December 6, 2018

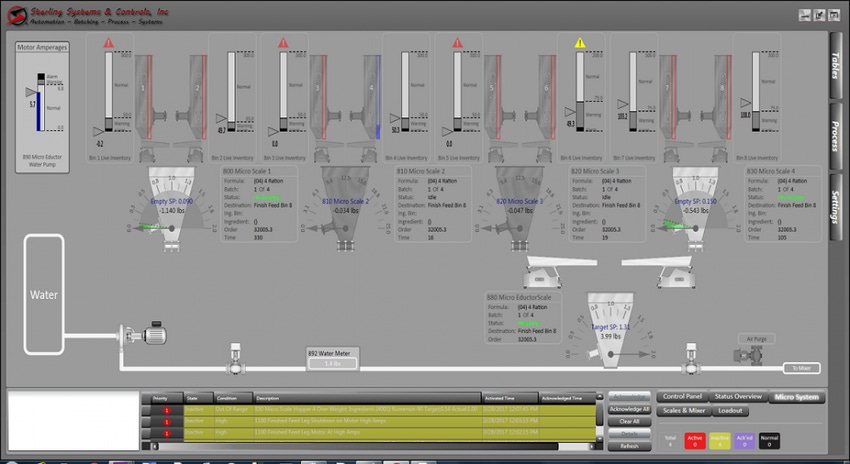

Sterling Systems & Controls announces that lot tracking, or ingredient material traceability, is available with all its batching process control systems and, like all other aspects of the offering, can be customized to meet the needs of the customer. Material traceability and batch validation can be instrumented on all semi-automatic hand-add, kitchen-type systems, or automatic batching control systems.

Background

Material lot tracking and traceability is a requirement in many industries, particularly in the food industry where there are large commercial sales for human consumption, and in the animal feed and pet food industries where chickens, cattle, hogs, horses, dogs, cats, etc. are mass fed or the feed/pet food is commercially sold. Many production facilities may get audited every few months, and in the animal feed industry the feed mill is required to present documentation or reports to the FDA showing their instrumented lot tracking and material traceability. When instrumented and equipped these reports come from the Sterling Systems & Controls feed mill, food, or pet food batching control system.

Customized Systems

Sterling Systems & Controls customized batching instrumentation and control systems can include as little or as much tracking and traceability as the customer wants to implement. It will depend on the customer’s ability to fund and implement the tracking system. Several inventory strategies are available. FIFO is the most common. Operators will be required to enter a valid lot number before the system will proceed. This data entry can be done by scanning a barcode, manual data entry, and by RFID. The batching control system will include an ingredient lot table. This contains records for each unique lot number of each ingredient. New records are added to this table when the ingredient is received.

Sterling Systems & Controls Inc., Sterling, IL 815-625-0852 www.sterlingcontrols.com

For related articles, news, and equipment reviews, visit our Instrumentation & Control Equipment Zone

Click here for a List of Instrumentation & Control Equipment Manufacturers

You May Also Like