June 3, 2020

Cole Solberg is business development manager, Aerodyne Environmental

When it is time to select a dust collector for your application, it is important that you ask the right questions. Not all dust collectors are the same. Some are very successful at removing large particulate, but less efficient with smaller particulate. Others are good removing small particulate but can have utility or maintenance issues with heavy loading. It is important to accurately define your process. The following questions will help select the most suitable dust collector for your process while avoiding common mistakes:

What is the airflow is required?

What is the volume of dust to be loaded?

What are the characteristics of the dust and how will its physical properties affect the dust collector?

Is the dust explosive and if so, has it been addressed in the dust collector design?

How will energy usage and maintenance affect the operating the dust collector?

Undersizing Your Equipment

The first question to ask, “What is the airflow your dust collector will see?” Without, accurately calculating the airflow, there is a good chance you will either oversize or undersize the collector. It is important to consider the ambient temperature of the air in the calculation. Many dust collectors are sized on actual airflow (ACFM) and not standard (SCFM). Oversizing has less effect on efficiency than under sizing the system.

However, undersizing your equipment is a major issue. Smaller dust collectors are less expensive, but they can cause more headaches and ultimately more money if undersized. Your dust collector will not process the airflow required when it is too small. When air enters a dust collector, the air usually slows down. Many times it must go through filters (baghouse and cartridge collector) or through a restriction (wet scrubbers). This causes a pressure drop across the dust collector. This pressure drop often increases as the airflow through the system increases.

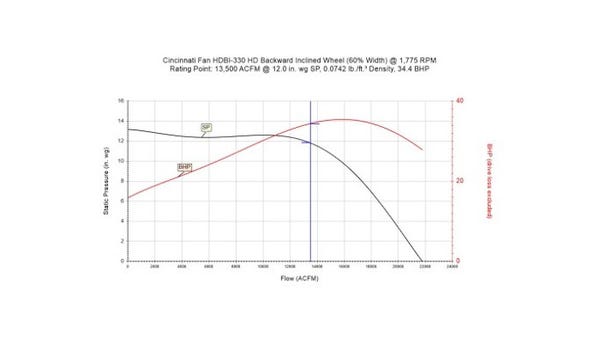

The dust collector system usually uses an exhaust fan to either push or pull the air through the system. This fan is sized to provide a specific airflow at a certain static pressure. Every exhaust fan has a performance curve, which shows what the static pressure will be at a specific airflow when the fan is rotating at a certain RPM (see chart).

When a dust collector is undersized, the pressure drop will be higher causing the fan to move less air, in accordance to the fan curve. Less air going through the system means that less air will be available at the pickup points to capture the dust. And if less dust is being captured, the dust is escaping into the facility causing health, maintenance, and safety issues.

One way to compensate for an undersized dust collector is to replace or change the exhaust fan. A well designed system often has an exhaust fan slightly oversized and controlled by a VFD so that it can be dialed into the correct speed required for the application and adjusted in the future if the process/conditions change. This allows the fan to move to a higher or lower curve, thereby changing the performance.

Not Factoring in the Dust Loading

The second important question to ask is, “What is the dust loading in the system?” Dust loading is important because if too much dust is in the air, it could cause operational issues. Usually the higher the efficiency of the dust removal, the more sensitive the equipment is to dust loading. Two examples are the baghouse/cartridge collectors and wet scrubbers. They both have high dust removal efficiencies and can remove particulate down to the sub-micron size.

Baghouse/cartridge collectors use filters to provide dust removal. The filters use a coating of dust to provide a porous barrier to the dust laden air. The air is drawing through the filters and any particulate in the air is stopped by the barrier. The greater the thickness of the barrier, the harder it is to pull the air through. This causes a greater pressure drop. Cleaning (compressed air, shaking, etc.) is usually done periodically to keep the barrier thin. However, with high dust loading, the dust buildup can overwhelm the cleaning, causing the filters to plug up (see photo). When filters plug up the airflow drops significantly, thereby not providing the dust collection at the pickup points.

The issues are different in wet scrubbers. A liquid (usually water) is used to help capture the dust. When a particulate meets a liquid droplet, the liquid droplet surrounds the particulate making a larger and heavier droplet which is then collected in the scrubber’s sump. This slurry is usually recycled back to the top of the wet scrubber to collect more particulate. As the system is operating, the concentration of solids increases in the slurry. When the slurry contains too high of a solids concentration, it will cause operational issues for the recycle pump and spray nozzles. To keep solids below this concentration, a blowdown stream is used to remove solids while make-up water is added to keep the liquid level constant. So the higher the concentration of dust coming into the wet scrubber, the more blow-down and makeup water will be needed.

