July 22, 2019

EDEM, a market leader in Discrete Element Method (DEM) technology for bulk and granular materials simulation, has released a new version of EDEM BulkSim software - a specialized tool for designing and optimizing transfer points and chutes in the mining industry.

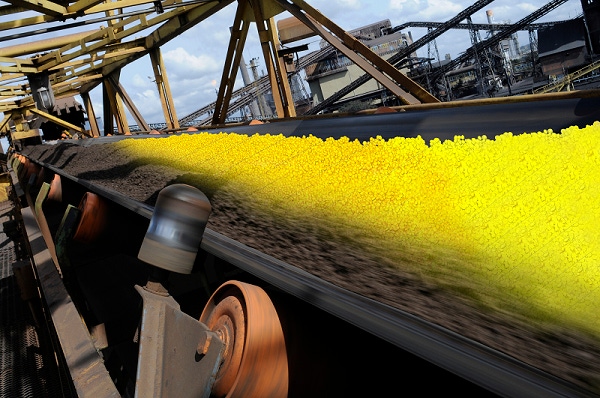

EDEM BulkSim has been developed for engineers designing transfer points used in mine operations and minerals processing plants, such as conveyors, chutes, stockpile reclaimers, and material feed and discharge chutes in comminution circuits. Although such systems account for a small percentage of the infrastructure cost of a plant or mine, poorly-performing transfer points are often responsible for significant operational challenges, resulting in unplanned down-time, reduced throughput, and lost productivity.

EDEM BulkSim simulation enables engineers to evaluate and verify the design performance of transfer points and chutes. By predicting bulk material flow and interaction with equipment components, it enables design engineers to identify and remedy potential problems in a design, such as material build-up and blockage, flow dispersion, spillage, size segregation, and excessive belt and chute wear — before commissioning. EDEM BulkSim has been designed for easy deployment across teams and includes a suite of out of the box visualization and analysis tools for both quantitative and qualitative evaluation of transfer points designs.

The latest version of the software includes a range of enhancements as well as increased capabilities and performance. EDEM BulkSim 2.0 includes a new user interface for quick simulation set-up and an intuitive workflow. Users now get access to the Generic EDEM Material Model (GEMM) Database to introduce materials in their simulation. The GEMM includes over 50,000 of pre-calibrated material models representing a wide range of rocks and ores. This means users get quick and easy access to fit-for-purpose material models that produce realistic material behavior and they can fully setup materials for a simulation without being a DEM expert. In terms of performance, users can expect a great speed-up with the possibility to run their simulation on their computers Graphical Processing Unit (GPU) - delivering simulation results up to 12 times faster than by using traditional desktop CPUs. On the post-processing side users benefit from faster data export and advanced tools to create more realistic and dynamic videos.

“EDEM BulkSim is a key design tool that enables engineers of all experience levels to get critical insight into transfer points performance,” said Mark Cook, product manager of EDEM. “It has been developed to easily integrate in the design process and means engineers can increase the quality of their designs by performing ‘virtual testing’ to assess performance under differing operating conditions. Version 2.0 means users can introduce materials quickly and easily by selecting a fit-for-purpose material model from our extensive materials library. Performance has also greatly improved which means users can run their simulations much faster and perform analysis quicker, leading to increased productivity.”

EDEM USA, Boston, MA 866-234-3336 www.edemsimulation.com

More articles that may interest you:

How to Simplify Bulk Solids Inventory Management

Transitioning to In-Line Powder Flowability Measurement

Uniaxial Powder Testing: A Simple Tool for Granulation Optimization

You May Also Like