zone

You May Also Like