One thing to note: Just because you have high dust loading, doesn’t mean that a baghouse or wet scrubber isn’t acceptable to use. Pre-filters, such as cyclones, can be used to capture the larger particulates, thereby lowering the loading, allowing the baghouse or wet scrubber to handle the smallest particulates.

Not Considering Your Dust Characteristics

The next question to ask is, “What are your dust characteristics?” Some dust is abrasive, which could cause equipment to wear out faster. Other dust is hygroscopic, which means it will grow when it becomes wet. Other dust becomes sticky when wet. Or a dust will cause corrosion of certain materials when wet, heated, etc. Fibrous dusts can cause their own issues. It is extremely important to define your dust and understand the issues it will have.

You then need to pick the correct dust collector to handle your dust. Dust collectors with filters will have issues with dust that become sticky or are hygroscopic if there is a chance water vapor is in the system (see picture). Fibrous dusts can stay in the airstream through cleaning cycles to cause early plugging. Abrasive dust can cause premature failure of the dust collector and/or accessory equipment such as airlocks, pumps, etc.

Even though your dust might give the preferred dust collector operational issues, it doesn’t mean the dust collector is unsuitable. You can control the environment and/or use a pre-filter to minimize issues in the collector. As an example, if the dust is hygroscopic and becomes sticky when wet, you can monitor the humidity in the airflow, and install a cyclone pre-filter to capture the larger dust. This will then allow your main dust collector to capture the smallest particulate and extend the time between maintenance.

Not Determining If Your Dust is Explosive

Is the dust explosive? This is almost a subset of knowing your dust characteristics, except that it is important enough to be classified by itself. Explosive dust can cause damage and injury, not only to a production line and its operators, but the entire facility. For this reason, local authorities and OSHA are concentrating more on explosive dust applications.

The basic guideline is that anything that burns has potential to explode. The smaller the particle size is and the more likely it is to oxidize, thus more likely to explode. The best way to find out if a dust is explosive is to get it tested. However, if you have test data from vendors or published data, you can use that too.

Some basic guidelines for explosive dust:

1) If you don’t know, test or ask a consultant

2) If in doubt, test

3) If you’ve seen fires in the process before, test. Just because it hasn’t caused an explosion before, doesn’t mean it won’t in the future.

If your dust is explosive, the testing will provide the values of Kst –Deflagration Index and Pmax – Maximum Explosion Pressure so that proper safeguards can be designed into the system. These could include explosion venting, chemical suppression, isolation valves, etc. (explosion vent shown in photo).

Not Evaluating Your Maintenance and Utility Usage

How will the maintenance and utility usage affect the dust collector? As we have discussed above, some material will cause increased material and/or utilities usage when certain dust collectors are used. When choosing a dust collector, consider the effect application’s conditions will have on maintenance frequency. If using a baghouse, replacement of filters and air valves may be more frequent. If you have an abrasive dust and are using a wet scrubber, you might have to replace piping and pumps regularly.

The utility usage should also be looked at. Wet scrubbers will require fresh make up water to be constantly added while the blowdown slurry is removed. The blowdown will have to be sent to a water treatment facility (plant or municipal) for further treatment. This will add to the cost of operating the dust collector.

Baghouses and cartridge collectors usually require compressed air to clean filters. The amount of compressed air adds to maintenance cost. And if the dust collected is sensitive to humidity, the cleaning process could cause operational issues when the compressed air isn’t dry.

Summary

To summarize, when selecting a suitable dust collector, consider the following factors:

Make sure you have accurately calculated the airflow and that the collector will operate efficiently at that value.

Calculate the dust loading that the collector will get. Make sure that the collector can handle the loading without causing operational issues or high maintenance and utility cost. If the dust loading is too high, investigate installing a pre-filter (i.e. cyclone) or using another technology for better efficiency.

Accurately define the dust characteristics and express them to the supplier. Some dust will have operational issues and could cause high maintenance and utility cost.

Test your dust to see if it is explosive if are any doubts. That way the dust collector can be designed correctly and safely.

Evaluate the dust collector maintenance and utility costs before purchasing.

Cole Solberg is business development manager, Aerodyne Environmental, Chagrin Falls, OH. For more information, call 440-543-7400 or visit www.dustcollectorhq.com.

You May Also Like