October 31, 2019

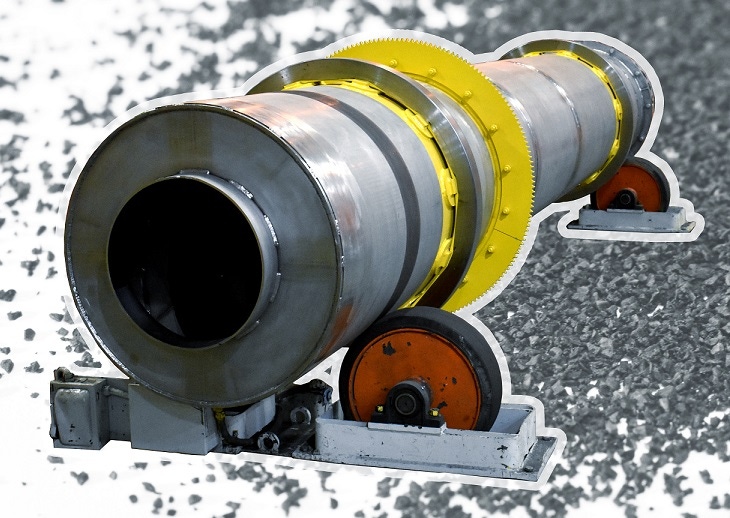

Engineers at Heyl Patterson Thermal Processing designed a smaller scale rotary dryer to be able to efficiently convey and dry small particles without running into the issues a customer was having with previous drying methods when they changed to a finer particle size. The custom internal lifter flights move and shower the small particles to prevent sticking or agglomeration while drying. This specialized design also produces minimum fines carryover in the exhaust gas. The rotary shell is 19 ft long and is constructed of stainless steel for ease of cleaning between use, and the inlet gas temperature is 300°F for optimal drying of the material without burning it.

Heyl Patterson Thermal Processing, Carnegie, PA 412-788-9810 www.hpprocess.com

Here are articles that may interest you:

Benefits of Tumble Blenders and Dryers

Algorithms: The Future of Vacuum Drying

The Basics of Drying: An Amalgamation of Science, Technology, and Art

You May Also Like