January 8, 2020

On September 7, 2020, a major NFPA standard hits an important deadline. NFPA 652 – Standard on the Fundamentals of Combustible Dusts - requires all facilities and operations that handle combustible dusts or combustible particulate solids to have a completed Dust Hazard Analysis (DHA).

At Stonehouse Process Safety, as one of the leading North American process safety consulting and explosion testing facilities, we decided to quiz our clients and contacts to see how much they knew about the NFPA 652 standard and its requirements. So, at the end of 2019, we sent out a set of 10 questions via Stonehouse Process Safety Dispatch and invited those who wished to do so, to take a small blind test. Quiz conditions offered anonymity; the incentive was direct feedback to improve the understanding of those that responded.

We were delighted to discover that over 150 individuals elected to take our dust quiz. The participants had a range of roles from plant manager to safety personnel but the link between them all was an interest in process safety and dust explosion prevention and protection in particular. We felt that this number of responders was good enough to make the results statistically significant, and hence the idea to publish the results in Powder and Bulk Solids was born.

The quiz looked to discover how much is known about company obligations and responses, about who should do what – and about what to do after the DHA. We’ve listed the 10 questions below – and if any reader would like to take the quiz and obtain tailored responses to the questions, the quiz is still open and available at www.stonehousesafety.com.

The 10 Questions

1. I’m processing a very dusty powder. Do I have to comply with NFPA 652?

2. I’m processing combustible food powders. We have our own standard (NFPA 61). Do I still need to comply with NFPA 652?

3. I use flour in the kitchen at home. Do I have to comply with NFPA 652?

4. Who is responsible for determining the explosibility hazard properties of the powder I process on facility?

5. What testing do I have to have performed on my powder?

6. I have found dust explosion test data for my powder on the internet. Can I use that data for my DHA?

7. Do I have until September 7, 2020 to complete a DHA on my NEW facility?

8. Can I perform a Dust Hazard Analysis (DHA) myself?

9. Does the DHA have to be documented and submitted to the authorities?

10. I engaged a process safety consultant to perform a DHA for my facility. Have I now finished?

The Results

On average, respondents got two out of three questions correct -- not too bad an outcome perhaps. But there were a number of important areas that showed a definite misunderstanding of the requirements and obligations of NFPA 652. We look in turn at some of these.

We began the quiz with a seemingly simple (yet slightly devious) first question:

“I’m processing a very dusty powder. Do I have to perform a Dust Hazard Analysis (DHA) in accordance with NFPA 652?”

Most people answered a clear “Yes”. Only 30% of respondents spotted that you needed more information to answer this question properly! Maybe this question was a little unfair, but there are a number of important exemptions and situations where NFPA 652 does not apply. If the powder is not combustible, for example, then NFPA does not apply. Simple screening tests are available from the better commercial dust explosion test labs to establish if a powder is combustible. There are other exemptions as well and these are detailed in the responses seen by those who took the quiz.

Fortunately, most respondents understood that NFPA 652 does not apply at home in the kitchen. There were nine respondents who did feel they needed a DHA at home (or maybe hit the wrong response button). Of course, flour and confectioners’ sugar, for example, can - under the right conditions - ignite in our kitchens, too; it’s just that it’s not covered by NFPA 652.

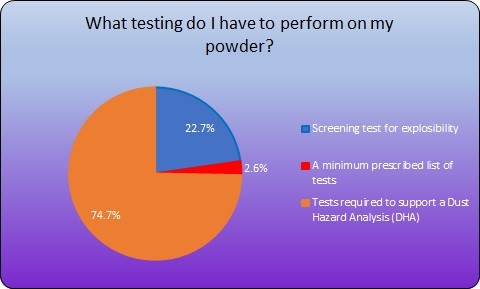

“What testing do I have to perform on my powder?”

Most people (75%) realized that combustibility testing may be required to support the DHA (see Figure 1)

Contrary to some belief, there are no specific tests demanded. Lab investigation can range from a simple screening test for simple processes through to a comprehensive set of tests that investigate properties as diverse a sensitivity to electrostatic sparks or hot surface “auto-ignition” - through to thermal stability testing. Determination of Kst and explosion pressure will likely be needed if explosion protection measures are employed such as explosion relief venting or explosion suppression. About half of respondents also realized that they may be able to use dust test data obtained from a public source such as the internet – but the public data MUST be for a dust that is identical in all key respects to the dust processed on their plant. Particle size and moisture content are just two of those properties that must match.

At Stonehouse Process Safety we like to discuss sample collection and laboratory test selection for DHA purposes with our clients. This is to avoid the commissioning of unnecessary tests – and equally to ensure appropriate test data is collected to support the DHA.

And on a similar topic, in answer to the question “Who is responsible for determining the explosibility hazard properties of the powder I process at the facility?” 44% of respondents did not realize that it was the responsibility of the owner/operator of the facility to obtain this test data. 39% of respondents believed the material supplier had some responsibility here.

We did ask if you needed to bring in an external expert to conduct the DHA on your behalf. 83% of respondents correctly identified that you could do the DHA in-house, but only if the assessor was sufficiently experienced/qualified.

Our final questions related to what to do once you had your DHA. Whereas 13% of respondents believed they had to submit their DHA to the authorities (incorrect), in answer to the question, “I engaged a process safety consultant to perform a DHA for my facility. Am I finished now?” a third of respondents believed they had finished.

(see Figure 2)

In fact, the DHA is really just a steppingstone towards the operation of a safe facility. NFPA 652 requires the hazards identified during the DHA to be addressed by developing an action plan to manage the necessary changes to process materials, physical process, process operations, or facilities. In addition, written safety managements systems would be needed to ensure continued safety of the operators, facility, and the community. This could involve things such as:

· written procedures for operating the facility and equipment to prevent or mitigate fires, deflagrations, and explosions

· training programs according to the potential exposure to combustible dust hazards and the potential risks

· The establishment of safe work practices to address hazards associated with maintenance and servicing operations – and their application to employees and contractors.

· A periodic walk-through review of operating areas and a schedule established to verify that operating procedures and safe work practices are being followed

Conclusion

It is clear that even those people with an interest in dust combustibility and NFPA 652 do not yet have a thorough understanding of the requirements of the standard – even as the clock counts down to the September 7, 2020 deadline. Perhaps this is not too surprising given that NFPA 652 is packed with technical detail throughout its 80+ pages. Nevertheless, there is still time to act to ensure compliance. A company such as Stonehouse Process Safety and others that have completed many DHA’s for clients may be able draw on practical experience to help fast-track you through to compliance in the timeliest manner.

Paul Cartwright, BSc, DPhil, CPhys is chairman and co-founder of Stonehouse Process Safety Inc. For more information on NFPA 652 or a dust hazard analysis, visit stonehousesafety.com or contact Stonehouse Process Safety at 609-455-0001 or [email protected].

More articles that may interest you:

What You Need to Know About the New Edition of NFPA 652

Extracting Combustible Dusts at the Source

How to Use Dust Explosion Test Data to Ensure Facility Safety

Explosion Containment: A Comparison

You May Also Like