Clean air technologies create a safer world and stronger workforce

June 22, 2022

Bill Werra, president, C&W DustTech

Dust collection isn’t just about comfort. It is a critical process that directly impacts the long-term health and safety of your employees, assets, and surrounding communities.

Prolonged dust exposure in the workplace increases the risk of respiratory problems for employees--employees who are now increasingly prioritizing their safety when considering where to work. Likewise with consumers. In fact, 76% of consumers say they will discontinue partnerships with companies that treat employees, communities, and the environment poorly, according to PwC’s 2021 Consumer Intelligence Series Survey on ESG.

But underneath this challenge lies an opportunity: To help build a safer world and a stronger operation through efficient dust collection technology. The impact of dust collection systems on protecting people, communities, and the environment is often overlooked. So, let’s explore the ways that today’s clean air technologies can help companies like yours, as well as explore some fundamental tips for successful implementation of these systems.

1. Improving Employee Relationships

With a low unemployment rate, and job seekers considering many more factors when it comes to their next career move, it is harder than ever to find and retain quality talent. Companies that continue to focus on keeping their facilities clean, safe, and comfortable can have greater success in talent recruitment and retention.

Particularly in heavy industries, dust is a huge concern when it:

Presents risk of inhalation, increasing risks of respiratory, cardiac, and other problems

Blankets the floor, creating slipping hazards

Limits visibility at construction sites or production floors

A properly sized dust collection system can help you avoid these issues. Through clean air technologies, you can improve employee satisfaction, reduce turnover, and increase your competitive advantage – with happier, healthier, more productive employees who can visibly see your commitment to their safety and feel good to be part of your team.

2. Minimizing Hidden Costs – and Transforming Them into Cost Advantages

Every company is struggling with rapidly rising labor and equipment costs. Staying profitable in this environment requires that you find every opportunity to reduce costs. Capturing fugitive dust is one opportunity you should not overlook. In addition to being a safety risk, dust also leads to unnecessary expenses and waste. Dust settling on and in your equipment can cause premature breakdowns, and excessive dust in your ambient air can also lead to hefty regulatory fines for exposing workers and communities to these hazards.

A properly designed dust collection system can do much more than eliminate safety concerns. In many applications, you can design a system that can capture and recycle the collected dust back into the process – reducing waste and increasing your savings.

For example, “baghouse fines” from dust collection at concrete mixing plants are routinely recycled back as part of the mineral filler portion in asphalt paving mixtures. Since these “fines” are derived from naturally occurring aggregates (crushed stone, sand, or gravel), their properties are similar to those of mineral fillers, such as stone dust. Collecting this type of microscopic dust can add up to 40 tons of material back into a system. Simply put, by retaining these “fines,” the loss of aggregate is reduced and, therefore, lowering cost of maintenance and replacement of materials.

3. Increasing Production Efficiencies

When dust settles onto floors, machinery, workspaces, and more, it can cause all kinds of production problems: machine breakdowns, unexpected maintenance needs, enforced downtime or potential shutdowns due to non-compliance with emission regulations, and--in some cases--combustion risks.

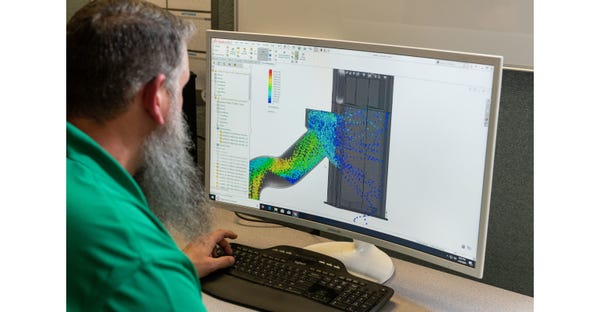

With fugitive dust posing several threats to your operation, look to a dust collection system not as a one-time expense, but as an investment that delivers a long-term ROI by helping to keep your plant up and running. The right system--complete with a properly sized dust collector, filter media, airflow, and setup--can be a tremendous asset for maximizing uptime.

It can also help exceed increasingly stringent regulations and standards set by the Mine Safety and Health Association (MSHA), Occupational Safety and Health Administration (OSHA). and Environmental Protection Agency (EPA) that control the amount of dust emissions permissible from your operations. Ensure your operation has the proper dust collection system in place to meet these requirements or face the risk of running into steep fines or a potential plant shutdown until you are able to get your emissions under control.

In addition, customizations can also match your specific needs for jobsite efficiency. For example, mobile dust collectors can help streamline workflow while improving air quality from site to site.

Tips for Successful Implementation

Getting an effective dust collection system isn’t as simple as picking one out of a catalog. Here are a few fundamental tips to keep in mind when starting the process.

Define your requirements

Regulatory, employee, and customer expectations are constantly evolving. Make sure you’re answering the following questions and defining your requirements to ensure you exceed these expectations today and for the future.

Ask yourself the following questions:

What type of dust are you collecting and how does it behave?

Can your dust be recycled and put back into the process?

What is the proper sizing, setup, and filtration needed for your application?

How are you meeting employee expectations for a safe work environment?

Where are your ideal pickup points?

How will the dust flow throughout your operation?

Invest in Maintenance

As with any system requiring continuous airflow, keeping your entire system clear of obstruction is crucial and an ongoing concern. Regular system cleaning and replacement of filters, inspecting reading gauges, and having an expert on-call, will ensure your systems run at maximum performance.

Consult with Dust Collection Experts

Don’t just guess. To implement a system that’s best suited to your needs, consult with dust collection experts that will walk you through these issues and customize the right system for long-term, bottom-line results.

Advancing the Opportunities of a Clean Air Future

Knowing the impact air quality has on your employees, your operation, your brand, and your community, don’t underestimate the difference an effective dust collection system can make. Follow these tips, talk to expert partners, and start driving meaningful change throughout your organization today.

Bill Werra is president, C&W DustTech (Alvarado, TX). For more information, call 800-880-3878 or visit www.cwdusttech.com.

You May Also Like