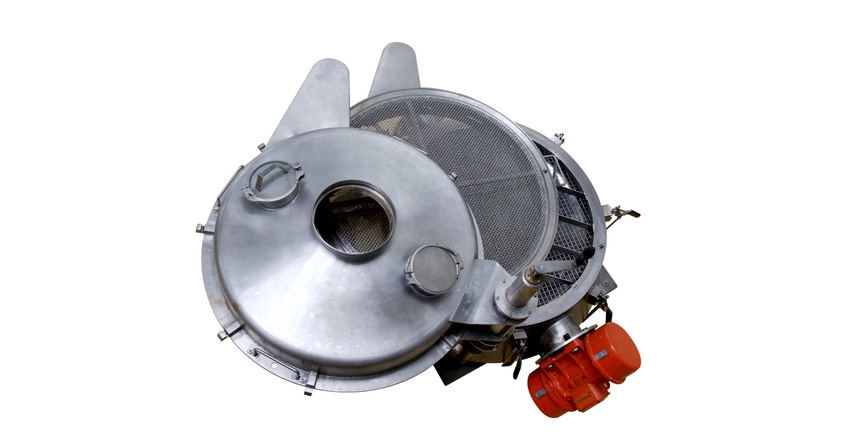

The GSC-ECD vibrating screener integrates all the features necessary for hygienic and easy to clean equipment.

April 28, 2021

The GSC-ECD vibrating screener integrates all the features necessary for hygienic and easy to clean equipment. All components are easily disassembled for the convenience of frequent clean down procedures. CIP wash nozzles can also be integrated on the inside of the vibrating screen. The materials used are FDA food grade compatible and corrosion resistant.

Vibrating sieves, or vibratory flat deck screeners, are typically used for quality control of food-based powders early in the production process, as well as at the end of a packaging line. The food industry provides a clean product by controlling the raw materials introduced into the process and by ensuring that the process itself does not generate foreign contaminants.

In addition, the design of Easy Clean Design (ECD) vibrating screeners offers almost zero material retention. Powder retention was a major design factor for the validation of this range of sifters.

The screener is designed to be dust-tight and prevent outside contamination. The atmospheric sealing of the screener allows sieving in a controlled atmosphere.

Palamatic Process Inc., Philadelphia, PA 215-498-9303 www.palamaticprocess.com/en-us

About the Author(s)

You May Also Like