April 23, 2014

Powder processing operations can generate vast quantities of electrostatic charge via the movement of powder. The standard method of charging on powder processing operations is due to tribo-electrification, which is basically the contact and separation of the powder with processing equipment, the powder itself, or other factors that can cause charging, like surface contaminants.

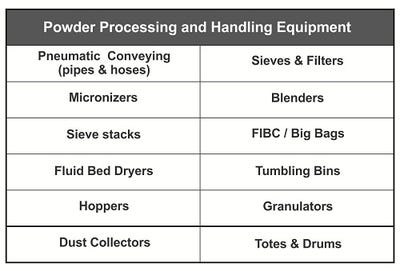

There are numerous types of equipment that can cause the charging of powders. Such equipment includes, but is not limited to:

Table 1: Equipment used in powder processing operations

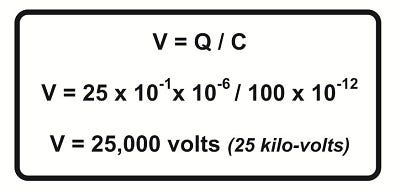

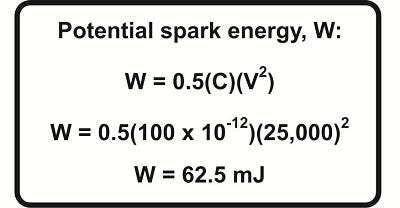

The potential energy that could be discharged from the drum in the form of a spark can be estimated to be:

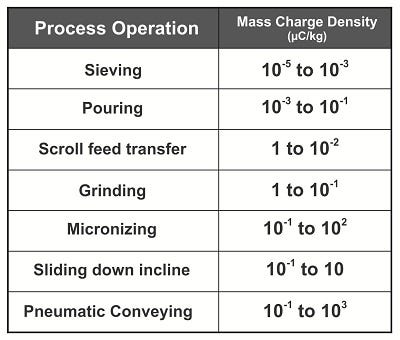

The processes carried out by such equipment can lead to varying degrees of electrostatic charge generation. Typical charge quantities, from published literature, are tabulated below. The values are based on the amount of charge, in coulombs, carried per kilogram of powder.

Table 2: Charge generated on powders by different powder processing and handling operations (NFPA 77 / CLCTR: 50404)

The potential energy that could be discharged from the drum in the form of a spark can be estimated to be:

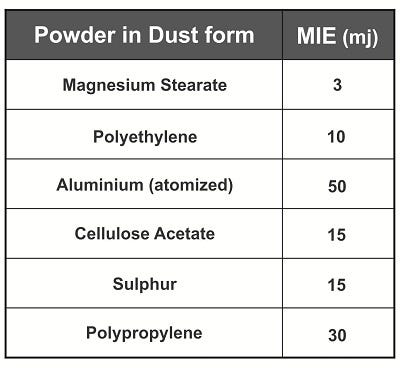

By any standard, the voltage generated by an operation that is known to be at the lower end of charge generating capacity can still generate enough potential spark energies to ignite a broad range of combustible atmospheres. Table 2 lists the minimum ignition energy of a sample of powders when they are at a minimum explosive concentration.

Table 3: MIE of various powders when suspended in a combustible concentration

If the powder is being discharged into a blender or mixer that contains a solvent, the MIE of the hybrid atmosphere could be much lower such that the initial ignition of the solvent vapor could propagate a combustible dust deflagration.

The safety factor that needs to be borne in mind with these calculations is the assumption that the equipment being “electrified” by the charged powder is not grounded. If the equipment is grounded, there is no risk of the equipment becoming electrified by static electricity.

Static Grounding Protection in Powder Processing Operations

In its truest form, “grounding” is the method by which a low-resistance electrical connection is made between equipment at risk of electrostatic charging and the general mass of the earth. This connection is normally described as a “true earth ground”. The actual connection to earth is achieved via purpose designed grounding rods, or building structures, that are buried below ground level. These grounding systems are tested by engineers to measure their true earth ground resistances to ensure they are below values required in standards like NFPA 70 “National Electrical Code” and EN 62305 “Protection Against Lightning”. Some static grounding systems on the market today will actually verify if the equipment they are providing static grounding protection for have a true earth ground capable of conducting static electricity.

In pharmaceutical operations, equipment like powder conveying systems, micronizers, blenders, and sieve stacks all make up multiple component assemblies that can accumulate high levels of electrostatic charge should any of the components be isolated from a true earth ground. Connections made with items like bonding straps can provide an intentional bond between metal components or assembly mating surfaces may provide an inherent bonded connection.

Fig. 1: A blender getting charged with a powder. Note that the bucket discharging the powder should be bonded to the receiving vessel or grounded independently.

Regular disassembly for cleaning and maintenance can result in bonding connections being missed or not made correctly when the equipment is reassembled. Vibration and corrosion may also degrade assembly connections so it is imperative to ensure that no parts in the assembly become isolated from a true earth ground reference.

The most effective way of ensuring that equipment used in powder processing operations cannot accumulate static electricity is to provide a dedicated static grounding solution that will monitor the ground connection of components at risk of static charge accumulation and alert personnel to a potential hazard should a component lose its ground connection. This is especially important if the ground connection point to the equipment is not readily visible or easily accessible.

Static Grounding Solutions: Convention Versus Flexibility

Most grounding solutions provide grounding protection for discrete pieces of equipment at risk of electrostatic charging like road tanker trucks, railcars, IBCs, and drums. For example, if a road tanker truck requires static grounding protection, a single static grounding system, featuring ground status indicators and interlocks for the pumping system, will be installed at the loading rack. If the ground connection is lost at any point during the road tanker truck filling operation, the grounding system will detect this and shut down the pump, or close a valve, feeding the road tanker truck.

Fig. 2: A dedicated static grounding system for road tanker trucks

Powder processing equipment presents more of a challenge as there are many metal parts that can make up larger assemblies that are electrically isolated from each other. For example, vibration pads that prevent mechanical destruction may be an inherent design feature, such that electrical isolation, by default, is inherent to the design of the equipment. In other cases, electrical isolation can be an unintended consequence of mechanical designs that have not have taken into consideration, or fully appreciated, electrostatic ignition hazards.

It is therefore important to ensure that multiple components that come into contact with charged powders do have a means of being monitored for static grounding protection purposes. This, however, may be easier said than done, especially if the processing equipment layout, available space and personnel accessibility is restrictive, such that multiple grounding systems may be difficult to install with such limited “real estate” to work with. The only alternative is for plant technicians to take regular measurements with ohm-meters to ensure that none of the plant equipment ever becomes isolated. For many operations this task is time consuming and results in technicians spending less time on critical maintenance and repair work.

Summary

In the powder processing industries, the generation and accumulation of static electricity presents an insidious ignition risk in potentially combustible atmospheres. The electrostatic charging mechanisms and corresponding quantities of charge generated are generally higher than those produced by petrochemical operations handling and processing flammable liquids. As such, it is imperative that all conductive components, be they members of machine assemblies or portable containers, have static grounding protection in place to prevent the accumulation and eventual discharge of static electricity as a high energy spark.

The installation of conventional static grounding systems, designed to monitor discrete equipment, like IBCs and road tanker trucks, are unlikely to be a viable solution for typical powder processing equipment like fluid bed dryers or sieve stacks. The quantity of systems required, the lack of available space and installation difficulty would either be too complicated, too expensive, or a combination of both.

For more information, visit www.newson-gale.com.

For related equipment reviews, articles, and news, visit our Explosion Protection & Safety Equipment Zone

Click here for information about the International Powder & Bulk Solids Conference & Exhibition

You May Also Like